مع تزايد الوعي البيئي، تستثمر المزيد من الشركات والحكومات في مصانع إعادة تدوير البلاستيك. فكيف تعمل مصانع إعادة تدوير البلاستيك؟

التلوث الناتج عن فيلم البلاستيك هو تحدٍ بيئي عالمي. بناء مصنع إعادة تدوير بلاستيك فعال من حيث التكلفة والكفاءة يعزز دورات الموارد والمكاسب الاقتصادية. على وجه الخصوص، يعتمد إعادة تدوير أفلام البلاستيك الفائضة على خطوط تقطيع وتكسير الفيلم البلاستيكي المتخصصة، وهي تقنية رئيسية في قطاع إعادة التدوير اليوم.

ما هو مصنع إعادة تدوير البلاستيك؟

مصنع إعادة تدوير البلاستيك هو منشأة يتم فيها فرز مخلفات البلاستيك وتنظيفها ومعالجتها وتحويلها إلى مواد خام قابلة لإعادة الاستخدام. السؤال الأساسي - كيف تعمل مصانع إعادة تدوير البلاستيك؟ يمكن الإجابة عليه من خلال فحص كيفية تعاملها مع البلاستيك من النفايات إلى الحبيبات النهائية الجاهزة للإنتاج.

المعدات الأساسية في كيفية عمل مصانع إعادة تدوير البلاستيك

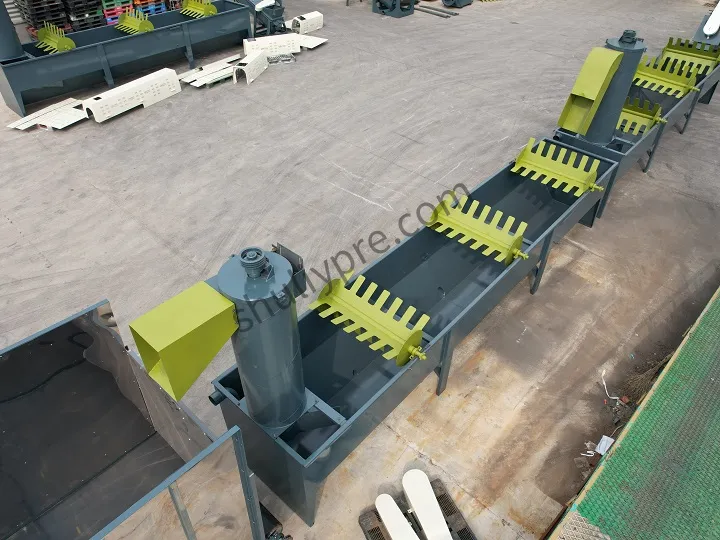

اختيار الآلات المناسبة يحدد كفاءة وفعالية تكاليف مصنعك. قد يتكون خط إعادة تدوير البلاستيك النموذجي من:

| المعدات | وظيفة |

| ماكينة طحن البلاستيك | يقطع أفلام البلاستيك إلى رقائق بحجم 10-20 مم، ويمنع التشابك أثناء الطحن. |

| ماكينة غسيل بلاستيك | يزيل الأوساخ من الرقائق باستخدام الماء الساخن والاحتكاك. |

| آلة نزح المياه العمودية | يزيل الرطوبة من الرقائق عبر التجفيف بالطرد المركزي والهواء الساخن. |

| ماكينة تكوير الفيلم البلاستيكي | يقطع أفلام البلاستيك إلى رقائق بحجم 10-20 مم، مما يمنع التشابك أثناء الطحن. |

كيف تعمل مصانع إعادة تدوير البلاستيك؟

عند النظر في كيفية عمل مصانع إعادة تدوير البلاستيك لإعادة تدوير أفلام البلاستيك، تحتاج إلى معدات خاصة مثل كسارات مضادة للتفاف، وغسالات احتكاك محسّنة، ومجففات عالية الكفاءة. تتطلب أفلام LDPE و HDPE الرقيقة معالجة دقيقة لمنع انسدادها وضمان نقائها.

التغذية والسحق

تُقطع أفلام البلاستيك المهدرة إلى رقائق بحجم 10-20 مم بواسطة كسارة أفلام بلاستيكية مضادة للتشابك. تمنع الدوارات ذات السرعة المنخفضة، والكاشطات، والشاشات المصممة بشكل صحيح التشابك، مما يضمن إنتاجًا مستمرًا ومستقرًا.

غسل

تستخدم غسالات البلاستيك الماء الساخن والمنظفات والاحتكاك الميكانيكي لتنظيف الرقائق بشكل كامل. سؤال شائع هو كيف تعمل مصانع إعادة تدوير البلاستيك لضمان مخرجات نظيفة؟ تكمن الإجابة في الغسيل متعدد المراحل: تزيل غسالات الاحتكاك الغراء والأوساخ، بينما تفصل خزانات الطفو الملوثات الخفيفة.

إزالة الماء والتجفيف

تستخدم آلة تجفيف البلاستيك قوة الطرد المركزي عالية السرعة وتجفيف الهواء الساخن لإزالة الرطوبة السطحية، مما يقلل من محتوى الرطوبة إلى أقل من 1%، مما يعد المادة للتكوير.

البثق والتكوير

تدخل الرقائق المجففة إلى آلة البثق ذات اللولب المفرد أو المزدوج المجهزة بتغذية قسرية ومغير شاشة هيدروليكي. تذوب البلاستيك بشكل متساوٍ ويتم تقطيعه بواسطة قاطع حبيبات عالي السرعة إلى حبيبات متساوية وناعمة، ثم يتم تبريدها وتعبئتها.

الأثر البيئي والفوائد: كيف تعمل مصانع إعادة تدوير البلاستيك

فهم كيفية عمل مصانع إعادة تدوير البلاستيك يبرز دورها الإيجابي في حماية البيئة. تم تصميم هذه المصانع للحد من تلوث البلاستيك من خلال تحويل النفايات البلاستيكية إلى مواد خام قيمة من خلال عملية إعادة تدوير البلاستيك. كل مرحلة - من الفرز والغسيل باستخدام آلة غسل البلاستيك إلى التكوير باستخدام آلة تكوير البلاستيك - تساهم في تقليل النفايات في المكبات وتلوث المحيطات.

تقليل نفايات البلاستيك في المدافن والمحيطات

عندما تفهم كيف تعمل مصانع إعادة تدوير البلاستيك، يصبح من الواضح أن إعادة التدوير تقلل من الحاجة إلى إنتاج البلاستيك الخام، مما يحافظ على موارد النفط والطاقة.

تقليل انبعاثات الكربون

تقلل محطة إعادة تدوير البلاستيك المصممة بشكل جيد مع آلة تشكيل الحبيبات البلاستيكية الموفرة للطاقة وغسالة البلاستيك الموفرة للمياه بشكل كبير من انبعاثات الكربون مقارنة بإنتاج البلاستيك الخام.

دراسة حالة: خط إعادة تدوير أفلام LDPE البلاستيكية تم شحنه إلى بوتسوانا

تساعد هذه الحالة في توضيح كيفية عمل مصانع إعادة تدوير البلاستيك في الإعدادات الصناعية الحقيقية. في أوائل عام 2024، قامت شركة شولي ماكينات بتسليم خط كامل لإعادة تدوير أفلام البلاستيك LDPE إلى عميل في بوتسوانا.

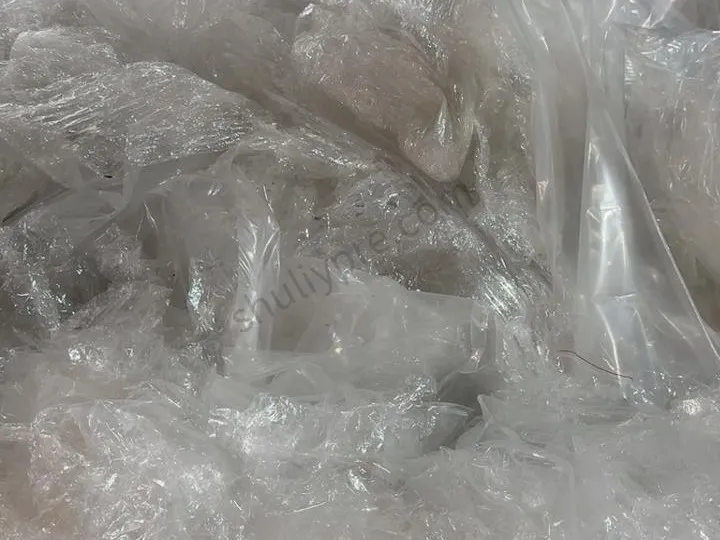

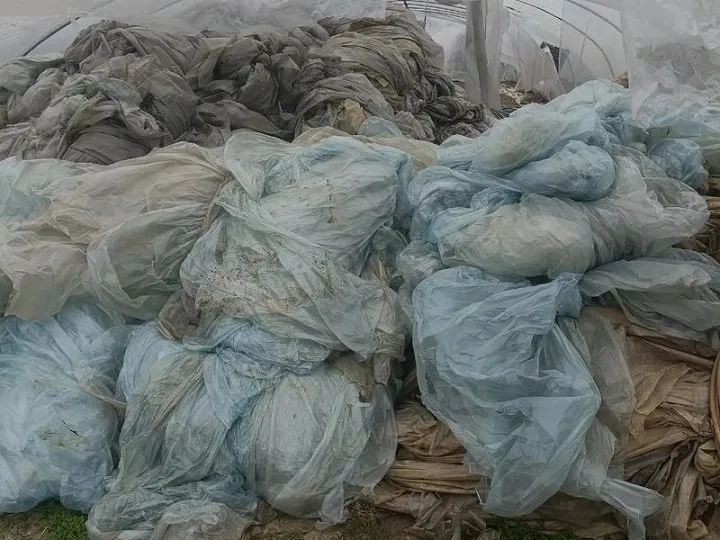

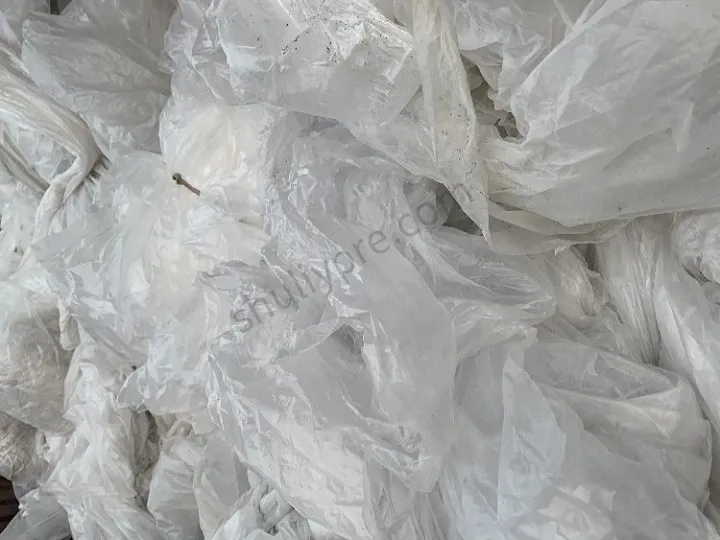

المادة الخام للعميل كانت تتكون أساسًا من أفلام زراعية وأفلام تعبئة تحتوي على مستويات عالية من التلوث. كان الهدف من المشروع هو تقليل النفايات البلاستيكية المحلية وتعزيز الاستخدام المستدام للموارد.

| عنصر | التفاصيل |

| موقع العميل | تم تزويد مصنع إعادة تدوير البلاستيك لبوتسوانا. |

| نوع المادة | فيلم زراعي بشكل رئيسي وفيلم تعبئة مع مستويات تلوث عالية (LDPE). |

| المعدات الأساسية | كسارة فيلم بلاستيكي، نظام غسيل ساخن، غسالة احتكاك، آلة تجفيف البلاستيك (نوع الطرد المركزي)، آلة تشكيل حبيبات البلاستيك (برغي مفرد). |

| أبرز التصميمات | تصميم معياري، محركات موفرة للطاقة، نظام إعادة تدوير المياه، مغير شاشة هيدروليكي. |

| ملاحظات العملاء | أشاد العميل بالعملية المستقرة، وجودة الحبيبات العالية، وانخفاض تكلفة التشغيل. |

من خلال التواصل المفصل، قمنا بتخصيص حل إعادة تدوير عالي الكفاءة يتضمن التكسير والغسيل والتجفيف والتكوير. تمكن مصنع العميل من بدء الإنتاج بعد فترة وجيزة من التركيب، وكانت التعليقات إيجابية للغاية.

الخاتمة: قم ببناء مصنع إعادة تدوير البلاستيك الخاص بك اليوم

فهم كيفية عمل مصانع إعادة تدوير البلاستيك هو الخطوة الأولى نحو بناء عمل تجاري مستدام ومربح في مجال إعادة التدوير. مع العملية والمعدات المناسبة، يمكنك تحويل النفايات البلاستيكية إلى موارد قيمة والمساهمة في كوكب أكثر خضرة.