Для переработки вспененного материала EPE, Shuliy, как ведущий поставщик линий переработки пластикового пенообразователя, предоставляет передовые решения, помогающие болгарским компаниям эффективно перерабатывать пенопластовые отходы, одновременно создавая экономическую ценность.

Введение: Срочная необходимость переработки пенопласта EPE в Болгарии

С быстрым ростом электронной коммерции, упаковки и строительной отрасли в Болгарии, использование материалов из ЭППУ (пенополиэтилена) резко возросло в последние годы. Однако это также привело к резкому увеличению отходов из ЭППУ, создавая экологические проблемы, которые нельзя игнорировать. Поскольку Болгария согласовывает свои действия с экологическими нормами ЕС, переработка ЭППУ стала важным шагом к более зеленому будущему.

Обзор проекта: Полная линия гранулирования пенопласта EPE для Болгарии

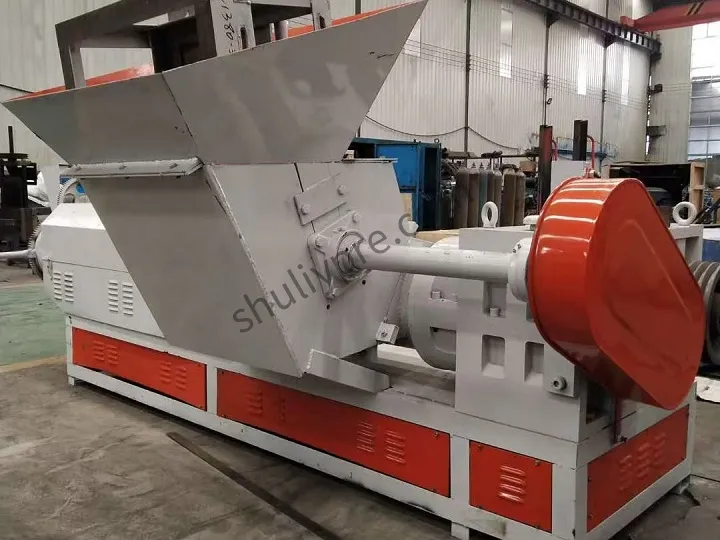

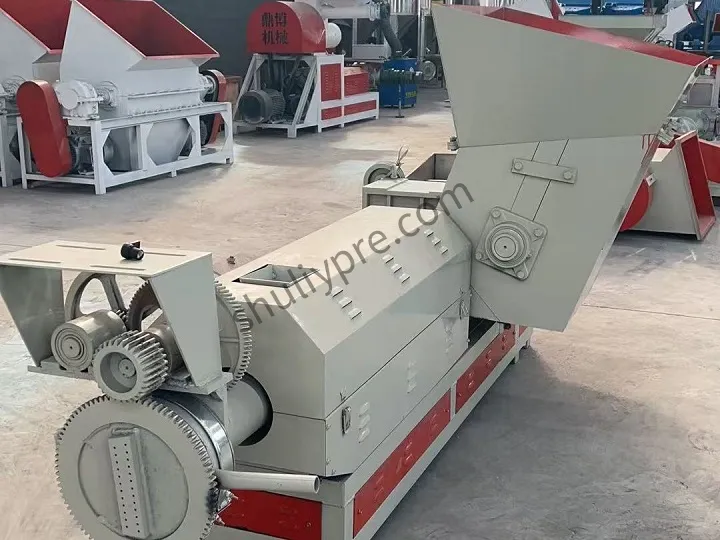

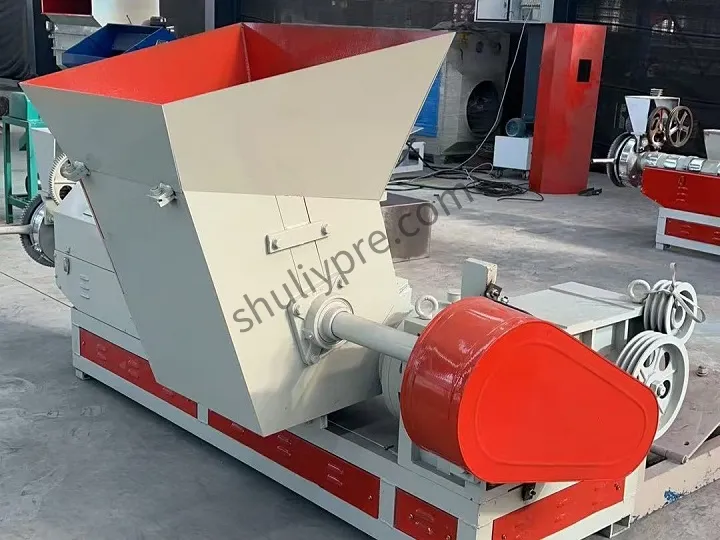

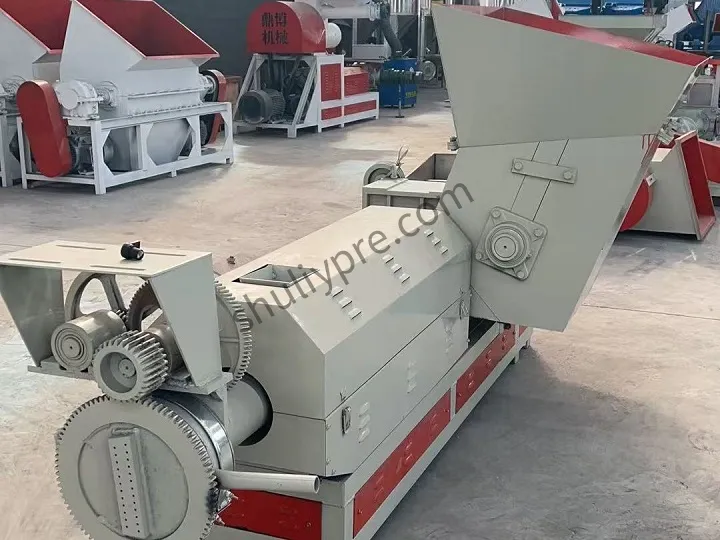

Недавно компания Shuliy предоставила болгарскому клиенту полную линию для гранулирования пластикового пенопласта, включая гранулятор, охладительную ванну и машину для резки гранул, разработанную для эффективной переработки EPE-пенопласта. Это решение позволяет клиенту производить высококачественные гранулы, подходящие для повторного использования в упаковке, защитных материалах и других приложениях.

Решение включало грануляторы из пластикового пенопласта Shuliy SL-160, предназначенные для средних производств. Производственная линия состоит из нескольких интегрированных компонентов:

Машина для гранулирования ЭПЭ пенопласта

Экструдер для пенопласта используется для плавления и экструзии небольших кусочков измельченного пенопласта в длинные полосы.

Охлаждающий бак

Охлаждающий резервуар используется для охлаждения высокотемпературных пластиковых полос, чтобы они затвердевали для облегчения резки.

Машина для резки гранул

Резак для пластиковых гранул используется для резки длинных полос охлажденного и затвердевшего пластика на пластиковые гранулы одинакового размера.

Эта конфигурация обеспечивает возможность переработки клиентом до 200 кг/ч отходов ЭППУ, превращая их в высококачественные гранулы, подходящие для повторного использования в защитной упаковке, изоляционных плитах и многом другом.

Обзор оборудования: Гранулятор пены EPE SL-160

Чтобы удовлетворить потребности клиента, Shuliy поставила машину для переработки пенопласта SL-160, надежную модель с устойчивой производительностью для производства среднего масштаба. Ключевые характеристики включают:

| Параметр | Ценность |

| Размер машины | 3400*2100*1600 мм |

| Размер входа | 780*780 мм |

| Мощность | 30 кВт |

| Производительность | 150-200 кг/ч |

| Метод нагрева | Тепловое кольцо |

Отзыв болгарского клиента о линии гранулирования Shuliy

Болгарский клиент похвалил машину для переработки вспененного полистирола SL-160 за её стабильность и качество выхода.

«Мы впечатлены работой машины SL-160. Ее мощность идеально соответствует нашим потребностям, а качество пеллет соответствует требованиям наших клиентов. Мы ценим техническую поддержку Shuliy во время установки.»

Доставка, установка и послепродажная поддержка

Машина для переработки вспененного полистирола SL-160 была отправлена с фабрики Shuliy. Все компоненты были тщательно упакованы, чтобы предотвратить повреждения во время транспортировки.

Наши инженеры предоставили исчерпывающее руководство по удаленной установке, что помогло команде клиента быстро завершить сборку и начать пробное производство. Мы также предложили обучение по эксплуатации и обслуживанию, обеспечивая долгосрочную надежность.

Машина для переработки пенопласта EPE: Специальный дизайн для переработки пенопласта EPE

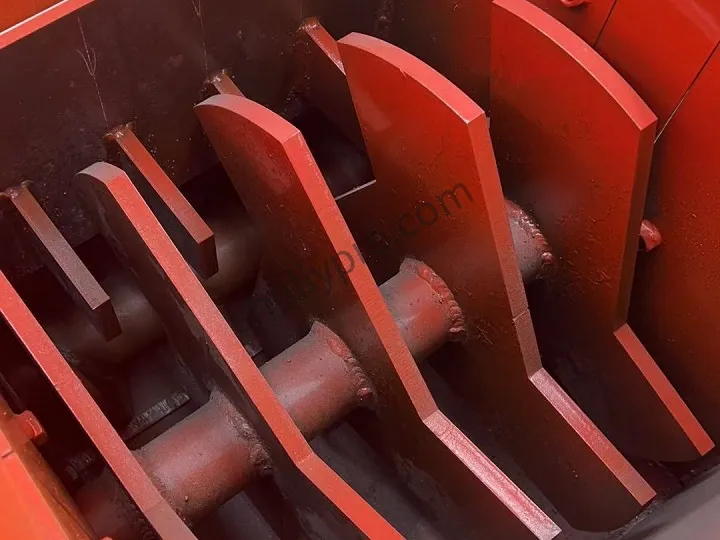

Пеллетизатор Shuliy для ЭПЭ - это специализированное решение, разработанное специально для эффективной переработки отходов расширенного полиэтилена (ЭПЭ). В отличие от универсального оборудования для переработки пластика, этот пеллетизатор для ЭПЭ спроектирован с учетом особенностей легкого, объемного и сжимаемого характера ЭПЭ.

Почему важен специальный дизайн EPE в переработке пенопласта EPE

- Объемная, легкая структура EPE-пены может вызывать засоры в стандартных машинах для переработки пластиковых пенопластовых гранул. Специальный дизайн для EPE обеспечивает плавную, непрерывную подачу без засоров, что позволяет осуществлять высокопроизводительное и стабильное производство.

- EPE требует определенной температуры плавления для эффективной экструзии и формирования гранул. Машина для гранулирования EPE-пенопласта оснащена интеллектуальными нагревательными кольцами и датчиками температуры, которые поддерживают оптимальный диапазон обработки, предотвращая деградацию материала.

- Из-за низкой плотности EPE машина не требует чрезмерной силы. Пеллетизатор для переработки EPE от Shuliy спроектирован так, чтобы обеспечить правильный крутящий момент и скорость, снижая потребление энергии при обеспечении надежного выхода.

Экологическая и бизнес-ценность переработки пенопласта EPE

Внедряя линию гранулирования пенопласта, болгарские предприятия получают как экологические, так и экономические преимущества:

- Минимизирует использование свалок — отходы пенопласта EPE преобразуются в гранулы, что снижает зависимость от свалок

- Поддерживает соответствие требованиям ЕС — соответствует целям по уровням переработки пластиковых отходов

- Снижает затраты на сырье — переработанные гранулы могут заменить первичные материалы во многих приложениях

- Укрепляет репутацию бренда — демонстрирует корпоративную ответственность и приверженность устойчивому развитию

Свяжитесь с Shuliy для решения по переработке пенопласта EPE

Shuliy предлагает комплексные решения для переработки ЭПЭ-пены, начиная от проектирования и производства оборудования до доставки, установки и послепродажного обслуживания. Позвольте нам помочь вам сократить затраты, повысить эффективность и внести вклад в защиту окружающей среды.

Если вас интересуют наши машины или вы хотите узнать цену на машину для гранулирования EPE, пожалуйста, свяжитесь с нами.