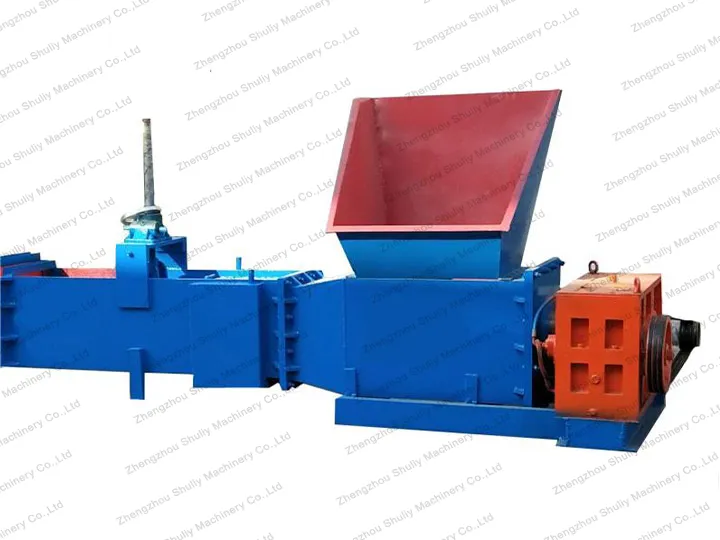

A foam compactor machine is a compression machine for foam that combines a shredder and a compressor into one. The foam packaging machine can reduce the volume of foam exponentially, increase the density, and facilitate the recycling of foam.

Introduction of the Foam Compactor Machine

Пенопласт EPS EPE сжимается с помощью компактора для переработки пенопласта EPS, его плотность увеличивается и становится квадратными блоками. Значительно сокращается площадь, что позволяет снизить транспортные и хранительские расходы.

EPS styrofoam recycling compactor is the necessary equipment for the линии пластикового гранулирования пены.

The cold briquette press machine is an environmental protection equipment that generates pressure according to the spiral rotation, squeezes the foam, and cold presses it for compression processing.

The styrofoam compactor can effectively solve the problem of EPS and EPE foam, which is difficult to recycle and inconvenient to transport. The Shuliy foam packaging machine’s compression ratio is high. The EPS styrofoam recycling compactor is cold pressed, no other chemical products are added, and no odor is produced.

Principle of the Styrofoam Compactor

A styrofoam compactor, also known as a foam densifier or EPS recycling machine, typically operates in two stages. First, loose foam is fed into the hopper and shredded into smaller particles. Then, through either cold or heat-assisted compression, the machine compacts the material into dense bricks or logs.

Cold press hydraulic baler use a screw mechanism to push foam through a compression chamber, while styrofoam densifier use heating elements to melt and extrude EPS into lumps. Both designs are intended to reduce foam waste volume while producing recyclable output for downstream use or resale.

How does a Foam Packing Machine Work?

При использовании оператору достаточно положить пену в загрузочный бункер, через механизм измельчения и дробления разрушить пену в спиральной компрессии. После спирального механизма пена превращается в квадратный сжатый блок пены. Это позволяет значительно уменьшить объем пены, увеличить плотность и облегчить переработку пены.

Feeding:

The process begins with feeding the loose EPS foam into the large hopper. The wide feed opening allows for direct loading of large foam boxes, sheets, or blocks without pre-cutting.

Breaking:

Inside the hopper or feed chamber, rotating blades or screw shafts break the foam into smaller pieces.

Compression:

The broken foam pieces are then pushed into the compression chamber. Using mechanical or hydraulic force, the material is compacted into high-density blocks.

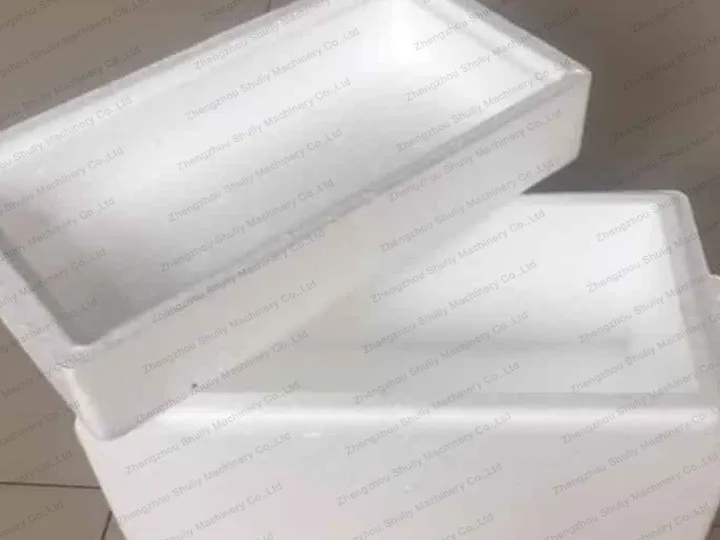

Formating:

Once compressed, the foam is extruded from the output end in the form of rectangular blocks or logs. These blocks are uniform in size, easy to stack, store, or transport.

The compressed foam blocks can be collected manually or via conveyor and stored on pallets. These blocks can later be sold as recycled materials or sent to pelletizing lines for further granulation.

Parameters of Hydraulic Cold Press

| Модель | YSJ-300 | YSJ-350 | YSJ-400 |

| Мощность | 11 кВт | 11 кВт | 15 кВт |

| Коэффициент сжатия | 40:01:00 | 40:01:00 | 40:01:00 |

| Размер входа | 600*800*1400 мм | 800*900*1400 мм | 800*1000*1600 мм |

| Размер выхода | 280*280 мм | 350*350 мм | 400*400 мм |

| Производительность | 400-600 кг/ч | 600-800 кг/ч | 800-1000 кг/ч |

Two types of Cold-press Styrofoam Compactors for Sale

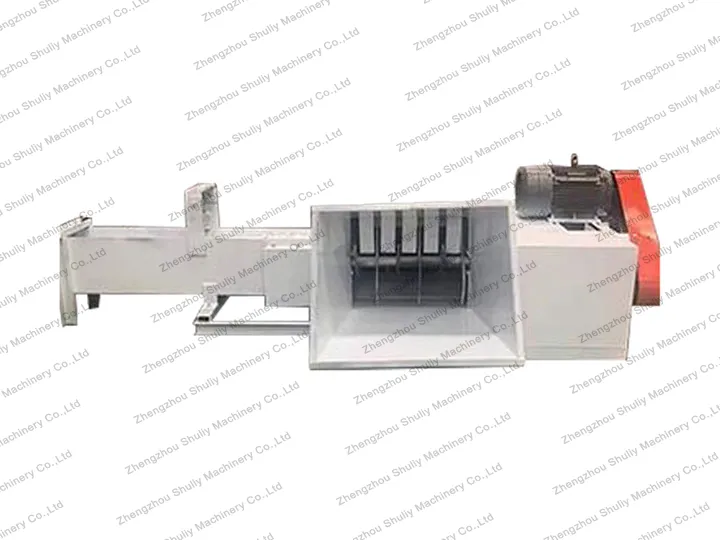

Horizontal Cold Press Machine

The horizontal cold press machine features a side-feeding structure where materials are loaded and compressed along a horizontal axis.

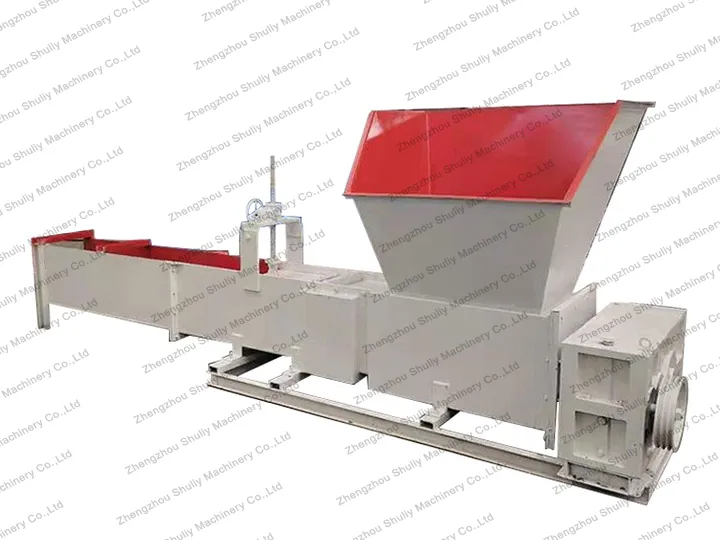

Vertical EPS foam compactors

The vertical styrofoam compactor machine operates on a top-down compression axis. Material is loaded from the top and compressed downward, making it space-saving.

Особенности компактора для переработки пенопласта EPS

- Safety and environmental protection: The styrofoam compactor machine is designed for environmental protection, high quality, and low energy consumption. The briquettes are not heated, non-toxic, and harmless, saving energy.

- Простота применения: Коэффициент сжатия машины для упаковки пены большой и регулируемый. Сжатая пена позволяет экономить место для хранения и снижает транспортные и хранительские расходы.

- Durable: Shuliy’s styrofoam recycling compactor has a long and durable service life.

Materials handled by Foam packing machine

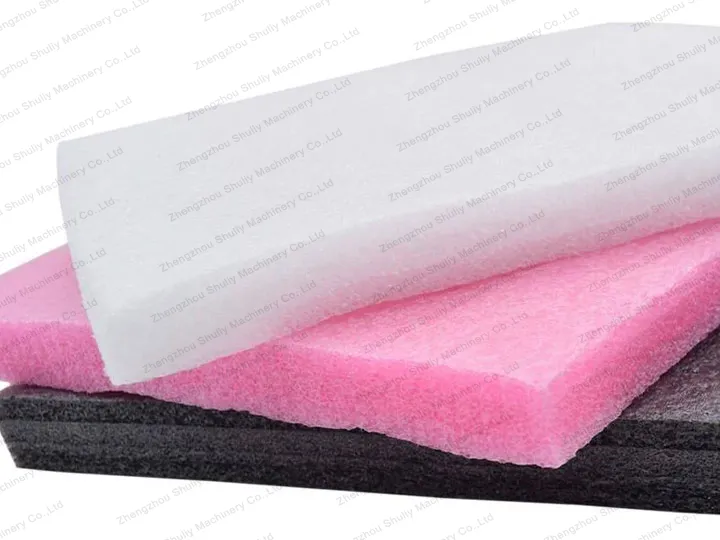

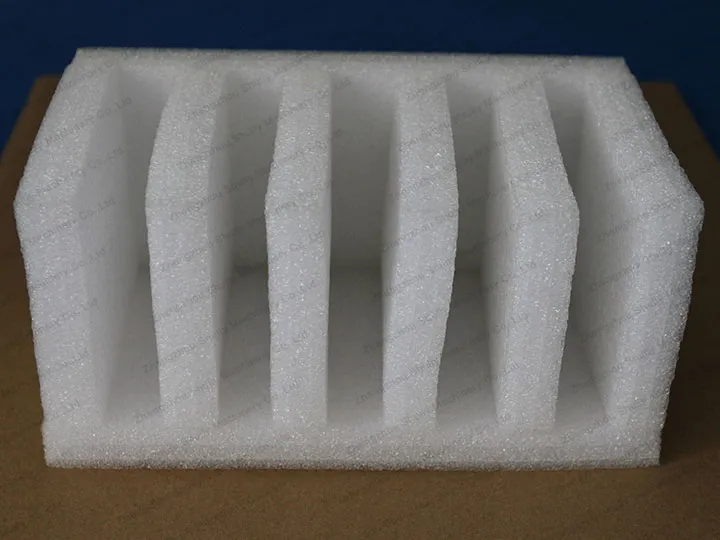

Shuliy foam packaging machines can be used for fast food boxes, foam boxes, foam boards, pearl cotton sticks, and other EPS and EPE foam.

Notes on Styrofoam Compactor

- When using a styrofoam compactor machine, pay attention to the buttons on the machine. Especially the “up”, “down”, and “emergency switch”, which are used in case of emergency.

- Proper operation of the foam press also includes routine maintenance and timely cleaning. It is important to ensure that the upper and lower plates are clean and flat to avoid damage to the product during pressing.

- Каждый раз, когда вы работаете на прессе для компактирования пены, необходимо заранее подготовить все виды вспомогательных материалов, чтобы избежать простоя, вызванного нехваткой материалов при обработке.

Export of Cold Press Foam Compressors to Malaysia

A Malaysian client installed our cold-press foam compactor, who is dealing with EPS foam waste from furniture and electronics packaging. With a wide feed inlet and efficient screw compression, the machine reduced foam volume by around 85%. The compacted blocks are now recycled locally, significantly reducing transport and storage costs.

FAQs of Cold Press Baling Press

What is the difference between a cold press and a hot melt machine?

Cold presses do not heat and maintain the nature of the raw material; hot melt machines plasticize by melting at high temperatures.

Can I adjust the density of the compressed foam blocks?

Yes, by adjusting compression ratio and screw speed.

What kind of power supply does it require?

Most models require 3-phase industrial power (e.g., 415V, 50Hz), depending on the model.