Машина для переработки стирофома эффективно решает проблемы переработки EPS-пены, интегрируя процессы дробления, плавления и гранулирования, чтобы преобразовать громоздкие отходы пены в плотные, пригодные для повторного использования гранулы, снижая загрязнение окружающей среды и создавая ценные сырьевые материалы для промышленности — универсальная линия для переработки стирофома, которая соединяет экологические потребности с коммерческой жизнеспособностью.

Свойства и характеристики пенопласта EPS и EPE

Экспандированный полистирол

EPS основан на полистирольной смоле в качестве сырья, в процессе производства используется вспенивающий агент в качестве вспомогательного реагента, а затем происходит нагревание при высокой температуре и образование пластикового пенопласта, который имеет уникальную, жесткую, замкнутую ячеистую структуру.

EPS имеет преимущества легкого веса, низкой цены, низкой теплопроводности, малого водопоглощения, хороших электрических изоляционных свойств, звукоизоляции, ударопрочности, влагостойкости и простоты процесса формования.

Почему стоит перерабатывать экспандированный полистирол?

Пенопласты EPS легкие, легко разлагаемые и трудные для переработки; миллионы тонн попадают в окружающую среду каждый год.

Они не только занимают земельные ресурсы, но и загрязняют воздух токсичными газами, выделяющимися при сжигании, и на их разложение в земле уходит сотни лет.

Но возникает вопрос: объем пены, низкая плотность, традиционный метод переработки неэффективен, как эффективно справиться с этой ‘белой загрязнением’?

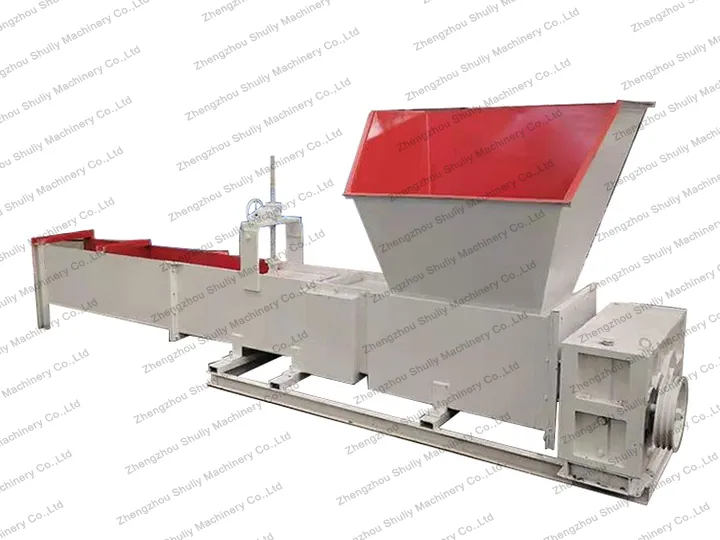

Решение для линии переработки EPS-стирофома

Ключ к решению проблемы эффективности переработки пены заключается в преодолении её физических характеристик: «большой объем и трудность сжатия».

Линия для переработки стирофома является индивидуальным решением для этой цели – через процессы дробления, горячего плавления и гранулирования пушистая пена сжимается в высокоплотные частицы, что не только значительно снижает затраты на транспортировку и хранение, но и превращает ее в перерабатываемое промышленное сырье.

Эта машина для переработки EPS не только отвечает требованиям охраны окружающей среды, но и реализует вторичную ценность разработки ресурсов.

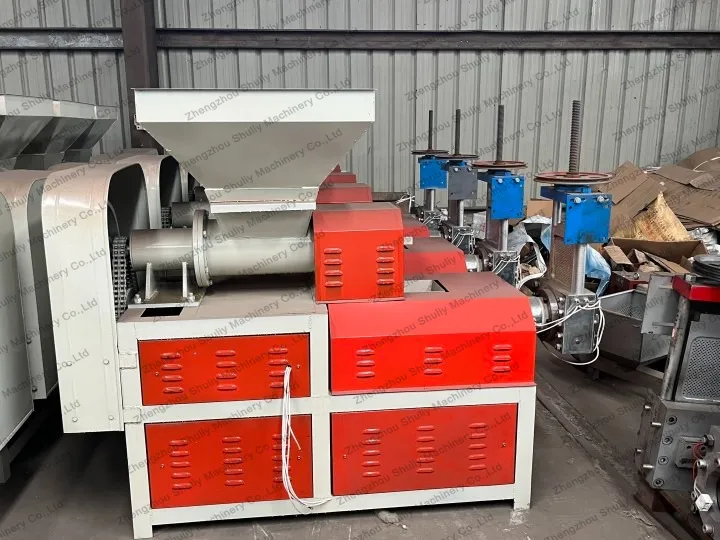

Рабочий процесс гранулятора EPS на продажу

Упаковка

Пенопласт EPS, измельченный механическим давлением через машину для компактации пенопласта, сжимает объем в 50-100 раз, снижая транспортные расходы.

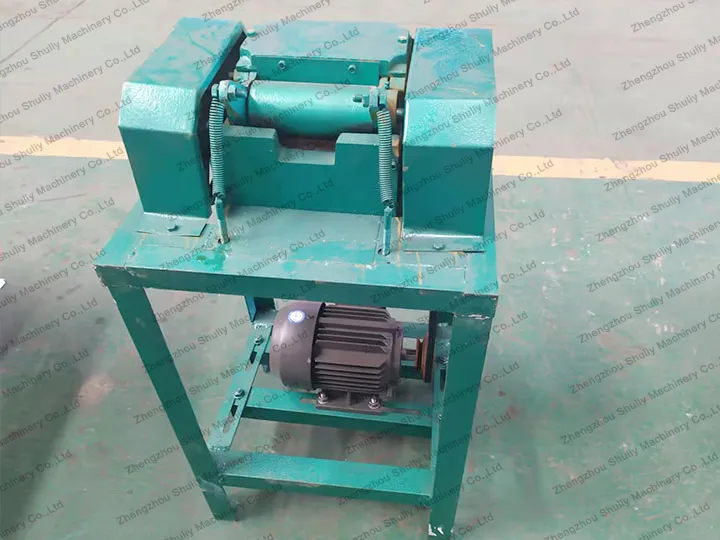

Дробление:

Дробилка для пластиковых пен разбивает крупную пену на мелкие кусочки размером 5-10 см, чтобы увеличить площадь поверхности для последующего нагрева и плавления.

Плавление и пластика:

Дробленный материал поступает в гранулятор ЭПС через входное отверстие и транспортируется в зону нагрева через вращение винта, а затем плавится в вязкую жидкость, одновременно удаляя остаточный воздух и следовую влагу.

Экструзия:

Плавленое вещество экструзируется через пористую пластину головки матрицы машины для переработки стирофома, а нити немедленно охлаждаются и затвердевают в водяном охлаждающем баке.

Резка:

Машина для резки пластиковых гранул разрезает нити на равномерные гранулы.

Хранение:

Однородные гранулы хранятся в контейнере для хранения пластиковых гранул, который позволяет им оставаться сухими.

Особенности линии гранулирования EPS-пены

Высококачественные гранулы: Разработаны с использованием первичных и вторичных машин для интегрированного производства, стабильная система нагрева оптимизирует молекулярную структуру материала, улучшая воздухопроницаемость и значительно повышая качество гранул машины для переработки пенопласта.

Долговечность: Установка гранулятора EPS состоит из дробилки, главного экструдерa и автоматической системы резки с натяжением, оснащенной автоматическим устройством смены экранов в главной машине для непрерывной фильтрации примесей. Как первичные, так и вторичные винтовые цилиндры машины изготовлены из высокопрочной углеродной конструкционной стали, что обеспечивает долговечность и стойкость к высоким температурам.

Быстрая подача: Оснащенная конусным шнековым цилиндром, машина для переработки стирофома обеспечивает быструю подачу и высокий объем выхода, что делает ее идеальной для эффективных операций по переработке пены.

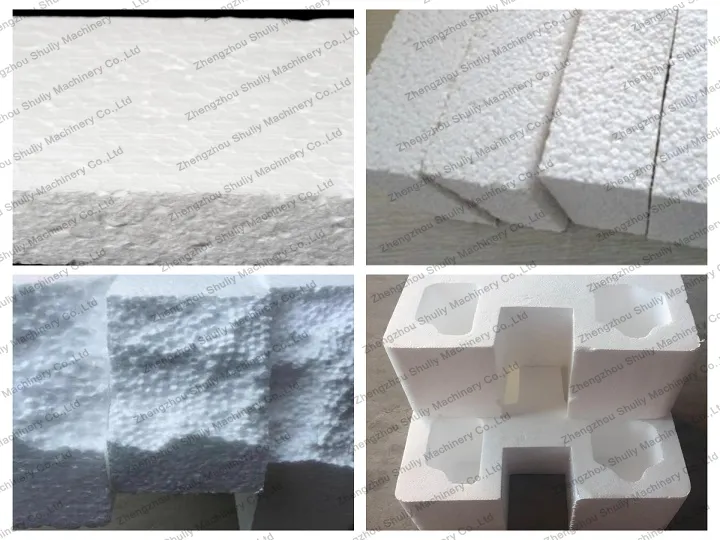

Конечные продукты гранулятора пластикового пенопласта

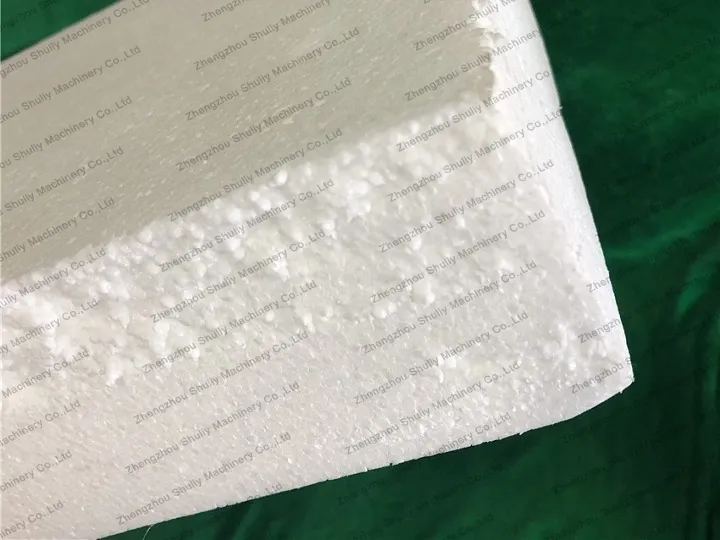

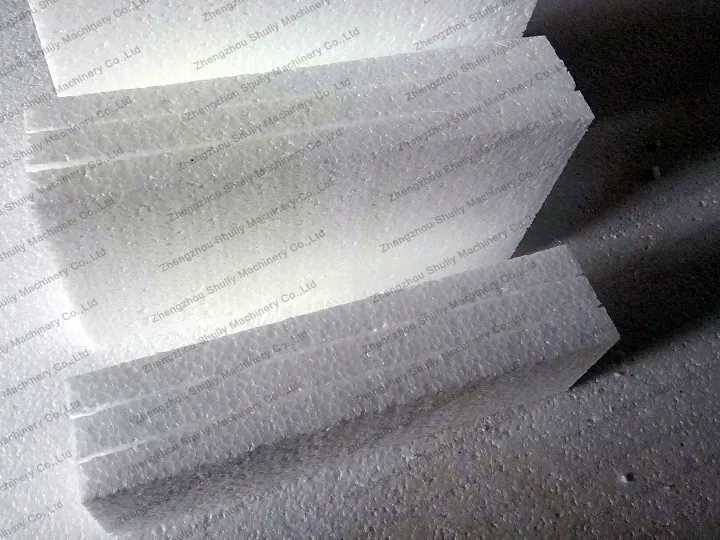

Переработанные гранулы EPS, производимые машиной для переработки стирофома, имеют регулярную цилиндрическую форму, в основном чисто белого или светло-серого цвета, а размеры могут быть гибко настроены в зависимости от фактического спроса путем изменения размера головки матрицы.

С помощью передового процесса плавления при высокой температуре и тонкой грануляции, машина для переработки стиропора Shuliy производит частицы с однородной текстурой и соответствующей плотностью, которые достигли значительного объема сжатия по сравнению с первоначальным пенопластом, обладают хорошей пластичностью и стабильной внутренней структурой, и могут быть точно адаптированы ко всем требованиям процессов формовки в последующей переработке.