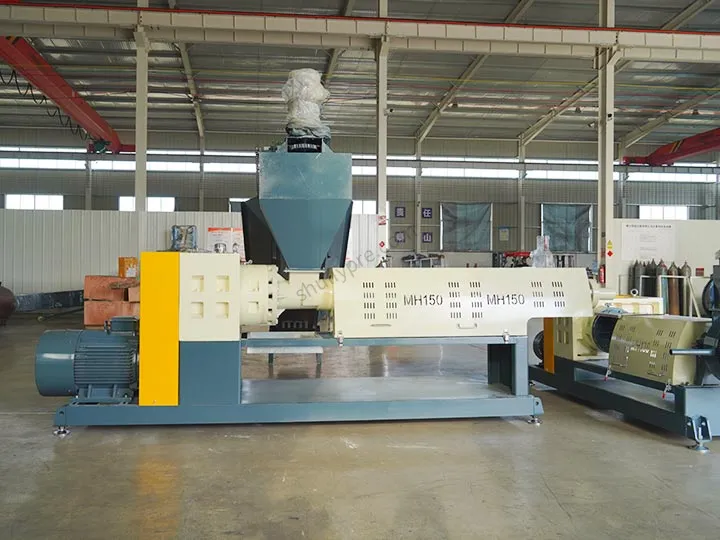

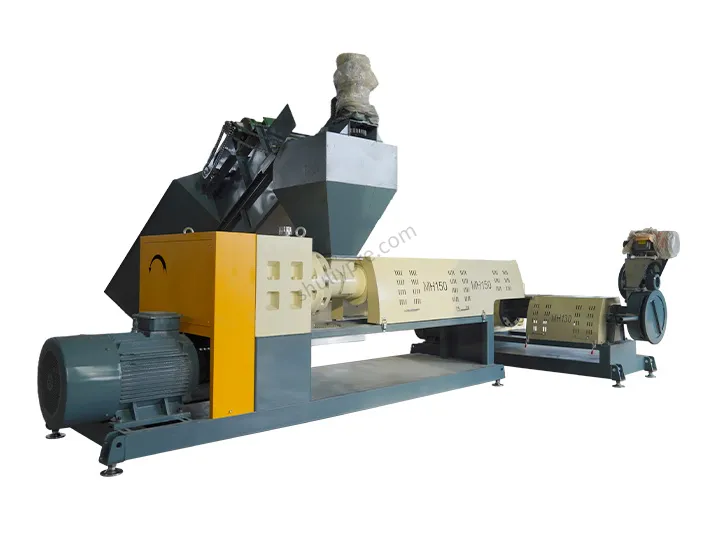

La machine granulateur de sac tissé Shuliy, également connue sous le nom de machine de granulation PP, est un équipement spécialisé dans la conversion des sacs tissés usagés en granulés de plastique. Les granulateurs de sacs tissés peuvent être utilisés pour recycler les sacs en plastique jetés tels que les sacs en peau de serpent, les sacs en tonnage, les sacs en raphia PP, les sacs en ciment, etc.

Introduction de la machine à granulés en plastique

La machine granuleuse pour sacs tissés est un équipement spécialisé pour la granulation de sacs tissés, de sacs en raffia et de sacs de ciment.

Après que les morceaux ont été broyés, la machine chauffe et plastifie ces matériaux de sacs en plastique, puis les extrude et les coupe en granulés uniformes à travers le moule.

Ces granulés peuvent être utilisés dans des industries telles que l'emballage, l'artisanat et les matériaux biodégradables. Ils aident à convertir les déchets plastiques en ressources précieuses, favorisant l'utilisation durable des matériaux naturels.

Vidéo de la machine à granuler le recyclage

Cette vidéo montre une machine à granulés en plastique en action, montrant comment un sac tissé est transformé en granulés de plastique.

Principe de fonctionnement de la machine à granuler les sacs tissés

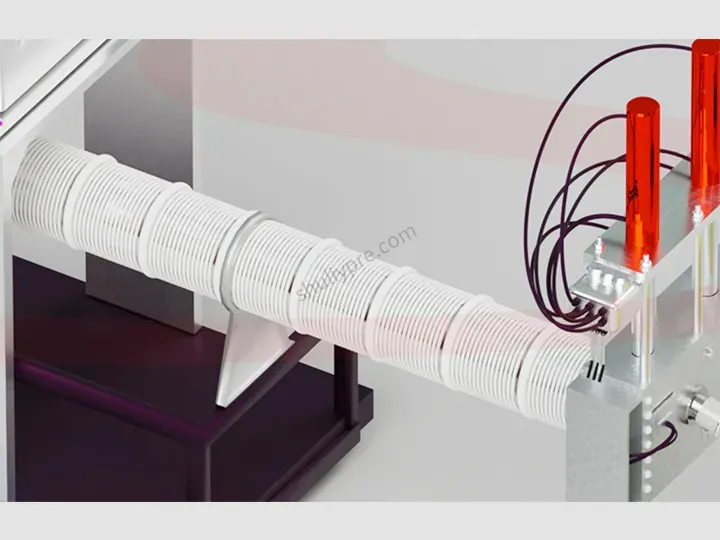

Le principe de fonctionnement de la machine granulateur de sac tissé comprend principalement les étapes de broyage, fusion, extrusion et granulation du sac tissé.

Tout d'abord, les sacs tissés usagés sont introduits dans le broyeur, qui les réduit en petits morceaux.

Ensuite, ces fragments sont introduits dans la machine de granulation des sacs tissés, qui convertit les sacs tissés usagés en un état fondu grâce au processus de chauffage et de fusion.

Enfin, le plastique fondu est extrudé à travers la forme de la filière ou la sortie de l'extrudeuse de la machine de recyclage de sacs tissés et est transformé en un matériau granulaire après refroidissement.

Présentation des matières premières pour le recyclage des sacs tissés

La machine granuleuse pour sacs tissés est utilisée pour les sacs tissés en PP, PE, sacs en raffia, sacs jumbo, sacs en plastique, sacs de ciment, sacs à serpents, etc.

Processus de travail de la machine à granulés en PP

Alimentation : la vis dans le convoyeur d'alimentation envoie des morceaux de plastique à granuler de manière continue et uniforme, ce qui garantit la stabilité du déchargement. De plus, la machine remplace le fonctionnement manuel et améliore la production.

Chauffage : Le chauffage électromagnétique de cette machine à granuler de recyclage fait fondre les morceaux de déchets en une pâte.

Extrusion : Ce moule hydraulique automatique extrude la pâte en bandes pour une coupe ultérieure.

Recommandations de configuration pour la machine granulateur de sac tissé

Le choix de la machine granulateur de sac tissé appropriée nécessite de prendre en compte le degré de propreté du sac tissé et l'effet de granulation souhaité. La propreté de la matière première peut influencer le choix du type et de la configuration de la machine granulateur de sac tissé. Voici quelques suggestions pour choisir la bonne machine granulateur de sac tissé.

Broyage

Si le sac tissé contient plus d'impuretés ou de polluants, il est recommandé de choisir une machine à granuler pour sacs tissés avec un puissant système de broyage. Un broyeur en plastique à double arbre est recommandé afin que les sacs tissés ne s'emmêlent pas dans l'machine de broyage en plastique. De plus, les plastiques souples tels que les sacs tissés sont généralement choisis avec un alimentateur automatique, une machine à granuler pour sacs tissés.

Lavage

La propreté des sacs tissés peut être classée en deux situations : sacs tissés propres et sacs tissés avec contaminants. Les sacs tissés propres sont généralement exempts de contaminants évidents et d'objets étrangers, tandis que les sacs tissés avec contaminants peuvent contenir des impuretés, de l'huile, etc. Il est recommandé aux fabricants ayant des exigences de qualité élevées pour les produits finis de configurer une machine de lavage en plastique. La propreté de la matière première a un impact plus important sur les granulés plastiques.

De plus, Shuliy peut personnaliser différentes solutions de recyclage en fonction des diverses exigences et répondre aux besoins personnalisés.

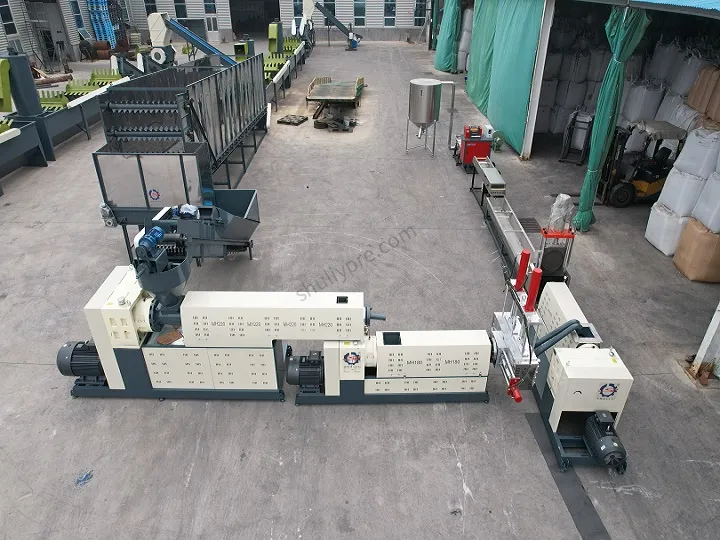

La machine à granuler pour sacs tissés est la principale partie de la ligne de production de recyclage plastique. Si elle est utilisée en conjonction avec d'autres machines pour former une ligne de granulation de recyclage plastique complète, le taux d'utilisation de l'équipement peut être maximisé.

Si vous avez des besoins à cet égard, n'hésitez pas à nous contacter.

Avantages de la machine de granulation de recyclage en PP

Efficace et gain de temps : La tête de moule hydraulique de cette machine n'a pas besoin d'être arrêtée pour changer, ce qui permet d'économiser plus de temps par rapport à la tête magique à pignons traditionnelle.

Économie d'énergie et durable : Le dispositif de chauffage adopte le chauffage électromagnétique au lieu de la méthode traditionnelle de chauffage par plaque en céramique, ce qui est non seulement économe en énergie mais aussi a une durée de vie plus longue.

Cas mondiaux de machines à granuler pour le recyclage

Machine à granuler pour sacs tissés Shuliy à vendre en Arabie Saoudite, et nos ingénieurs se rendront sur place pour aider les clients à installer.

FAQ sur la machine à granuler pour sacs tissés

Quel est le produit final de cette ligne, et dans quels domaines ce produit peut-il être utilisé ?

Le produit final est des granulés plastiques. Ces granulés trouvent de nombreuses applications dans plusieurs domaines. Par exemple, dans l'industrie de l'emballage, les granulés sont utilisés pour produire des films plastiques et des sacs en raffia ; en agriculture, pour fabriquer des films agricoles et des tuyaux ; dans les articles de tous les jours pour le traitement des jouets et des meubles.

Quelles sont les méthodes pour recycler les sacs tissés usagés ?

Si vous souhaitez démarrer une entreprise de granulation à partir de sacs tissés usagés, vous pouvez envisager les moyens suivants pour trouver des sacs tissés usagés :

Stations de recyclage des déchets et points de collecte des ordures : Travaillez avec vos stations de recyclage des déchets locales, points de collecte des ordures ou centres d'élimination des déchets pour obtenir des sacs tissés usagés.

Supermarchés et détaillants : Travaillez avec des supermarchés, centres commerciaux ou détaillants qui ont généralement de grandes quantités de sacs tissés usagés.

Chantiers de construction et zones industrielles : Les chantiers de construction et les zones industrielles utilisent souvent des sacs tissés pour transporter des matériaux de construction ou des objets.

Les pièces de cette machine peuvent-elles être personnalisées ?

Les parties de la machine granulateur de sacs tissés peuvent être adaptées, telles que la taille du pelletiseur, les granulés, les bandes, et le moule hydraulique automatique ainsi que la longueur de la vis dans le convoyeur d'alimentation.

Si vous souhaitez connaître des informations plus détaillées ou d'autres informations, n'hésitez pas à nous contacter afin que vous puissiez obtenir vos solutions personnalisées.