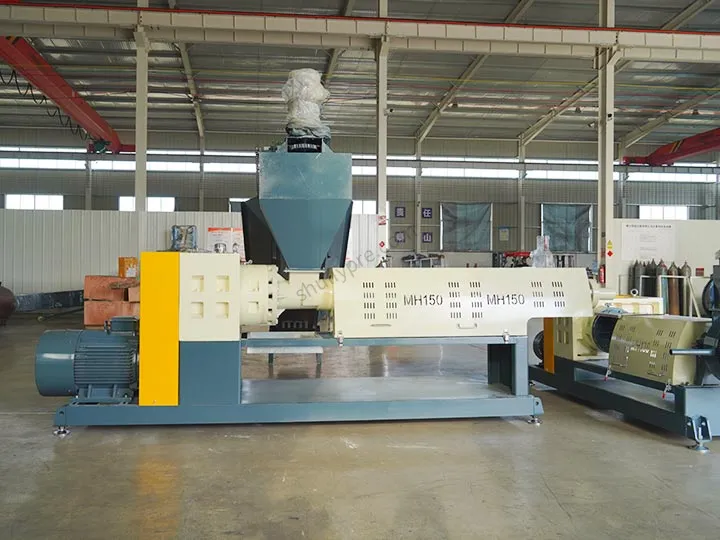

La máquina granuladora de bolsas tejidas Shuliy, también conocida como máquina granuladora de PP, es un tipo de equipo especializado en convertir bolsas tejidas de desecho en bolitas de plástico. Los granuladores de bolsas tejidas se pueden utilizar para reciclar bolsas de plástico desechadas, como bolsas de piel de serpiente, bolsas de gran tonelaje, bolsas de rafia PP, bolsas de cemento, etc.

Introducción de la máquina de peletizado de plástico

La máquina granuladora de bolsas tejidas es un equipo especializado para peletizar bolsas tejidas, bolsas de rafia y bolsas de cemento.

Después de que las piezas son trituradas, la máquina calienta y plastifica estos materiales de bolsas de plástico, y luego los extruye y corta en pellets uniformes a través del dado.

Estos gránulos se pueden utilizar en industrias como el embalaje, la artesanía y los materiales biodegradables. Ayuda a convertir los desechos plásticos en recursos valiosos, promoviendo la utilización sostenible de los materiales naturales.

Video de la máquina granulatora de reciclaje

Este video trata sobre una máquina de gránulos de plástico en acción, mostrando cómo se procesa la bolsa tejida en pellets de plástico.

Principio de funcionamiento de la máquina granulatora de bolsas tejidas

El principio de funcionamiento de la máquina granuladora de bolsas tejidas incluye principalmente los pasos de trituración, fusión, extrusión y granulación de bolsas tejidas.

En primer lugar, las bolsas tejidas de desecho se introducen en la trituradora, que las tritura en trozos pequeños.

Luego, estos fragmentos se introducen en la máquina de granulación de bolsas tejidas, que convierte los residuos de bolsas tejidas en un estado fundido a través del proceso de calentamiento y fusión.

Finalmente, el plástico fundido se extruye a través de la forma de la matriz o la salida del extrusor de la máquina recicladora de bolsas tejidas y se le da forma de material granular después del enfriamiento.

Muestra de materias primas recicladas de bolsas tejidas

La máquina granuladora de bolsas tejidas se utiliza para bolsas tejidas de PP, PE, bolsas de rafia, bolsas jumbo, bolsas de plástico, bolsas de cemento, bolsas de serpiente, etc.

Proceso de trabajo de la máquina de peletizado de PP

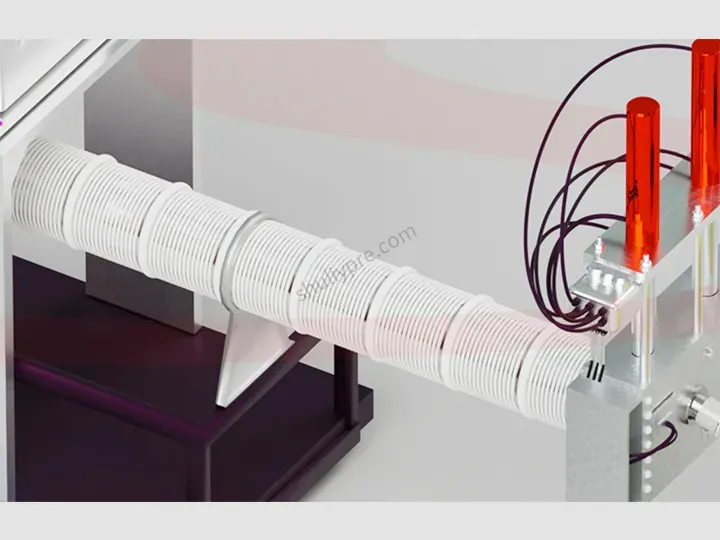

Alimentación: el tornillo en el transportador de alimentación envía piezas de plástico a granular de manera continua y uniforme, lo que asegura la estabilidad en la descarga. Además, la máquina reemplaza la operación manual y mejora la producción.

Calentamiento: El calentamiento electromagnético de esta máquina granuladora de reciclaje derrite las piezas de desecho en una pasta.

Extrusión: Este dado hidráulico automático extruye la pasta en tiras para un corte posterior.

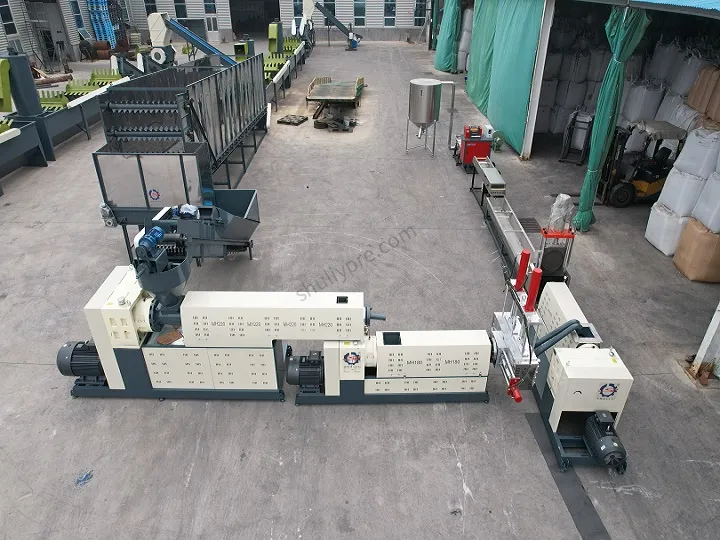

Recomendaciones de configuración de la máquina peletizadora de bolsas tejidas

Seleccionar la máquina granuladora de bolsas tejidas adecuada requiere considerar el grado de limpieza de la bolsa tejida y el efecto de granulación deseado. La limpieza de la materia prima puede influir en la elección del tipo y configuración de la máquina granuladora de bolsas tejidas. A continuación se ofrecen algunas sugerencias para seleccionar la máquina granuladora de bolsas tejidas adecuada.

Aplastante

Si la bolsa tejida contiene más impurezas o contaminantes, se recomienda elegir una máquina granuladora de bolsas tejidas con un sistema de trituración potente. Se recomienda un triturador de plástico de doble eje para que las bolsas tejidas no se enreden en el eje de la máquina trituradora de plástico. Además, los plásticos suaves como las bolsas tejidas generalmente se seleccionan con un alimentador automático, una máquina pelletizadora de bolsas tejidas.

Lavado

La limpieza de las bolsas tejidas se puede clasificar en dos situaciones: bolsas tejidas limpias y bolsas tejidas con contaminantes. Las bolsas tejidas limpias suelen estar libres de contaminantes y objetos extraños evidentes, mientras que las bolsas tejidas con contaminantes pueden contener impurezas, aceite, etc. Se recomienda a los fabricantes con altos requisitos de calidad para los productos terminados que configuren una máquina de lavado de plástico. La limpieza de la materia prima tiene un mayor impacto en los pellets de plástico.

Además, Shuliy puede personalizar diferentes soluciones de reciclaje según diversos requisitos y satisfacer necesidades personalizadas.

La máquina granuladora de bolsas tejidas es la parte principal de la línea de producción de reciclaje de plástico. Si se utiliza junto con otras máquinas para formar una línea de granulacion de reciclaje de plástico completa, se puede maximizar la tasa de utilización del equipo.

Si tiene alguna necesidad al respecto, no dude en contactarnos.

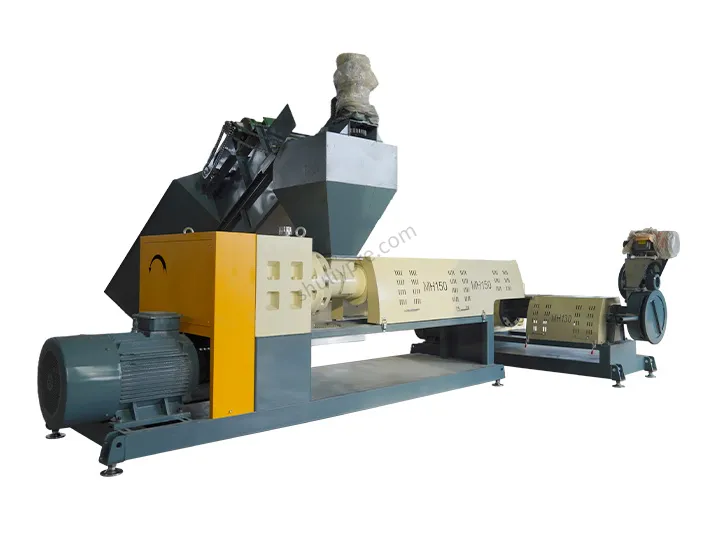

Ventajas de la máquina de granulación de reciclaje de PP

Eficiente y ahorradora de tiempo: La cabeza de dado hidráulica de esta máquina no necesita detenerse para cambiar, lo que ahorra más tiempo en comparación con la tradicional cabeza mágica de engranaje.

Ahorro de energía y durabilidad: El dispositivo de calentamiento adopta calentamiento electromagnético en lugar del método tradicional de calentamiento con placas de cerámica, lo que no solo ahorra energía, sino que también tiene una vida útil más larga.

Casos globales de la máquina de granulación de reciclaje

Máquina granuladora de bolsas tejidas Shuliy a la venta para Arabia Saudita, y nuestros ingenieros irán al sitio para ayudar a los clientes a instalar.

Preguntas frecuentes sobre la máquina de granulación de bolsas tejidas

¿Cuál es el producto final de esta línea y en qué campos se puede utilizar este producto?

El producto final son pellets de plástico. Estos gránulos tienen amplias aplicaciones en múltiples campos. Por ejemplo, en la industria del embalaje, los gránulos se utilizan para producir películas de plástico y bolsas de rafia; en la agricultura, para fabricar películas agrícolas y tuberías; en utilidades diarias para procesar juguetes y muebles.

¿Cuáles son las formas de reciclar bolsas tejidas de desecho?

Si deseas iniciar un negocio de peletización a partir de bolsas tejidas de desecho, puedes considerar las siguientes formas de encontrar bolsas tejidas de desecho:

Estaciones de reciclaje de desechos y puntos de recolección de basura: Trabaje con sus estaciones locales de reciclaje de desechos, puntos de recolección de basura o centros de disposición de basura para obtener bolsas tejidas de desecho.

Supermercados y minoristas: Trabaje con supermercados, centros comerciales o minoristas que generalmente tienen grandes cantidades de bolsas tejidas de desecho.

Sitios de construcción y áreas industriales: Los sitios de construcción y las áreas industriales a menudo utilizan bolsas tejidas para transportar materiales de construcción o artículos.

¿Se pueden personalizar las partes de esta máquina?

Las partes de la máquina granuladora de bolsas tejidas se pueden personalizar, como el tamaño del pelletizador, los pellets, las franjas y el molde hidráulico automático, así como la longitud del tornillo en el transportador de alimentación.

Si deseas conocer más detalles u otra información, no dudes en contactarnos para que puedas obtener tus soluciones personalizadas.