Le réservoir de refroidissement est utilisé pour refroidir les longues bandes de plastique souple extrudées par la machine auxiliaire de granulation pour une coupe facile par la machine de découpe de granulés de plastique.

Un équipement de refroidissement en plastique est un élément essentiel largement utilisé dans le recyclage du plastique, la granulation et la production par extrusion. Son principal objectif est de refroidir rapidement les brins ou granulés de plastique chauds après l'extrusion ou la coupe. L'utilisation d'un réservoir de refroidissement garantit que le produit se solidifie uniformément, conserve sa forme et est prêt pour un traitement ultérieur tel que le séchage, le transport ou l'emballage.

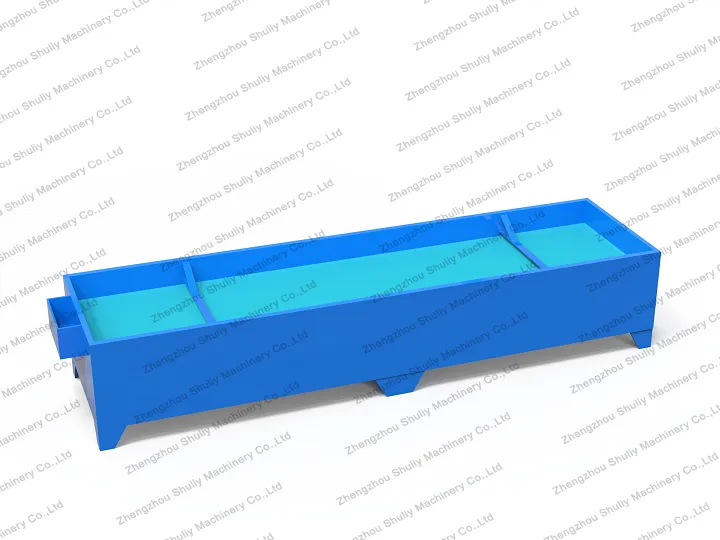

Introduction au réservoir de refroidissement

Une machine de refroidissement est une machine importante dans une ligne de recyclage de film plastique, qui peut refroidir et façonner les longues bandes de plastique à haute température.

Shuliy Machinery a de nombreuses années d'expérience dans la fabrication de réservoirs d'eau de refroidissement. Si vous êtes engagé dans le secteur du recyclage des plastiques et avez besoin d'utiliser une machine de refroidissement, veuillez nous contacter.

Paramètres du réservoir d'eau de refroidissement

En général, la machine de refroidissement en plastique de Shuliy Machinery mesure 2,5 m de long et 0,4 m de large, fabriquée en acier inoxydable.

- acier inoxydable

- longueur de 2,5 m

- largeur de 0,4 m

Bien sûr, si vous avez des exigences spéciales, nous pouvons la fabriquer selon vos besoins.

Principe de fonctionnement du Cooltank de granulation plastique

Dans un bain de refroidissement de granules plastiques, des granules ou des brins de plastique chauds sont immergés dans de l'eau de refroidissement circulante.

Flux de processus de la machine de refroidissement en plastique :

Étape 1 :

- Les granulés de plastique chaud entrent dans le réservoir et sont immédiatement immergés pour éliminer la chaleur.

Étape 2 :

- L'eau circulante absorbe la chaleur et maintient les granulés à des températures uniformes et sûres.

Étape 3 :

- Les granulés solidifiés sortent du réservoir de refroidissement prêts pour le séchage, la découpe ou l'emballage.

Le système de refroidissement de la ligne de granulation empêche l'agglomération des granulés et garantit la cohérence de leur forme pour des produits finis de haute qualité.

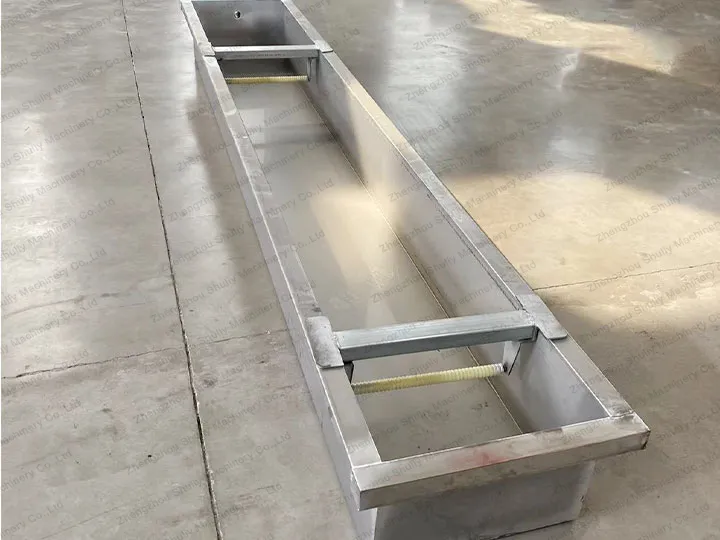

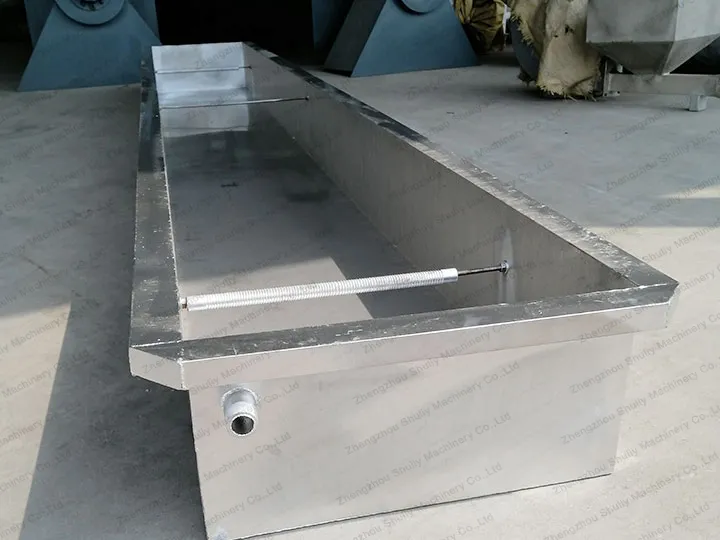

Structure et caractéristiques du réservoir de refroidissement en acier inoxydable

La machine de refroidissement en plastique fabriquée par Shuliy Machinery est en acier inoxydable. D'une part, le matériau en acier inoxydable peut résister à la chaleur élevée du plastique pendant longtemps, ce qui la rend moins sujette à la déformation. D'autre part, la surface en acier inoxydable est lisse, n'adhère pas facilement à la saleté et est facile à nettoyer.

- Corps de réservoir en acier inoxydable de haute qualité : Assure la résistance à la corrosion et l'hygiène, est facile à nettoyer et à entretenir.

- Cadre renforcé et pieds réglables : Offre une stabilité sur divers sols d'usine.

- Dimensions personnalisables : La longueur, la largeur et la profondeur peuvent être adaptées à votre ligne de production.

Importance et applications du réservoir d'eau de refroidissement industriel

La bande plastique fondue est très chaude et se déforme facilement, donc la machine de coupe de granulés plastiques ne peut pas couper la bande en petits particules ; elle doit être refroidie au préalable.

Le système de refroidissement industriel est adapté pour :

- Systèmes de refroidissement pour la granulation de plastique : Pour PP, PE, PET, PVC, ABS et autres plastiques.

- Systèmes de refroidissement pour l'extrusion de plastique : Pour tuyaux, profils, feuilles et filaments.

- Lignes de refroidissement pour l'extrusion de câbles et de caoutchouc : Assure la forme et la résistance avant l'enroulement ou la coupe.

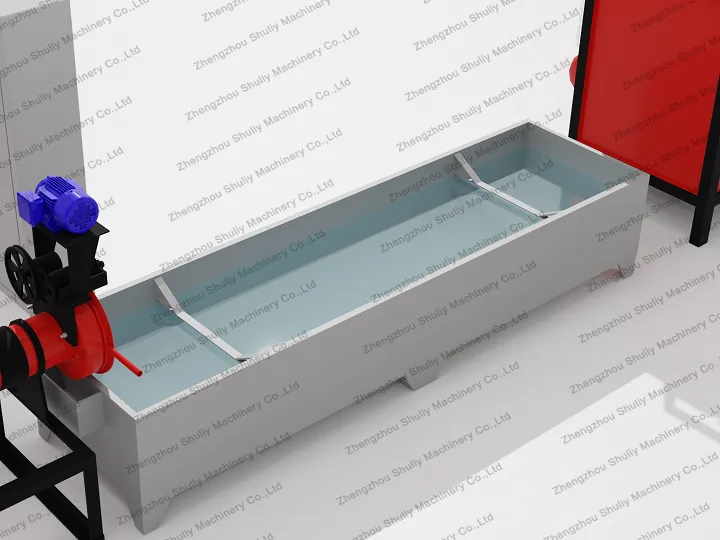

Emplacement de la machine de refroidissement en plastique dans la ligne de granulation plastique

Le réservoir d'eau de refroidissement est placé après la machine de granulation plastique et avant la machine de coupe de granulés plastiques. Les bandes plastiques à haute température extrudées par la machine auxiliaire de pelletisation entrent directement dans le réservoir d'eau de refroidissement, et les bandes plastiques refroidies sont transportées à travers la machine jusqu’au pelletiseur.

Comment choisir le bon bain de refroidissement pour les brins

Choisir le bain de refroidissement approprié pour l'extrusion de plastique pour votre ligne de production implique :

- Type de matériau et besoins en refroidissement (par exemple, le PP et le PET nécessitent des longueurs de refroidissement différentes).

- La capacité de production et la vitesse de la ligne sont utilisées pour déterminer la taille du réservoir.

- Espace disponible dans votre installation et considérations de mise en page.

Réservoir d'eau de refroidissement fabriqué par Shuliy Machinery

Ce sont des systèmes de refroidissement de ligne de granulation fabriqués par Shuliy Machinery, et l'image montre les détails du système de refroidissement par extrusion.

Questions fréquentes sur les réservoirs de refroidissement

Quel type d'eau est recommandé pour une utilisation dans les réservoirs de tours de refroidissement ?

De l'eau propre et filtrée ou de l'eau adoucie est recommandée pour réduire l'entartrage et prolonger la durée de vie de l'équipement.

Que doit-on vérifier avant de démarrer le refroidissement du réservoir d'eau ?

Vérifiez le niveau d'eau, le fonctionnement de la pompe à eau et la propreté du réservoir pour garantir un fonctionnement fluide.