प्लास्टिक बोतल रिसाइक्लिंग लाइन एक पूर्ण सेट उपकरण है जो废弃 प्लास्टिक बोतलों को उच्च गुणवत्ता वाले PET बोतल चिप्स में परिवर्तित करने के लिए है, जो废弃 प्लास्टिक बोतलों के रिसाइक्लिंग को प्रभावी ढंग से साकार कर सकता है।

शुली मशीनरी प्लास्टिक रिसाइक्लिंग मशीनरी का एक पेशेवर आपूर्तिकर्ता है, और हम इसे आपकी आवश्यकताओं के अनुसार अनुकूलित कर सकते हैं। हमसे संपर्क करने के लिए आपका स्वागत है।

पीईटी बोतल रीसाइक्लिंग लाइन का परिचय

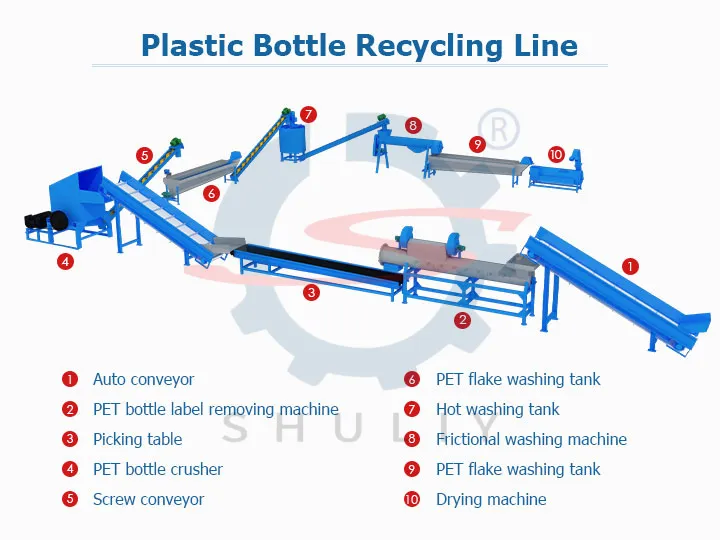

हमारी PET बोतल रीसाइक्लिंग लाइन कचरे की प्लास्टिक बोतलों को एक लेबल हटाने की मशीन, एक क्रशर, एक गर्म धोने के टैंक, एक घर्षण धोने के टैंक और एक सुखाने की मशीन के माध्यम से PET फ्लेक्स में परिवर्तित करती है। यह लाइन प्लास्टिक कचरे को कम करके और संसाधनों को बचाकर पर्यावरणीय स्थिरता को बढ़ावा देने में एक महत्वपूर्ण भूमिका निभाती है।

शुली मशीनरी के पास पीईटी बोतल को कुचलने और धोने की विभिन्न प्रकार की मशीनें हैं, और पूरी लाइन को अनुकूलित किया जा सकता है। हमारे कारखाने में आने के लिए आपका स्वागत है।

प्लास्टिक बोतल रीसाइक्लिंग मशीन का कार्य वीडियो

यह वीडियो इस PET बोतल रिसाइक्लिंग लाइन के क्रियान्वयन के बारे में है, जो दिखाता है कि कचरे की बोतलों को प्लास्टिक के चिप्स में कैसे संसाधित किया जाता है।

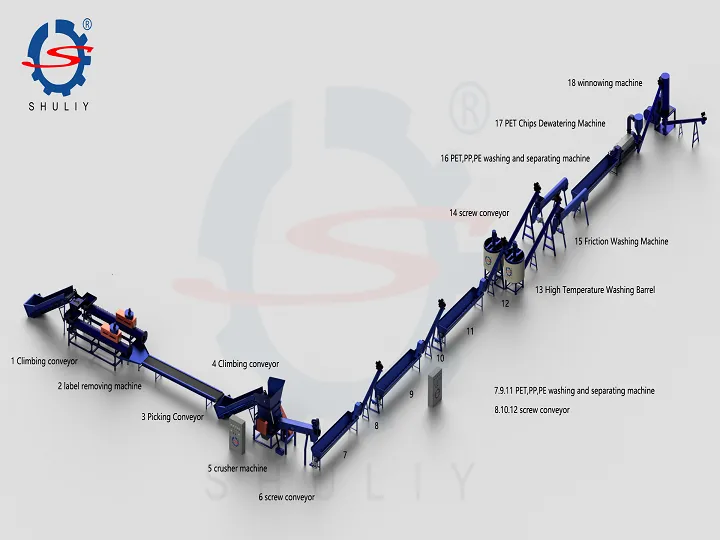

प्लास्टिक बोतल रीसाइक्लिंग लाइन की प्रक्रिया प्रवाह

लेबल हटाना – कुचलना – बोतल के ढक्कन को अलग करना – धोना – सुखाना – भंडारण

- सबसे पहले, यदि कच्चा माल बोतल पैकेज के रूप में पैक किया गया है, तो एक प्लास्टिक बैलर बोतलों को अलग करेगा और फिर उन्हें बेल्ट कन्वेयर के माध्यम से प्लास्टिक बोतल लेबल हटाने की मशीन में भेज देगा।.

- दूसरे, PET बोतल पुनर्चक्रण लाइन में मैनुअल चयन एक महत्वपूर्ण कदम है, जो अन्य रंग की बोतलों और लेबल वाली बोतलों का चयन करने के लिए है ताकि तैयार उत्पाद की शुद्धता बनी रहे।

- इसके बाद, क्रशर इन PET बोतलों को चूरा में काट देगा, और फिर इन्हें अशुद्धियों और ढक्कनों को हटाने के लिए PET चूरा धोने के टैंक में भेजा जाएगा।

- अगला, गर्म पानी का टैंक और घर्षण धोने का टैंक चिप्स को और साफ करने के लिए हैं।

- यदि आपके पास अंतिम उत्पाद की गुणवत्ता के लिए उच्चतर आवश्यकताएँ हैं, तो आप इन धोने के टैंकों की मात्रा तय कर सकते हैं।

- प्लास्टिक बोतल रिसाइक्लिंग लाइन का अंतिम चरण यह है कि सुखाने की मशीन इन PET चिप्स से पानी निकालती है।

प्लास्टिक बोतल रिसाइक्लिंग मशीन का लाइव संचालन वीडियो

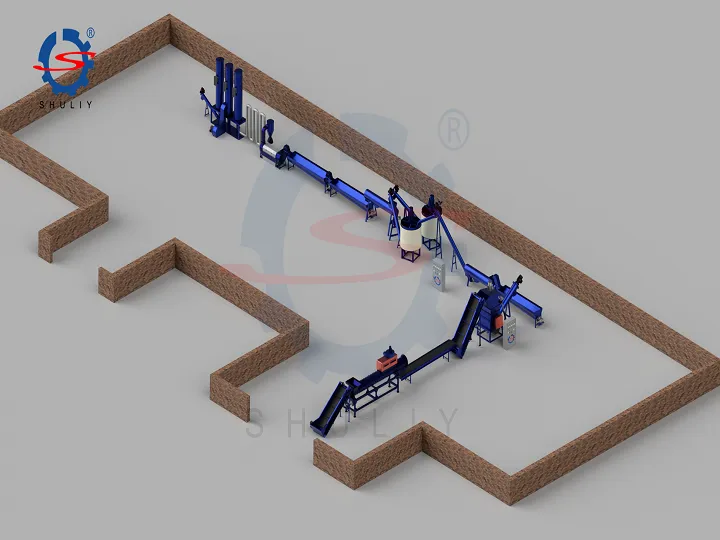

पीईटी बोतल क्रशिंग वॉशिंग मशीन को आपके बजट और पौधे के आकार के अनुरूप अनुकूलित किया जा सकता है, इसलिए बेझिझक हमसे संपर्क करें। हम आपके लिए सही प्लास्टिक बोतल रीसाइक्लिंग लाइन की सिफारिश कर सकते हैं।

rPET फ्लेक्स उत्पादन लाइन के कच्चे माल और तैयार उत्पाद

कच्चे माल

rPET फ्लेक्स उत्पादन लाइन के मुख्य कच्चे माल में प्रयुक्त PET बोतलें शामिल हैं, जो आमतौर पर संकुचित बाले में खरीदी जाती हैं। ये बोतलें विभिन्न स्रोतों से आती हैं, जिनमें पेय कंटेनर, मिनरल वाटर बोतलें, कार्बोनेटेड ड्रिंक बोतलें, खाना पकाने का तेल की बोतलें, मसाले की बोतलें, और अन्य PET से बने कचरे के पैकेजिंग कंटेनर शामिल हैं। इनमें अक्सर लेबल, कैप्स रहते हैं, और इनमें अवशेष तरल या दाग हो सकते हैं।

ऊपर दिए गए सामग्री सभी कच्चे माल नहीं हैं जो PET बोतल पुनर्चक्रण संयंत्र में उपयोग किए जा सकते हैं। यदि आप उन सामग्रियों के बारे में पूछताछ करना चाहते हैं जो आपके पास हैं, तो आप हमें एक संदेश छोड़ सकते हैं।

तैयार उत्पाद

PET बोतल पुनर्चक्रण लाइन का प्राथमिक तैयार उत्पाद PET फ्लेक्स है, जो पुनर्नवीनीकरण PET उत्पादों के लिए एक प्रमुख कच्चा माल के रूप में कार्य करता है। इन फ्लेक्स का उपयोग सीधे कपड़ों, कालीनों और पैडिंग सामग्रियों जैसे वस्त्रों के लिए पॉलिएस्टर स्टेपल फाइबर बनाने में किया जा सकता है। ये पैकेजिंग बॉक्स और ब्लिस्टर उत्पादों के लिए PET शीट बनाने की भी अनुमति देते हैं, और नए PET बोतलों में फिर से उड़ाने के लिए पुनः उपयोग किया जा सकता है ताकि पेय पैकेजिंग का चक्रीय पुनः उपयोग किया जा सके।

प्लास्टिक बोतल पुनर्चक्रण लाइन के मुख्य मशीनें

पीईटी बोतल के लिए प्लास्टिक बेल ओपनर

उपयोग की गई PET बोतलों के कसकर दबाए गए बंडलों को अनपैक और ढीला करें।

यह मशीन घूर्णन करने वाले ब्लेड का उपयोग करके बाले की पट्टियों को तोड़ती है और बंडल की गई बोतलों को अलग करती है, उन्हें बाद की प्रक्रिया के लिए ढीले व्यक्तियों में परिवर्तित करती है।

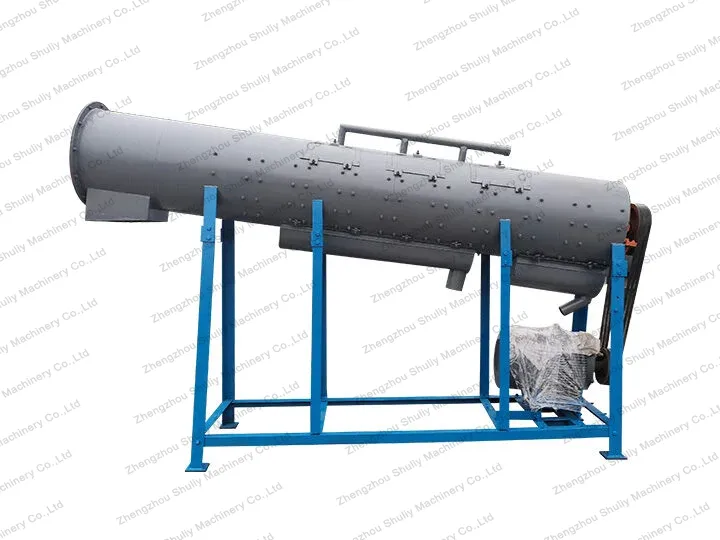

पीईटी बोतल पुनर्चक्रण के लिए टम्बलर स्क्रीन

PET बोतल रिसाइक्लिंग लाइन के लिए टम्बलर स्क्रीन PET बोतल के टुकड़ों से बारीक अशुद्धियों को छानने के लिए काम करती है।

यह कुचले हुए PET फ्लेक्स से रेत, कागज के टुकड़े और ढक्कन के मलबे जैसे छोटे प्रदूषकों को अलग करने के लिए जालीदार स्क्रीन के साथ एक घूर्णन ड्रम का उपयोग करती है।

प्लास्टिक बोतल लेबल हटाने की मशीन

यह मशीन आमतौर पर एक समायोज्य ब्लेड डिवाइस से सुसज्जित होती है और विभिन्न बोतल प्रकारों, जैसे कि मिनरल वॉटर की बोतलें और पेय की बोतलें, के साथ-साथ विभिन्न सामग्रियों, जैसे कि कागज के लेबल और पीवीसी/पीई फिल्म लेबल, को संभाल सकती है।

PET बोतल धोने की लाइन में मशीन स्थिरता से काम करती है और इसका डि-लेबलिंग दर 98% है, जिससे श्रम की बचत होती है।

PET बोतल क्रशिंग मशीन

इस प्रणाली को पुनर्चक्रित प्लास्टिक की बोतलों को छोटे टुकड़ों में कुचलने के लिए डिज़ाइन किया गया है। पीईटी बोतल क्रशर प्लास्टिक बोतल रीसाइक्लिंग लाइन में उपकरण का एक महत्वपूर्ण हिस्सा है।

पीपी पीई अलग करने वाला टैंक

पीईटी फ्लेक्स से पीपी या पीई बोतल के ढक्कन को अलग करने के लिए उपयोग किया जाता है। इस प्रक्रिया के परिणामस्वरूप बाद में पुनर्चक्रण के लिए शुद्ध पीईटी बोतल के टुकड़े प्राप्त होते हैं।

गर्म धोने का टैंक

यह उच्च तापमान वाले पानी में गर्म धोने के लिए औद्योगिक क्षार को जोड़कर प्राप्त किया जाता है, इस प्रकार पीईटी बोतल के गुच्छे की सतह से ग्रीस हटा दिया जाता है और उन्हें साफ और अधिक पारदर्शी बना दिया जाता है।

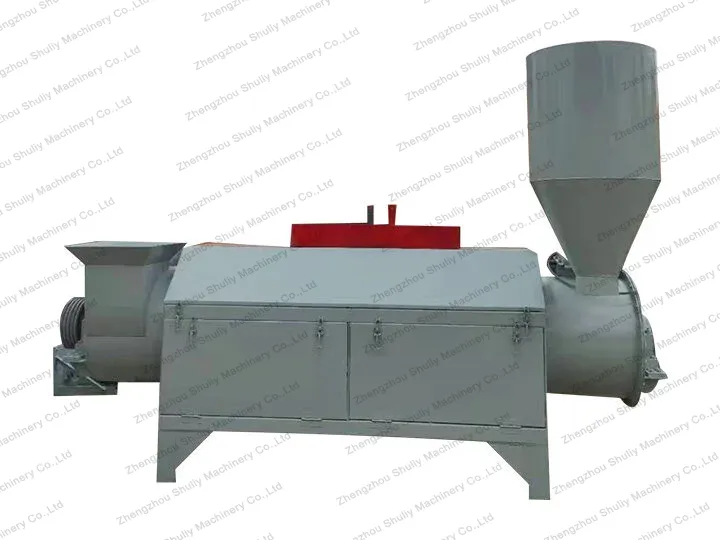

घर्षण धोने की मशीन

बोतल की सतह पर किसी भी अवशिष्ट गंदगी, कांच, धातु, कागज की धूल या इसी तरह की अन्य चीजों को हटाने के लिए बोतलों को रगड़ा और साफ किया जाता है।

पीईटी बोतल धोने की मशीन

एक मल्टी-स्टेज ठंडे पानी का कुल्ला बोतल के गुच्छे की सतह से औद्योगिक क्षारीय पानी और अशुद्धियों को हटा देता है, जिससे वे स्वच्छ और अधिक संदूषण-मुक्त हो जाते हैं।

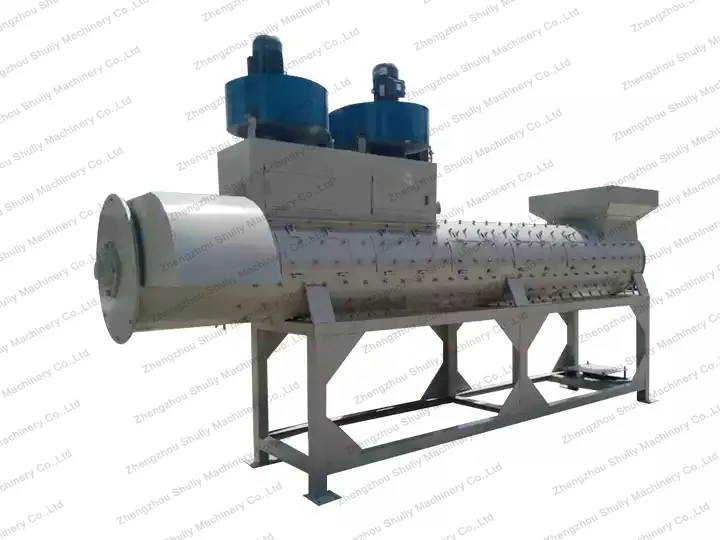

प्लास्टिक ड्रायर मशीन

मशीन के हाई-स्पीड रोटेशन से बोतल के गुच्छे से पानी निकल जाता है, जिसके परिणामस्वरूप सूखे और साफ गुच्छे बनते हैं जिन्हें सीधे बैग में संग्रहित किया जा सकता है।

अंतिम PET बोतल धोने की लाइन को गुणवत्ता आवश्यकताओं के अनुसार लचीले ढंग से समायोजित किया जा सकता है, इसलिए कृपया अपनी विचारों और आवश्यकताओं के साथ हमसे संपर्क करने में संकोच न करें ताकि हम आपकी PET बोतल पुनर्चक्रण संयंत्र के लिए लाभकारी पुनर्चक्रण लाइन का डिज़ाइन कर सकें।

पीईटी बोतल पुनर्चक्रण मशीन पैरामीटर

| आइटम | विवरण |

| पीईटी बोतल पुनर्चक्रण के लिए टम्बलर स्क्रीन | लंबाई: 4.5 मीटर चौड़ाई: 1.5 मीटर मोटर पावर: 7.5 किलowatt बाहरी दीवार की मोटाई: 8 मिमी ब्लेड: 10 मिमी |

| पीईटी बोतल के लिए प्लास्टिक बेल ओपनर | लंबाई: 4.0 मीटर चौड़ाई: 1.5 मीटर ऊँचाई: 2.8 मीटर मोटर पावर: 7.5 + 2.2 किलोवाट |

| प्लास्टिक बोतल लेबल हटाने की मशीन | मॉडल: एसएल-600 पावर: 11KW+3KW क्षमता: 1-1.2t/h आकार: 4000*1800*1600मिमी वजन: 1500 किलो |

ऊपर दिए गए पैरामीटर केवल उदाहरण के लिए हैं, हम मशीनों के विभिन्न आकार प्रदान करते हैं। यदि आप अधिक विस्तृत जानकारी जानना चाहते हैं, तो कृपया हमारी वेबसाइट पर एक संदेश छोड़ें, और हम समय पर आपसे संपर्क करेंगे।

प्लास्टिक बोतल रीसाइक्लिंग लाइन के लाभ

- स्वचालन और निरंतर संचालन: बोतल पैकेज के असेंबली से लेबल हटाने, कुचलने, धोने और सुखाने तक, पूरा प्रक्रिया कन्वेयर बेल्ट और अन्य उपकरणों द्वारा जोड़ी जाती है ताकि मैनुअल हस्तक्षेप को न्यूनतम किया जा सके और प्रसंस्करण दक्षता को बढ़ाया जा सके।

- उच्च गुणवत्ता वाला उत्पाद: लेबल हटाने की मशीन मैनुअल रंग चयन के साथ संयोजित, प्रभावी रूप से लेबल अवशेष और विदेशी रंग की बोतलों को समाप्त करती है, और समाप्त उत्पादों की शुद्धता सुनिश्चित करने के लिए कई सफाई प्रक्रियाओं के साथ।

- अनुकूलन और लचीलापन: PET बोतल धोने की लाइन में सफाई टैंकों की संख्या को विभिन्न शुद्धता आवश्यकताओं के लिए स्वतंत्र रूप से बढ़ाया या घटाया जा सकता है। मशीन का रंग भी ग्राहक की आवश्यकताओं के अनुसार अनुकूलित किया जा सकता है।

PET बोतल धोने की लाइन के सामान्य प्रश्न

क्या PET बोतल धोने का संयंत्र व्यवसाय लाभदायक है?

आंकड़ों के अनुसार, प्लास्टिक की बोतलें एक साधारण प्रक्रिया के बाद $200 से अधिक की कीमत पर $500 प्रति टन से अधिक में बेची जा सकती हैं। इसलिए, प्लास्टिक बोतल रीसाइक्लिंग व्यवसाय बहुत लाभदायक है।

शुली मशीनरी के पास एक पूर्ण PET बोतल धोने का संयंत्र है जो आपको अपना व्यवसाय शुरू करने में मदद करेगा। निवेश बहुत बड़ा नहीं है। संचालन अपेक्षाकृत सरल है, और जब सामग्री प्रचुर मात्रा में होती है तो लाभ काफी होता है।

पीईटी बोतल क्रशिंग वाशिंग मशीन का आउटपुट

हम 500 किग्रा/घंटा से 3000 किग्रा/घंटा तक के आउटपुट वाली पीईटी बोतल क्रशिंग वॉशिंग मशीन की आपूर्ति कर सकते हैं।

बड़ी या छोटी क्षमता वाली प्लास्टिक बोतल रीसाइक्लिंग लाइनों के लिए, कृपया अनुकूलन के लिए हमसे संपर्क करें।

मुझे rPET फ्लेक्स उत्पादन लाइन संचालित करने के लिए कितने कर्मचारियों की आवश्यकता है, और किस स्तर का कौशल आवश्यक है?

श्रम एक मुख्य परिचालन लागत है। एक मानक 1,000 किग्रा/घंटा rPET फ्लेक्स उत्पादन लाइन के लिए, आपको आमतौर पर 3-5 कर्मचारी चाहिए होंगे: एक सामग्री खिलाने के लिए, 2-3 मैनुअल सॉर्टिंग के लिए, और एक बैक-एंड और पैकिंग की निगरानी के लिए। नियंत्रण प्रणाली केंद्रीकृत और उपयोगकर्ता के अनुकूल है। हमारे इंजीनियर 1-2 दिनों का ऑन-साइट, व्यावहारिक प्रशिक्षण प्रदान करते हैं, जिससे आपकी टीम पूरी rPET फ्लेक्स उत्पादन लाइन को कुशलतापूर्वक संचालित कर सके।

मुख्य पहनने वाले भाग कौन से हैं, उनका जीवनकाल क्या है, और क्या उन्हें आसान और सस्ती तरीके से बदला जा सकता है?

प्राथमिक पहनने वाले भाग क्रशर ब्लेड और लेबल रिमूवर चाकू हैं। उनका जीवनकाल आपके इनपुट सामग्री की सफाई पर निर्भर करता है, लेकिन आमतौर पर यह कई महीनों तक चलता है। हमारा क्रशर तेज़ ब्लेड परिवर्तन के लिए डिज़ाइन किया गया है, और हम एक पेशेवर चाकू शार्पनिंग मशीन भी प्रदान कर सकते हैं ताकि आप उन्हें स्वयं ही फिर से तेज कर सकें, जिससे प्रतिस्थापन लागत में भारी कमी आएगी। हम सभी मूल स्पेयर पार्ट्स की दीर्घकालिक आपूर्ति उचित कीमतों पर करने की गारंटी देते हैं।

ऑर्डर देने से लेकर मेरी फैक्ट्री में प्लांट के संचालन तक कुल लीड टाइम क्या है?

कुल परियोजना समयरेखा तीन मुख्य चरणों में विभाजित है:

1. निर्माण: आमतौर पर 45-90 दिन, लाइन की जटिलता पर निर्भर करता है।

2. महासागर माल ढुलाई: आपके भौगोलिक स्थान पर निर्भर करता है।

3. साइट पर स्थापना और कमीशनिंग: आमतौर पर 15-30 दिन लगते हैं।

हम एक विस्तृत परियोजना गैंट चार्ट प्रदान करेंगे ताकि आपके पास हर चरण के लिए एक स्पष्ट समयरेखा हो।

क्या आप स्थापना और प्रशिक्षण प्रदान करते हैं? मेरे कर्मचारी पूर्व अनुभव नहीं रखते।

हाँ, यह हमारी सेवा का एक मुख्य भाग है और एक महत्वपूर्ण लाभ है। हम अनुभवी इंजीनियरों को आपके साइट पर भेजते हैं ताकि PET रीसाइक्लिंग प्लांट की पूरी स्थापना की निगरानी की जा सके, उपकरण का कमीशन किया जा सके, और आपके ऑपरेटरों और मेंटेनेंस स्टाफ के लिए व्यापक, व्यावहारिक प्रशिक्षण प्रदान किया जा सके। हम तब तक जारी रखते हैं जब तक कि PET रीसाइक्लिंग प्लांट सुचारू रूप से चल रहा हो और योग्य उत्पाद बना रहा हो। हम एक पूरी तरह से संचालित प्रणाली प्रदान करते हैं, न कि केवल मशीनों का सेट।

वॉरंटी अवधि क्या है, और यदि मशीन वॉरंटी समाप्त होने के बाद फेल हो जाती है तो क्या होता है?

हम सभी भागों पर निर्माण दोषों के खिलाफ एक साल की मानक वारंटी प्रदान करते हैं, जो अंतिम स्वीकृति की तारीख से प्रभावी है। सबसे महत्वपूर्ण बात यह है कि हम जीवन भर तकनीकी समर्थन भी प्रदान करते हैं। वारंटी अवधि के बाद भी, आप कभी भी वीडियो कॉल के माध्यम से रिमोट ट्रबलशूटिंग के लिए हमसे संपर्क कर सकते हैं। यदि ऑन-साइट सेवा की आवश्यकता हो, तो हम एक इंजीनियर भेज सकते हैं (खर्च पर), और हम सभी स्पेयर पार्ट्स की दीर्घकालिक आपूर्ति की गारंटी देते हैं। हमारा लक्ष्य आपके दीर्घकालिक सफलता में आपका साथी बनना है।