Линия гранулирования переработки пластика в основном используется для переработки отходов пластиковых бочек, пластиковых тазов, пластиковых стульев, пластиковых игрушек и других твердых пластиков. Эта машина для гранулирования переработки пластика объединяет дробление и очистку, сушку, гранулирование и упаковку, и является профессиональным оборудованием для переработки отходов пластика.

Кроме того, фирма Шулий может установить и установить линию по переработке хлопьев PP PE в соответствии с требованиями клиента.

Введение в линию гранулирования переработки пластика

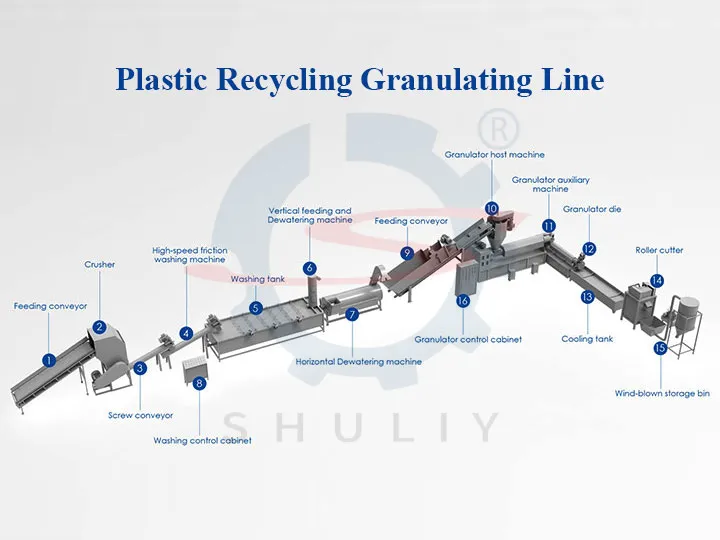

Линия гранулирования переработки пластика в основном состоит из машины для дробления пластика, резервуара для промывания пластика, машины для производства пластиковых гранул, охладительного резервуара и резака для пластиковых гранул. Линия переработки фракций PP и PE обеспечивает высокоавтоматизированное производство, которое может превращать твердые пластики в переработанные пластиковые гранулы и экономить трудозатраты.

Компания Shuliy Machinery более десяти лет сосредоточена на линиях гранулирования переработки пластика и имеет богатый опыт в производстве машин для переработки пластика. Мы будем рады видеть вас в нашем заводе.

Процесс гранулирования пластиковых отходов

Дробление – Очистка – Сушка – Плавление – Экструзия – Грануляция – Резка на гранулы

- Во-первых, твердые пластиковые материалы, такие как пластиковые унитазы, ведра и игрушки, разбиваются на куски и хлопья с помощью машины для измельчения пластика.

- Во-вторых, машина для мойки пластика очистит примеси, такие как пыль и грязь.

- В-третьих, горизонтальная машина для обезвоживания используется для обезвоживания и сушки пластиковых чипсов после очистки.

- Затем хлопья сначала попадают на подающий конвейер, а затем они плавятся с помощью электромагнитного нагрева, чтобы преобразовать куски из твердого состояния в расплавленное.

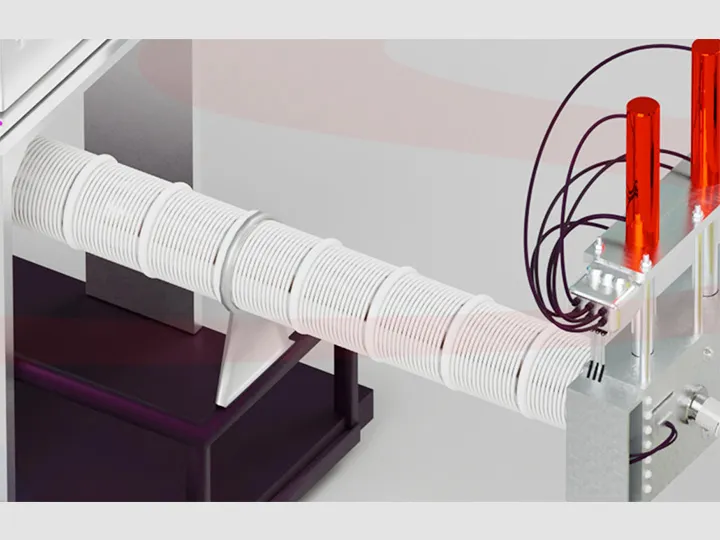

- После этого винт внутри гранулятора для переработки пластика используется для приложения давления к пасте, проталкивая ее через головку матрицы, чтобы экструзировать в полоски.

- Наконец, экструзированный пластик быстро охлаждается и отверждается с помощью устройства охлаждения, такого как охлаждающий водяной бак или система воздушного охлаждения, а затем нарезается на однородные гранулы с помощью устройства гранулирования в соответствии с заданным размером.

Рабочее видео линии гранулирования переработки пластика в действии

Применение машины для гранулирования переработки пластика

Пластиковая линия переработки гранулирования является решением, разработанным для переработки твердых пластиков, таких как пластиковые барабаны, пластиковые горшки, пластиковые стулья, пластиковые палеты, фруктовые корзины, пластиковые контейнеры и т. д. Пластиковая линия переработки гранулирования может прямо превращать твердые пластиковые изделия в переработанные пластиковые гранулы для достижения переработки пластика.

Если ваш сырьевой материал не упоминается выше, или вы хотите подтвердить его пригодность для этой линии гранулирования пластиковых хлопьев из ПП и ПЭ, пожалуйста, не стесняйтесь оставить сообщение через сайт. Мы свяжемся с вами вовремя.

Принцип работы линии гранулирования переработки пластика

Основной принцип термопластического формования линии переработки пластиковых гранул заключается в обратимых физических свойствах нагрева и плавления, а также охлаждения и затвердевания с помощью пластиковых материалов. Когда отходы пластика попадают в гранулятор, система нагрева разогревает их выше точки плавления.

После этого он преобразуется из твердого состояния в вязкую жидкую массу, а затем винт вращается и создает давление, чтобы масса равномерно пластифицировалась и экструзировалась через матрицу.

Наконец, он быстро охлаждается в системе охлаждения и в конечном итоге нарезается на гранулы в соответствии со спецификациями с помощью машины для резки пластиковых полос.

Весь процесс линии гранулирования переработки пластика представляет собой лишь физический фазовый переход без разрушения химической структуры, что позволяет реализовать переработку отходов пластика.

Основная машина завода по переработке пластиковых отходов

Шаг 1: Машина для измельчения пластика

Машина для измельчения пластика может легко измельчать твердые пластиковые материалы в мелкие фракции, тем самым снижая транспортные расходы и облегчая последующую грануляцию пластика.

Шаг 2: Машина для мойки пластика

Пластиковая стиральная машина используется для промывки измельченных материалов с помощью спирального устройства на дне, чтобы удалить осадок и другие примеси, а также дополнительно обеспечить чистоту пластиковых чипсов и улучшить качество переработанных гранул.

Шаг 3: машина для сушки пластика

Горизонтальная машина для отжима

Шаг 4: Шаг 4

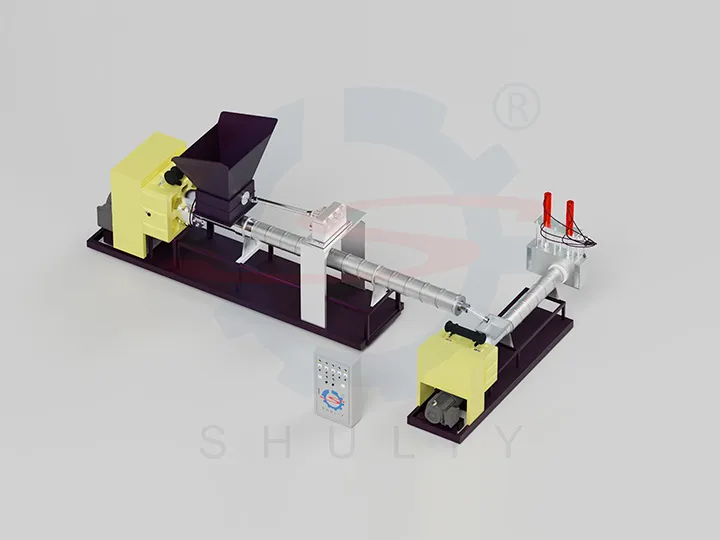

Машина для пеллетизации пластика

Шаг 5: Шаг 5

Машина для резки пластиковых полос нарезает длинные полосы охлажденного пластика на небольшие, равномерные гранулы. Доступны различные модели машин для удовлетворения различных требований к производительности.

Точная конфигурация машины может быть адаптирована под ваши нужды. Вы можете связаться с нами для получения конкретных вопросов о линии гранулирования переработки пластика.

Почему стоит купить нашу машину для гранулирования переработки пластика?

- Пластиковые гранулы, произведенные в машинах для переработки пластиковой пеллетизации, имеют высокое качество, не имеют воздушных пузырей, являются полными и круглыми, а размер и толщина гранул, вырезанных машиной для нарезки пластиковой пеллеты, могут быть отрегулированы.

- Система дробления имеет износостойкий дизайн, чтобы обеспечить долгосрочную, непрерывную и стабильную работу системы.

- Система высокоскоростной центрифугирования с подходящей скоростью вращения для различных материалов, чтобы применить соответствующую силу удара лопастей, хороший эффект очистки.

- Пластиковая гранулирующая машина управляется автоматически и является полностью автоматической линией сборки, которая реализует прямое преобразование отходов пластика в готовые гранулы.

- Что касается винтового барреля, он изготовлен из импортной высокопрочной углеродистой стали, которая обладает особенностью прочности.

- Внешний вид машины красивый и элегантный, и его можно окрасить в соответствии с требованиями клиента.

Часто задаваемые вопросы о линии гранулирования пластиковых чешуек

В чем разница между пластиковыми PP и PE?

Прежде всего, состав этих двух материалов различен; основным компонентом пластиков PP является полипропилен, а основным компонентом пластиков PE является полиэтилен.

Во-вторых, характеристики пластиков PP и PE различаются. Прочность, жесткость и термостойкость пластика PP лучше, чем у PE, и его можно использовать при температуре около 100 ℃. Он обладает хорошими диэлектрическими свойствами и высокой частотной изоляцией, не подвержен воздействию влаги, но при низких температурах становится хрупким, не устойчив к износу и подвержен старению. Пластик PE отличается хорошей растяжимостью, стойкостью к разрывам и ударам, высокой прозрачностью, возможностью термосварки и хорошими технологическими характеристиками.

Какова функция горизонтальной машины для осушения?

Потому что если вода остается на поверхности пластиковых деталей, она будет испаряться в пузырьки под воздействием тепла, что приведет к образованию гранул с пузырьками, пустотами и другими дефектами, что серьезно повлияет на качество гранул.

Может ли линия гранулирования переработки пластика производить гранулы разных размеров?

Мы можем предоставить вам различные модели машин в соответствии с вашими фактическими производственными потребностями, чтобы вы могли производить пластиковые гранулы нужного вам размера.

Запрос о линии гранулирования пластика

У нас есть специализированное оборудование для переработки пластика по оптовым ценам. Если вы хотите организовать завод по переработке пластиковых отходов, оставьте сообщение на веб-сайте. Мы можем вам помочь.

Выставка завода по переработке чешуек PP PE Shuliy

Случаи экспорта линии гранулирования пластиковых хлопьев PE

Линия по гранулированию пластика мощностью 1 тонна в час от группы Shuliy была успешно установлена в Саудовской Аравии.

Линия гранулирования для переработки пластика может обрабатывать сырьевые материалы, такие как пластиковая пленка, для производства переработанных пластиковых гранул. Основное оборудование включает в себя дробилку, гранулятор и т.д., которые были установлены инженерами Шулиха на месте.

Shuliy предоставила индивидуальную мощность, цвет машины и годовую гарантию, а также поддержала проект защитой при транспортировке и техническим руководством на месте, чтобы удовлетворить высокие требования клиента к производительности с линией гранулирования переработки пластика.