提升脱水机是一种工业回收设备。通过螺旋混合、分离和脱水技术,脱水输送机可以自动去除湿材料中多余的水分,干燥度可达98%。

Shuliy Machinery是一家专业的塑料薄膜干燥机制造商,我们可以生产各种型号的干燥机。欢迎联系我们进行定制。

提升脱水机简介

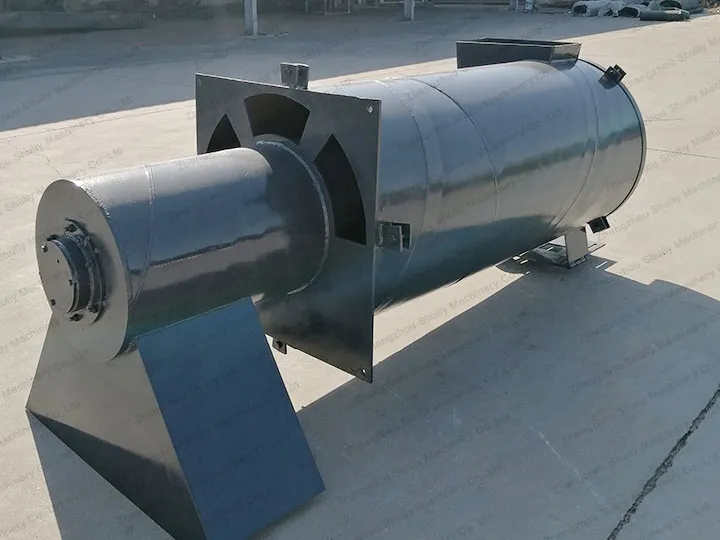

The lifting dewatering machine is located after the plastic crusher in the plastic film washing and pelletizing line. The dewatering machine is mainly used in the conveying process after rinsing. The plastic washing and drying machine feeding and discharging can be completed at one time.

塑料薄膜干燥机是如何工作的?

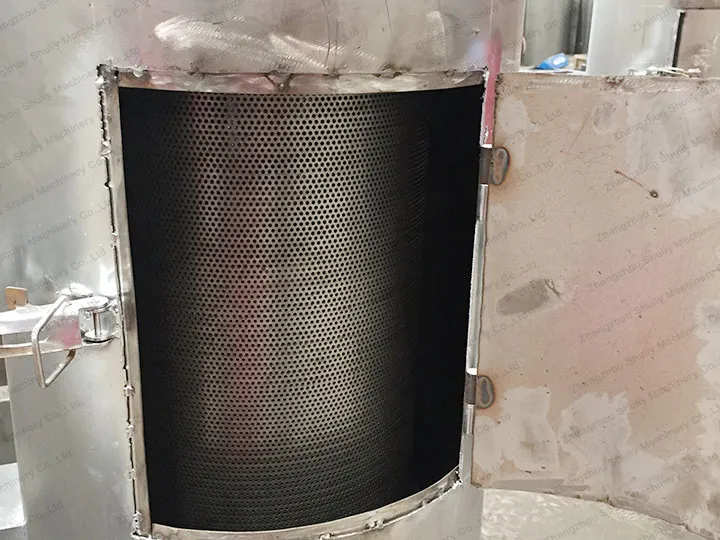

塑料薄膜干燥机的中心有一个装有多个面板或桨叶的长轴。在这个快速旋转的轴周围是一个筛选通道。

塑料废物干燥机通过高速旋转的垂直轴利用离心力将水从湿材料中分离。干燥后的塑料通过出口排出。

塑料废料干燥机工作过程

湿料进入塑料废料干燥机后,内部轴高速旋转。脱水输送机通过离心力将水分与塑料薄膜分离。

提升脱水机旨在去除洗涤后的塑料材料中的水分——如PET片、HDPE瓶片、PP薄膜废料及其他塑料废物——以便在进一步加工如造粒或注塑之前进行处理。其工作原理基于高速离心脱水与热风干燥相结合,确保塑料片或碎片高效达到所需的低水分含量。

高速离心脱水

湿塑料材料被送入干燥机的脱水部分,在那里,一个快速旋转的轴带着刀片产生离心力。这个力将塑料片表面的水分甩掉,因为它们以高速旋转。

热风辅助干燥

经过离心脱水后,塑料材料进入热风通道。加热的空气通过塑料流动,蒸发任何剩余的水分。空气的温度和流量被精确控制,以防止材料变形。

最终排放

干燥的塑料片或碎片在出口处排出,水分含量通常低于5%,使其准备好进行造粒、挤出或储存。

为什么塑料需要干燥?

大多数塑料原材料会有少量的水分吸收,例如在干燥过程后,如果未进行干燥,所制成的产品会出现水痕、尺寸不稳定等各种问题。塑料脱水机可以帮助您解决这个问题,确保成品的质量。

塑料废料清洗和干燥机的应用

塑料废料清洗和干燥机在现代塑料回收厂中发挥着至关重要的作用。它旨在清洗和干燥各种类型的消费后和工业后塑料废料,为进一步加工(如造粒、挤出或注塑)做好准备。

塑料脱水机可用于干燥碎片和清洁的塑料薄膜,包括编织袋、蛇皮袋、吨袋、垃圾袋、零食袋等废塑料。

脱水输送机输出

塑料废料清洗和干燥机的产量为1000-1500公斤/小时。Shuliy Machinery目前的热门型号是SL-500和SL-600,功率分别为7.5千瓦和15千瓦。

此外,我们还可以根据您的需求定制机器型号。如果您需要塑料废料干燥机,请与我们联系。

提升脱水机常见问题

使用塑料废物干燥机后,材料干燥程度如何?

塑料废料干燥机可以将水分含量降低到2%以下,满足颗粒化、挤出或注塑的要求。

塑料废料干燥机可以集成到完整的回收线中吗?

绝对是的。塑料废料干燥机旨在与破碎、清洗和造粒设备无缝集成,形成完整的塑料回收生产线。

如何维护提升脱水机?

定期清洁塑料洗衣机的过滤网和排水口,并检查塑料烘干机的轴承和加热系统,以确保其顺畅运行

询盘

如需了解最新的塑料废料洗涤和干燥机价格和交货条件,请在网站上给我们留言。