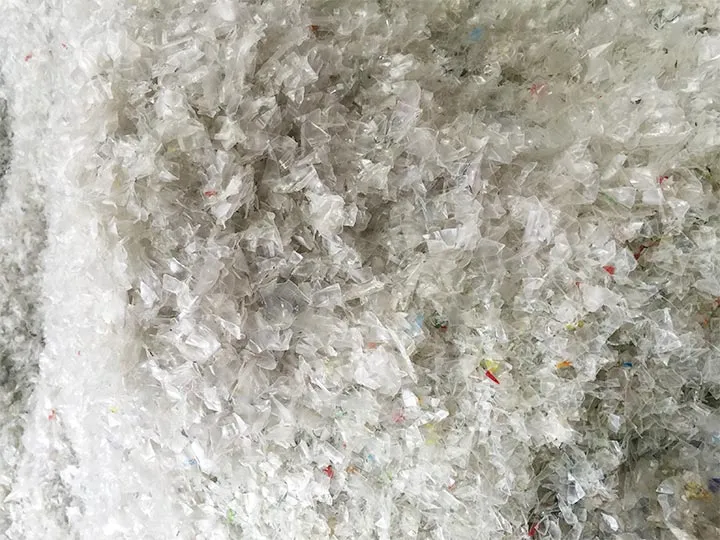

El tanque de lavado en caliente limpia las escamas de botellas de PET frotándolas entre sí mediante la agitación a alta velocidad de la espiral en la parte inferior. Las hojuelas de botellas de PET lavadas en caliente se pueden convertir en filamentos de poliéster.

Introducción al tanque de lavado en caliente

Los copos de botella PET con lavado caliente son un equipo necesario para producir copos de botella de grado alimentario o de grado fibra. Añadir esta lavadora de agua caliente a las líneas de lavado de plástico de PET, HDPE, PP, PE y otros puede eliminar eficazmente adhesivos, residuos de desecho, residuos de bebidas, olores y otros contaminantes.

Parámetros del tanque de lavado en caliente

- Lavar chips de PET con agua caliente y un agente de limpieza

- Potencia: 4 kW

- Tamaño: 1,3*2m

Principio de funcionamiento del tanque de lavado de botellas de PET

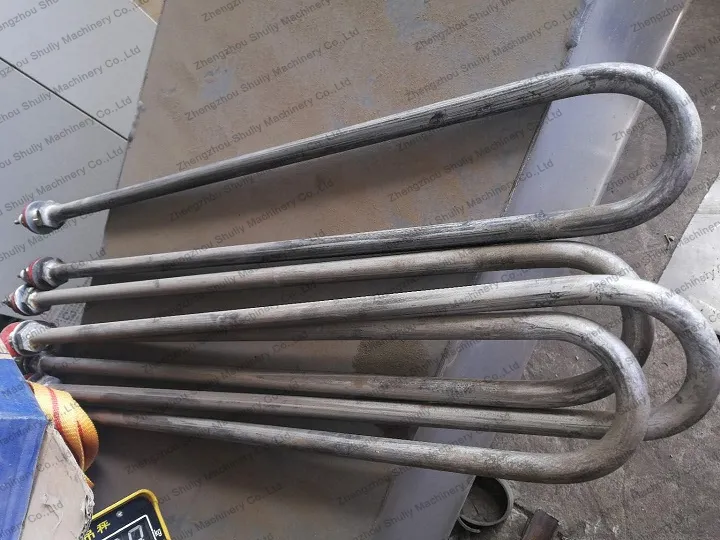

El lavador a alta temperatura para reciclaje de plástico realiza una limpieza profunda al colocar la hoja de plástico en agua a alta temperatura de aproximadamente 80-90°C y agregar soda cáustica o un agente de limpieza.

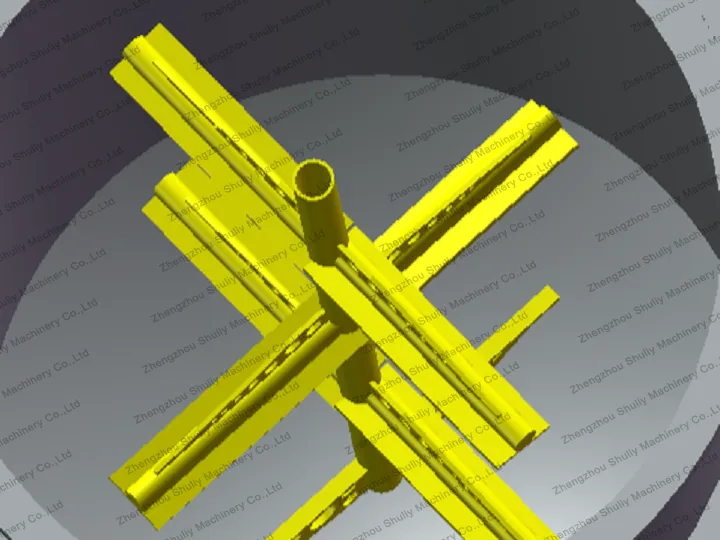

El tanque de lavado de botellas PET está equipado con un agitador accionado por motor, que agita continuamente el material y lo pone en contacto completo con el agua caliente, eliminando efectivamente contaminantes como aceite, residuos de etiquetas, pegamento, residuos de alimentos y otros contaminantes.

| Pasos | Detalles |

| Calentamiento químico: | El agua se calienta mediante un sistema de calefacción eléctrica mientras se añade soda cáustica o un agente de limpieza. |

| Agitación y lavado: | Dispositivo de agitación accionado por motor, agitando continuamente el material para asegurar una limpieza uniforme y completa. |

| Eliminación de contaminantes: | Un sistema de calefacción eléctrica calienta el agua mientras se añade soda cáustica o un agente de limpieza. |

Características de la máquina de lavado en caliente de copos de PET

- El diseño de descarga inferior, el agua y el agente de limpieza se pueden retener en el vaporizador de alta temperatura sin necesidad de retirarlos, lo que reduce la pérdida de agua y agente de limpieza.

- Fabricación de material de placa de acero gruesa, resistente al desgaste, resistente a la corrosión y mayor vida útil de la máquina de escamas de PET lavadas en caliente

- El calentamiento electromagnético, velocidad de calentamiento rápida, puede mejorar la productividad de una olla de lavado caliente

- Control independiente de control de temperatura, caja eléctrica, para proteger la estabilidad de la temperatura de calentamiento y el funcionamiento continuo y seguro de la máquina.

- Motor de marca, gran potencia y alta calidad.

- El dispositivo de agitación incorporado permite que el agente de limpieza y el trozo de botella entren en contacto completo, haciendo que la suciedad persistente se elimine más fácilmente.

Aplicación de la máquina de lavado en caliente de escamas de botellas de PET

La lavadora en caliente de escamas de PET se utiliza principalmente para el lavado a alta temperatura de escamas de PET, ABS, PC, HDPE y otras escamas de plástico duro.

Precauciones para el uso de la máquina de lavado con agua caliente

La temperatura y la duración del tanque de lavado de botellas de PET también afectarán el precio de las escamas de PET finales. La temperatura del agua en la máquina de lavado en caliente de botellas de PET se debe controlar mejor entre 85-95 grados, y el tiempo de limpieza es mejor que sea de 30-45 minutos.

Al usarlo, debe llenar el nivel de agua de la marca de agua, el proceso de trabajo debe reponer constantemente el agua perdida debido a la evaporación por calentamiento u otras formas de garantizar que el nivel de agua real esté en el nivel de agua de la marca.

¿Por qué los copos de PET necesitan lavado en caliente?

En aplicaciones textiles, por ejemplo, los copos de plástico lavados en frío pueden ser procesados en fibra de poliéster de corta longitud después del reciclaje. Después del reciclaje de plástico lavado en caliente, se puede convertir en fibra de poliéster de corta longitud o filamento de poliéster. La fibra larga de poliéster puede hacer todo tipo de ropa, textiles para el hogar, materiales decorativos y una variedad de productos industriales.

En el mercado, las escamas de botellas lavadas en caliente se reciclan en un tanque de lavado a alta temperatura a un precio más alto.

Tanque de lavado en caliente mejorando la calidad de escamas de PET en Sudán del Sur

El tanque de lavado caliente producido por Shuliy ha sido exportado con éxito a Sudán del Sur, y el tanque de lavado caliente ha sido instalado y puesto en funcionamiento en la fábrica del cliente. El tanque de lavado a alta temperatura ha sido instalado y puesto en funcionamiento en la fábrica del cliente. La máquina funciona de manera estable y tiene una alta eficiencia de limpieza, lo que mejora significativamente la limpieza y el valor añadido del reciclaje de escamas de botellas de PET locales, y ha sido altamente evaluada por el cliente.

"El tanque de lavado caliente funciona sin problemas y ofrece una limpieza a alta temperatura constante. Nuestros copos de PET reciclado ahora están mucho más limpios y cumplen con los estándares de exportación. Es eficiente en energía y fácil de mantener. Esta máquina ha mejorado realmente nuestra línea de producción."

— James Lado, Sudán del Sur

Máquina de lavado en caliente de copos de PET al por mayor

La función principal de un tanque de lavado caliente es eliminar eficazmente impurezas y residuos químicos de los copos de botellas PET, asegurando así la calidad del producto subsiguiente. Los fabricantes de máquinas de lavado caliente de copos PET al por mayor recomiendan que tenga una lavadora caliente de reciclaje de plástico en su línea de reciclaje de botellas PET.

Shuliy Machinery es un fabricante profesional de máquinas para escamas de PET lavadas en caliente con amplia experiencia en producción. Si desea trabajar en el negocio del reciclaje de plástico, no dude en dejar un comentario en el sitio web.