آلة تكوير الفيلم البلاستيكي هي نوع من معدات إعادة تدوير البلاستيك، والتي تحول البلاستيك إلى مواد حبيبية عن طريق تسخينها، ضغطها، وبثقها.

آلة التحبيب البلاستيكية مناسبة لجميع أنواع المواد الخام البلاستيكية، بما في ذلك PP، PE، HDPE، LDPE، PVC، PS، إلخ. المنتج النهائي هو الكريات البلاستيكية المعاد تدويرها.

تتميز آلة إعادة تدوير أفلام البلاستيك من شولي بمدى إنتاج واسع، من 150 كجم/ساعة إلى 1000 كجم/ساعة.

مقدمة عن آلة إعادة تدوير أفلام البلاستيك

تتميز آلة تكوير الأفلام البلاستيكية من شولي بتصميم برغي مزدوج خاص، مناسب لإنتاج الكريات من PP و PE و ABS و PVC و PC و PET وغيرها من البلاستيك من خلال إعادة التدوير.

تم تقوية المسمار والبرميل خصيصًا لتوفير مقاومة التآكل وأداء الخلط الجيد والإنتاج العالي.

فيديو عمل خط إعادة تدوير أفلام البلاستيك PE PP

كيف يتحول البلاستيك إلى كريات بلاستيكية من خلال آلة إعادة تدوير الأكياس المنسوجة؟

آلة تحبيب أفلام البلاستيك هي معدات تستخدم لمعالجة نفايات البلاستيك أو المواد الخام إلى حبيبات. فيما يلي العملية الأساسية التي يتم من خلالها معالجة البلاستيك إلى حبيبات بلاستيكية بواسطة آلة تحبيب أفلام البلاستيك.

- التغذية: أولاً، سيتم تغذية النفايات البلاستيكية أو المواد الخام إلى منفذ التغذية لآلة تكوير الفيلم البلاستيكي. يجب تغذية المواد البلاستيكية الناعمة من النوع الفيلمي بمساعدة المغذية التلقائية.

- الذوبان والتلدين: من خلال السخان الكهربائي أو طرق التسخين الأخرى، ستتعرض المادة البلاستيكية الموجودة داخل البرميل لدرجة حرارة عالية، وتلين وتذوب تدريجيًا.

- البثق: بمجرد وصول البلاستيك إلى مستوى كاف من التلدين، يتم دفعه إلى برغي البثق داخل البرميل.

- التبريد والمعالجة: يتم تمرير الكريات البلاستيكية المشكلة حديثًا من خلال نظام تبريد، عادةً ما يكون مائيًا، لتبريد الكريات وعلاجها بسرعة.

- التقطيع: بعد تشكيل الكريات ومعالجتها، يتم تقطيعها بواسطة أ آلة قطع الحبيبات البلاستيكية.

معلمات آلة تكوير أفلام البلاستيك

| نموذج | 150 | 180 | 200 | 220 |

| قطر المسمار | 150 ملم | 180 ملم | 200 ملم | 220 ملم |

| سرعة المغزل | 40-50/دقيقة | 40-50/دقيقة | 40-50/دقيقة | 40-50/دقيقة |

| قوة المحرك الرئيسي | 37 كيلو واط | 55 كيلو واط | 75 كيلو واط | 90 كيلو واط |

| المخفض | 250 | 280 | 315 | 330 |

| انتاج | | 300 كجم/ساعة | 350 كجم/ساعة | 380 كجم/ساعة | 420 كجم/ساعة |

يمكن لهذه الأنواع من المخرجات تلبية احتياجات الإنتاج لمعظم الناس. بالطبع، يمكننا أيضًا توفير آلات تكوير الأفلام البلاستيكية بمخرجات أكبر أو أصغر.

إذا كنت بحاجة إلى آلة إعادة تدوير الأفلام البلاستيكية بسعات أخرى، فلا تتردد في ترك معلومات الاتصال الخاصة بك على موقعنا. سنتواصل معك على الفور لتخصيص حل بلاستيكي لك.

حل خط آلة إعادة تدوير أفلام البلاستيك

عادة ما يتم دمج آلة إعادة تدوير أفلام البلاستيك مع كسارة بلاستيك نفايات، وآلة غسيل بلاستيك، وخزان تبريد، وآلة تقريش لتشكيل خط إنتاج لمعالجة مواد الأفلام النفايات.

خط إعادة تدوير أفلام التمدد، الذي يجمع بين آلات إعادة التدوير، والمجارف، والغسالات، وخزانات التبريد، وآلة القطع، يحقق كفاءة معالجة أعلى بنسبة 300% مقارنة بالمعدات المستقلة. على سبيل المثال، يقلل القطع الآلي من وقت المعالجة اليدوية بنسبة 70%، بينما تقضي دورات الغسيل المستمر - البثق - التشكيل على فترات توقف المواد. يتيح هذا التدفق المبسط للعمل خطوط الصناعة لتحويل طن واحد من أفلام النفايات إلى كريات قابلة للتسويق في غضون 4 ساعات، وهو أمر حاسم لتلبية الطلبات العالية على إعادة التدوير في قطاعات التجارة الإلكترونية والزراعة.

إذا كنت مهتمًا، فلا تتردد في الاتصال بنا. سنوصي بأفضل حل لتكوير البلاستيك يناسبك! لا تتردد في الاتصال بنا!

3 أنواع من رؤوس القوالب لمكائن تكوير البلاستيك

هناك ثلاثة أنواع شائعة من رؤوس قوالب التكوير البلاستيكية: رؤوس قوالب التروس الكهربائية، ورؤوس قوالب القوالب الهيدروليكية، ورؤوس قوالب مرشح الخبث الأوتوماتيكي.

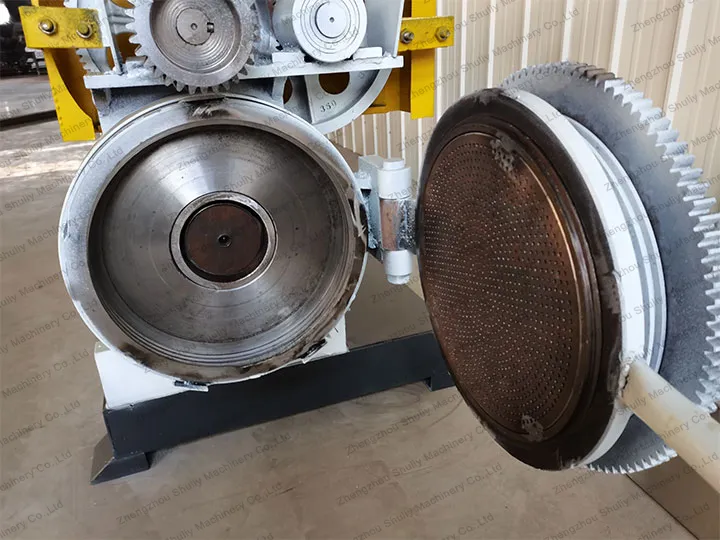

رأس القالب للعتاد الكهربائي

رأس القالب الكهربائي هو نوع من رؤوس القوالب المستخدمة عادة في آلات تكوير البلاستيك. ينقل الطاقة الدورانية إلى اللولب باستخدام نظام نقل تروس مدفوع بمحرك كهربائي، مما يدفع المادة البلاستيكية إلى لولب البثق لعملية البلاستنة والبثق.

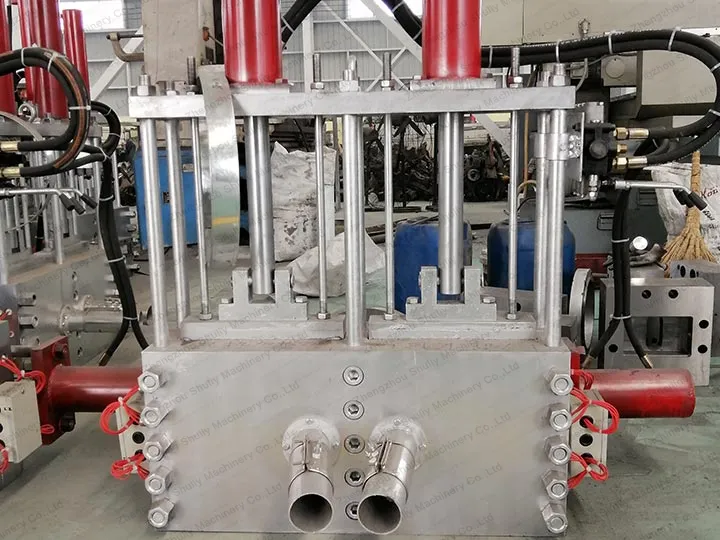

رأس القالب الهيدروليكي

رأس القالب الهيدروليكي في خط تشكيل الحبيبات البلاستيكية يحقق عملية تشكيل البلاستيك والبثق عن طريق دفع المادة البلاستيكية إلى برغي البثق بالقوة التي يوفرها النظام الهيدروليكي.

هذا النوع من رؤوس القالب مناسب للتعامل مع المواد البلاستيكية عالية اللزوجة والصلابة مع قدرة قوية على التكيف والثبات.

رأس القالب لمرشح الخبث الأوتوماتيكي

رأس القالب الأوتوماتيكي لمرشح الخبث هو رأس قالب مصمم خصيصًا لحبيبات الأفلام البلاستيكية. من خلال الهيكل الخاص للبرغي ومنفذ تفريغ الخبث، يتم تفريغ المواد البلاستيكية البلاستيكية من رأس القالب دون الحاجة إلى مصفاة إضافية.

رأس القالب لفلتر الخبث الأوتوماتيكي يتجنب بشكل فعال انسداد الشبكة، مما قد يؤثر على كفاءة الإنتاج، ويبسّط عملية التنظيف والصيانة.

المواد الخام لآلة تكوير أفلام البلاستيك

يمكن لآلات تحبيب الأفلام البلاستيكية من Shuliy معالجة أنواع مختلفة من البلاستيك مثل الأفلام البلاستيكية، والأفلام الزراعية، والأكياس المنسوجة، وزجاجات HDPE، وأكياس الرافي، وما إلى ذلك. محببات الأفلام البلاستيكية.

نحن هنا ندرج فقط بعض المواد الخام. إذا لم تكن متأكدًا من آلة التحبيب البلاستيكية المناسبة لموادك الخام، فلا تتردد في الاتصال بنا للاستفسار.

سعر آلة تشكيل حبيبات البلاستيك

تتراوح أسعار آلة تحبيب الأفلام البلاستيكية Shuliy من بضعة آلاف من الدولارات إلى عشرات الآلاف من الدولارات. تختلف الأسعار باختلاف نماذج ومخرجات المحبب. يرجى التواصل معنا عبر الواتساب أو مراسلتنا مباشرة على الموقع للحصول على عرض أسعار محدد.

ميزات مكائن تشكيل حبيبات البلاستيك لدينا

- التخصيص: تقدم الآلة مجموعة واسعة من النماذج والمواصفات بسعة إنتاج تتراوح بين 300-420 كجم/ساعة، والتي يمكن تخصيصها وفقًا لمتطلبات المستخدمين.

- أجزاء مقاومة للاهتراء معززة: يتم معالجة البرغي والأسطوانة بعلاج تقوية خاص لمقاومة التآكل وضمان إنتاج عالي الحمل على المدى الطويل.

- تصميم توزيع الطاقة الآمن: يضمن نظام توزيع الطاقة التلقائي المنفصل التشغيل الآمن للمحرك ويقلل من خطر الفشل.

احتياطات لآلة تشكيل حبيبات الفيلم البلاستيكي

- يجب استبدال زيت التروس في الآلة الجديدة الخاصة بآلة تكوير أفلام البلاستيك على الأقل مرة واحدة كل ستة أشهر، ويجب تزييت الأجزاء النشطة على الأقل مرة واحدة في الأسبوع.

- يجب أن تصل درجة حرارة المحبب البلاستيكي إلى درجة الحرارة المحددة قبل صب مادة التنظيف أو المادة الخام لتنظيف البقايا الموجودة في المسمار حتى يتم بثق المادة الجديدة، ثم قم بتعليق البثق وتثبيت لوحة المرشح ورأس القالب بسرعة في مكانه

- بعد إغلاق رأس القالب، قم بتشغيل المحرك اللولبي الرئيسي لآلة التكوير البلاستيكية، ويكون المشغل بعيدًا عن رأس القالب في هذا الوقت لمنع رأس القالب من الانسداد بواسطة المواد الصلبة والانفجار وإصابة الأشخاص.

حالات ناجحة من آلة إعادة تدوير الأفلام الزراعية

نحن فخورون بالإعلان عن تصدير آلة إعادة تدوير أفلام البلاستيك لدينا بنجاح إلى العديد من البلدان مثل موزمبيق، والمملكة العربية السعودية، وساحل العاج، وما إلى ذلك. لقد قدمنا أعمال التحبيب لهذه العملاء في حالاتنا السابقة. لقد حقق هؤلاء العملاء أرباحًا كبيرة من خلال استخدام محببات الأفلام البلاستيكية لدينا.

ماكينة صنع الحبيبات البلاستيكية جاهزة للشحن

الأسئلة الشائعة حول آلة تشكيل حبيبات الفيلم البلاستيكي

ما الذي يسبب التصاق الجسيمات بعد التبريد؟

الأسباب: تبريد غير كافٍ أو سرعة تكوير غير متطابقة.

الحلول: زيادة تدفق الهواء/الماء للتبريد، إضافة مواد مضادة للالتصاق (مثل بودرة التلك)، وتنسيق سرعات التكوير والبثق لمنع تراكم الانصهار.

كيفية استكشاف الأخطاء وإصلاحها عند حدوث ضوضاء غير طبيعية أثناء تشغيل المعدات؟

إذا حدث صوت غير عادي في المسمار أو علبة التروس، تحقق من الفجوة بين المسمار والأسطوانة بحثًا عن أجسام معدنية غريبة، واستبدل زيت علبة التروس، وافحص تآكل المحامل، واضبط التركيز في نظام النقل لتقليل الاهتزاز.