塑料薄膜造粒机是一种塑料回收设备,通过加热、压缩和挤出将塑料转化为颗粒状材料。

塑料制粒机适用于各种塑料原料,包括PP、PE、HDPE、LDPE、PVC、PS等。最终产品是回收利用的塑料颗粒。

Shuliy塑料薄膜回收机的产量范围广,从小型150 kg/h到大型1000 kg/h。

塑料薄膜回收机介绍

Shuliy的塑料薄膜造粒机具有特殊的双螺杆设计,适用于通过回收生产PP、PE、ABS、PVC、PC、PET等塑料颗粒。

螺杆和筒体经过特殊硬化处理,具有耐磨性好、混合性能好和产量高的特点。

PE PP塑料薄膜回收线工作视频

塑料如何通过编织袋回收机变成塑料颗粒?

塑料薄膜造粒机是用于将塑料废料或原材料加工成颗粒的设备。以下是塑料薄膜造粒机将塑料加工成塑料颗粒的基本过程。

- 给料:首先,将塑料废料或原料进给到塑料薄膜造粒机的进料口。薄膜状软塑料需要借助 自动给料机.

- 熔化和塑化:通过电加热器或其他加热方法,将筒体内的塑料材料加热到高温,逐渐软化和熔化。

- 挤出:一旦塑料达到足够的塑化程度,就被推入筒体内的挤出螺杆。

- 冷却和固化:新形成的塑料颗粒通过冷却系统(通常是水)快速冷却和固化。

- 切割:颗粒形成和固化后,通过 塑料颗粒切割机.

塑料薄膜造粒机参数

| YSJ-400 | 150 | 180 | 200 | 220 |

| 螺杆直径 | 150毫米 | 180mm | 200毫米 | 220毫米 |

| 主轴转速 | 40-50/分钟 | 40-50/分钟 | 40-50/分钟 | 40-50/分钟 |

| 主电机功率 | 37千瓦 | 55千瓦 | 75千瓦 | 90kw |

| 减速机 | 250 | 280 | 315 | 330 |

| 输出 | 300kg/h | 350kg/h | 380kg/h | 420kg/h |

这些输出类型可以满足大多数人的生产需求。当然,我们也可以提供具有更大或更小输出的塑料薄膜造粒机。

如果您需要其他容量的塑料薄膜回收机,请随时在我们的网站上留下您的联系信息。我们将立即与您联系,为您定制塑料解决方案。

塑料薄膜回收机生产线解决方案

塑料薄膜回收机通常与废塑料破碎机、塑料清洗机、冷却水箱和造粒机组合成一条生产线,用于加工废旧薄膜材料。

拉伸膜回收线结合了回收机器、破碎机、洗涤机、冷却槽和切割机,其处理效率比单独设备高出300%。例如,自动切割将人工预处理时间减少了70%,而连续洗涤-挤出-造粒循环消除了材料的停机时间。这种精简的工作流程使工业生产线能够在4小时内将1吨废膜转化为可销售的颗粒,这对于满足电子商务和农业领域的高容量回收需求至关重要。

如果您感兴趣,请随时与我们联系。我们将为您推荐最合适的塑料造粒解决方案!请随时与我们联系!

塑料颗粒机的三种模头

塑料造粒机模头通常有三种常见类型:电动齿轮模头、液压模头和自动渣滓过滤模头。

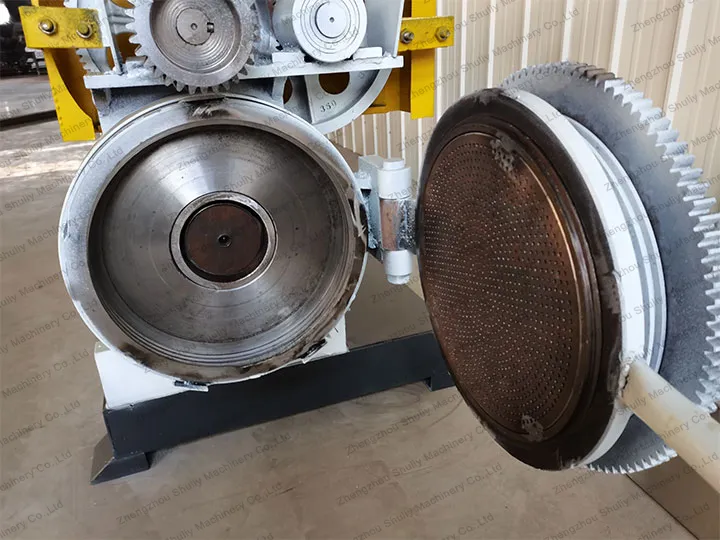

电动齿轮模头

电动齿轮模头是一种常用于塑料造粒机的模头。它通过电动马达驱动的齿轮传动系统将旋转动力传递给螺杆,推动塑料材料进入挤出螺杆,以进行塑化和挤出过程。

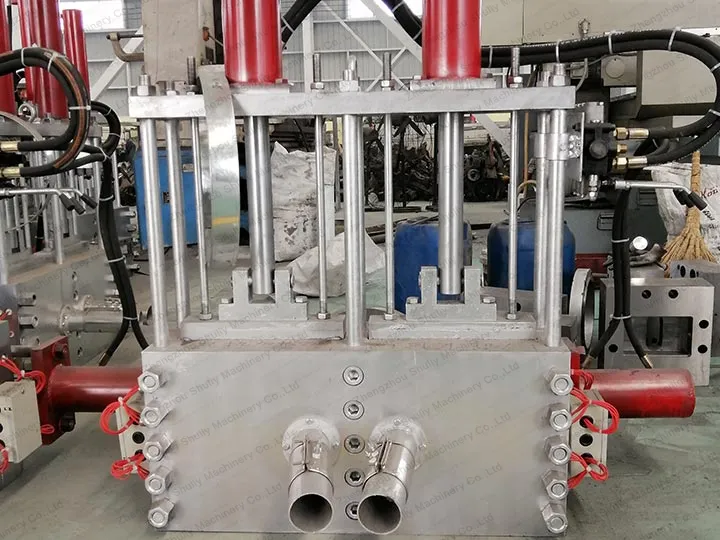

液压模头

塑料造粒线中的液压模头通过液压系统提供的力量将塑料原料推入挤出机的螺杆,从而实现塑料的塑化和挤出过程。

这种模头适用于处理高粘度和高硬度的塑料材料,具有较强的适应性和稳定性。

自动渣滓过滤模头

自动渣滓过滤模头是专为塑料薄膜造粒机设计的一种特殊模头。通过螺杆和渣滓排放口的特殊结构,将塑化的塑料材料从模头排出,无需额外的筛网。

自动渣滤头有效避免了网孔的堵塞,这可能会影响生产效率,并简化了清洁和维护过程。

塑料薄膜造粒机的原材料

Shuliy 塑料薄膜造粒机可加工各种塑料,如塑料薄膜、农用薄膜、编织袋、HDPE瓶、拉菲草袋等。

这里只列举了部分原料。如果您不确定哪种塑料制粒机适合您的原料,请随时与我们联系咨询。

塑料造粒机价格

Shuliy塑料薄膜造粒机的价格从几千美元到几万美元不等。不同型号和产量的造粒机价格各不相同。请通过WhatsApp与我们联系或直接在网站上向我们留言以获取具体报价。

我们塑料颗粒机的特点

- 定制:该机器提供多种型号和规格,输出能力范围为300-420千克/小时,可以根据用户的要求进行定制。

- 增强耐磨部件:螺丝和料筒经过特殊硬化处理,以抵抗磨损并保证长期高负荷生产。

- 安全电力分配设计:分体式自动电力分配系统确保电机安全运行,降低故障风险。

塑料薄膜造粒机的注意事项

- 塑料薄膜造粒机的新机器的齿轮油应至少每六个月更换一次,活动部件应至少每周润滑一次。

- 塑料造粒机的温度必须达到设定温度后,才能倒入清洁材料或原料,清洁螺杆中的残留物,直到新材料挤出,然后暂停挤出,快速安装过滤板和模头。

- 关闭模头后,打开塑料造粒机的主螺杆电机,此时操作员离开模头,以防止模头被硬物堵塞而破裂和伤人。

农业薄膜回收机的成功案例

我们很自豪地宣布,我们的塑料薄膜回收机已成功出口到莫桑比克、沙特阿拉伯、科特迪瓦等许多国家。我们在之前的案例中介绍了这些客户的造粒业务。这些客户通过使用我们的塑料薄膜造粒机获得了可观的利润。

塑料颗粒制造机准备发货

塑料薄膜造粒机的常见问题

冷却后颗粒粘附的原因是什么?

原因:冷却不足或造粒速度不匹配。

解决方案:增加冷却空气/水流量,添加防粘剂(例如滑石粉),并协调造粒和挤出速度以防止熔体积聚。

如何排除设备运行过程中出现的异常噪音?

如果螺杆或齿轮箱出现异常噪音,请检查螺杆与料筒之间的间隙是否有金属异物,更换齿轮箱润滑油,检查轴承磨损情况,并调整传动系统的同心度以减少振动。