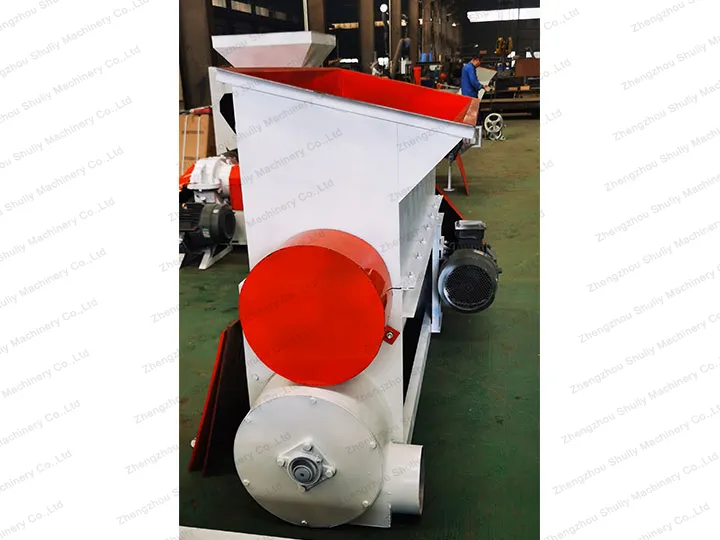

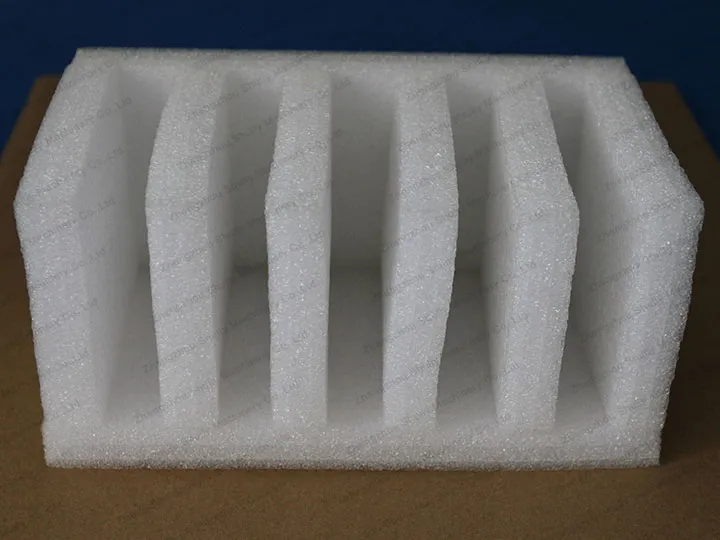

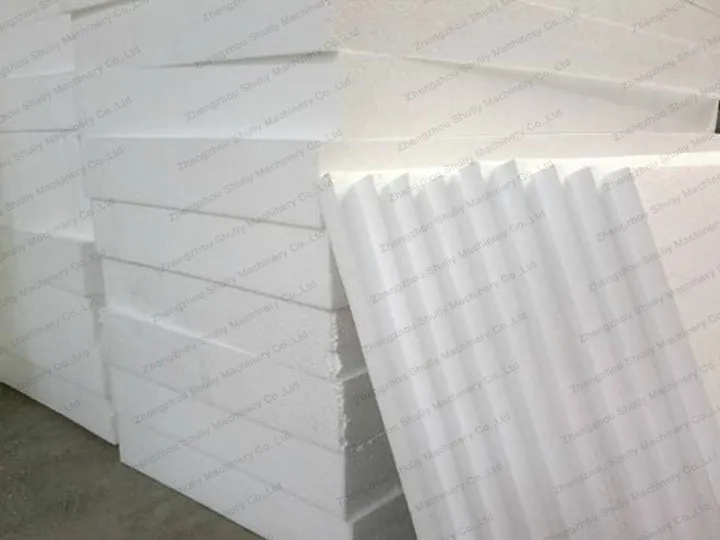

Plastic foam crushers offer the potential to produce a variety of products from recycled foam. The flexibility of this shredder allows for the development of new reuse methods. The Shuliy EPS foam crushing machine tears bulk-expanded polystyrene and many other foams into smaller pieces. These foams come out through a screen before being collected. We offer different screen components. The screen inserts you choose determine the size of foam that can leave the foam shredder machine and continue to be collected.

Introduction of Plastic Foam Crusher

Una trituradora de espuma plástica o una máquina trituradora de espuma EPS es una máquina de reciclaje que convierte bloques de espuma EPS EPE en pedazos triturados para su posterior reciclaje, como la peletización por extrusión. La máquina también reduce el volumen de la espuma para facilitar su transporte.

Shuliy también ofrece una gama de Máquinas trituradoras de espuma EPS para el reciclaje de diversos materiales de desecho. Nuestros productos incluyen trituradoras de un solo eje, trituradoras de dos ejes y trituradoras de cuatro ejes. Son máquinas ideales para triturar botellas de plástico, cintas de plástico, bidones de plástico y diversos productos de plástico. Podemos personalizar la máquina trituradora de espuma según los requisitos del cliente.

Working Principle of Plastic Foam Crusher

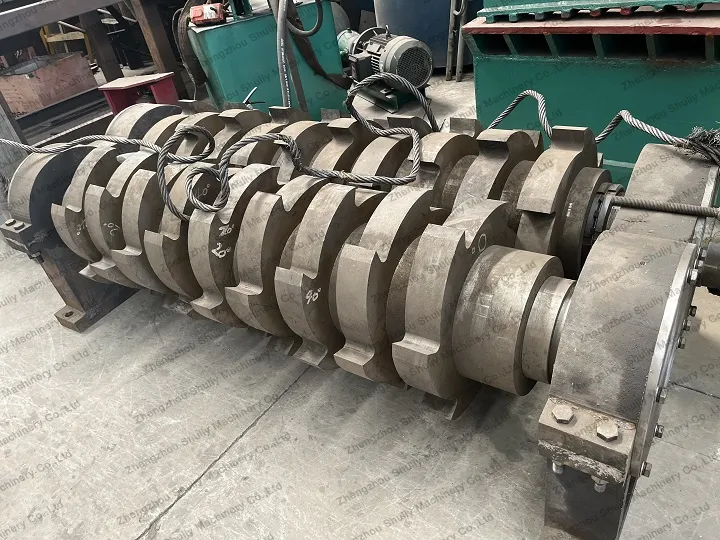

The working principle of the plastic foam crusher is to shear, tear, and extrude the foam material through the high-speed rotating blade or roller to crush the large pieces of EPS, EPE, EPP, and other foams into small particles or fragments, to facilitate the subsequent compression, granulation, or recycling process.

- Feeding: The operator puts large pieces of foam into the machine through the inlet.

- Pre-compression: Foam is fed into the crushing chamber by gravity or screw propeller.

- Crushing: Multiple sets of blades mounted on the spindle rotate at high speeds to quickly cut and tear the foam.

- Screen to control the discharge size: The crushed foam particles are discharged through a screen with an adjustable aperture to control the final discharge size.

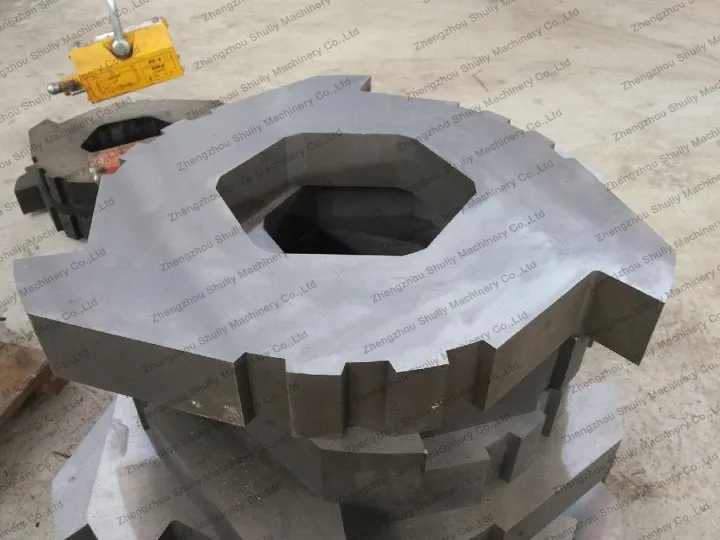

Core Structure and Detailed Design of Styrofoam Shredder

The core structure of the plastic foam crusher includes a reinforced steel frame, a high-torque motor, a rotor system that drives the knife and stator knife, and a replaceable screen unit. These components work together to efficiently crush bulky foam into uniform particles.

High-speed rotary blades

- The tool material is spring steel, high hardness, good wear resistance, and long life.

- The tool supports disassembly and multiple grinding, easy maintenance, and low cost.

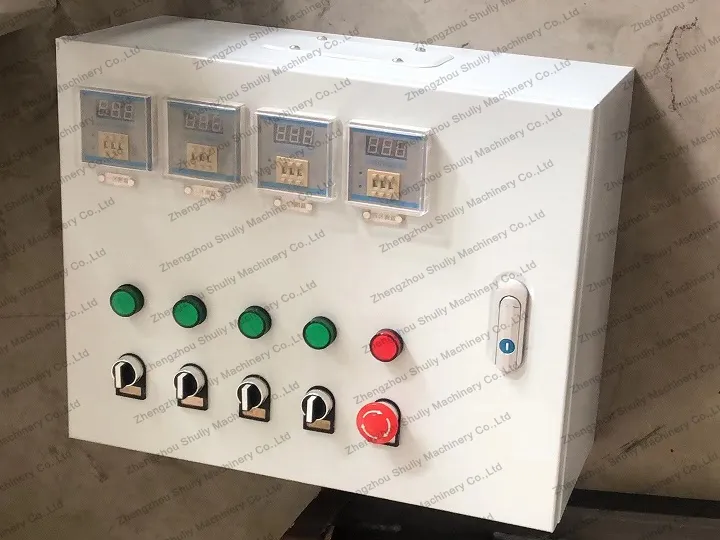

Industrial Control Panels

- The equipment is equipped with a special control box containing digital display instruments, independent control buttons, and an emergency stop system.

- Real-time monitoring of motor status, current and voltage, and running load.

Adjustable screen device

- Use: Control the particle size of foam discharge

- Common aperture: 10 mm- 50 mm (can be customized)

- Material: stainless steel or wear-resistant steel

These parts are the core components of the plastic foam crusher. If you want to know more about the information, please feel free to contact us.

Parameters of EPS Foam Crusher

| Modelo | Fuerza | Capacidad |

| SL-800 | 5,5 kw | 150-250kg/hora |

| SL-1000 | 5,5 kw | 280-350kg/hora |

| SL-1500 | 7,5 kw | 450-500kg/hora |

Optional Configuration of Styrofoam Crusher

| Mahcines | Functions |

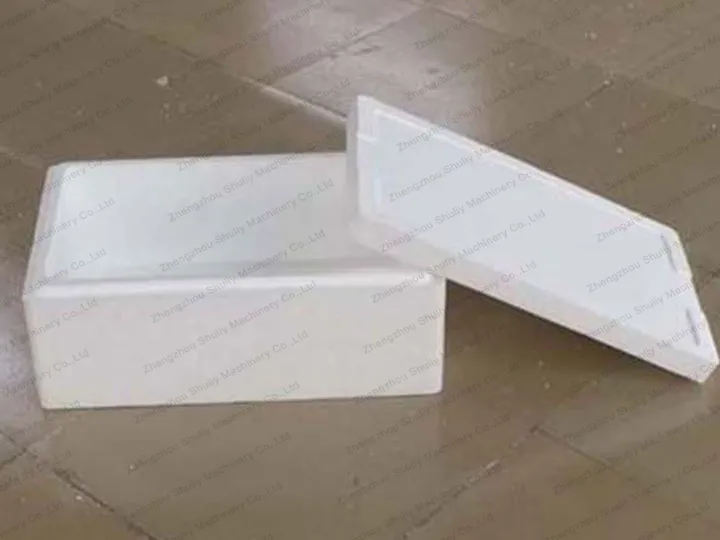

| Máquina compactadora de espuma | Styrofoam compactors compress bulky foam waste (e.g., EPS, EPE) into high-density blocks to reduce volume for storage, transportation, or subsequent recycling. |

| Extrusora de espuma plástica | Plastic granulator is used to process waste plastics into reusable plastic pellets for re-production through melting, filtering, drawing, and other processes. |

| Tanque de enfriamiento | Cooling tanks are used to rapidly cool the extruded plastic strips during the plastic pelletizing process to ensure that they are hardened and molded for easy pelletizing. |

| Cortador de gránulos de plástico | A plastic pellet cutter is used to cut cooled plastic strips into uniform granules for subsequent storage, transportation, and reprocessing. |

Raw material of EPS Foam Crushing Machine

La máquina trituradora de espuma Shuliy EPS puede triturar EPS, EPE, espuma de polietileno, espuma de poliuretano, espuma viscoelástica y la mayoría de los tipos de espuma en trozos más pequeños. Y no es necesario compactar la espuma como otras trituradoras. La trituradora está diseñada para espuma, por lo que puede funcionar de forma continua sin los problemas que surgen con otros métodos.

Features of polystyrene shredding machines

| Features of EPS foam shredder | Details of styrofoam crusher |

| Robust tool construction | 1. Equipped with 4 fixed knives and 6 movable knives, it has strong cutting ability for dense or elastic foam materials. 2. The blade material is made of 60Si2Mn high-quality spring steel with excellent wear resistance and toughness. |

| Thickened carbon steel structure body | 1. The fuselage is welded by a 20 mm-thick A3 carbon steel plate, which is durable and not easy to be deformed. 2. Suitable for high-intensity continuous operation to meet the needs of harsh working conditions. |

| Optimized feeding and discharging control | 1. Large size feeding opening (600×500mm), suitable for large foam feeding. 2. Equipped with a 24mm screen (customizable) to control the size of crushed particles. 110mm spindle diameter ensures stable torque and smooth operation. |

| Industrial Grade Performance | 1. 22 kW motor provides continuous power for high-load lines. 2. Capacity up to 800 kg/h for foam granulation or compression lines. |

Styrofoam Shredder Fan

La máquina trituradora de espuma Shuliy EPS está equipada con un ventilador de escape que transporta el material a través de la trituradora hasta una bolsa recolectora. Este método funciona limpiamente y empaqueta la espuma triturada en un solo paso.

FAQs of Plastic Foam crusher for sale

What is the typical size of crushed foam particles?

The general particle size of the discharged material is 10-50 mm, which can be adjusted by replacing the screen mesh.

Are the blades of the EPS foam shredder easy to replace or sharpen?

Yes, the blades in the styrofoam shredder are removable and support multiple sharpenings and reuse.

Can a styrofoam shredder be connected to a pelletizing line or compression plant?

Yes, the equipment supports linkage with back-end pelletizing lines or compression systems for automated recycling.