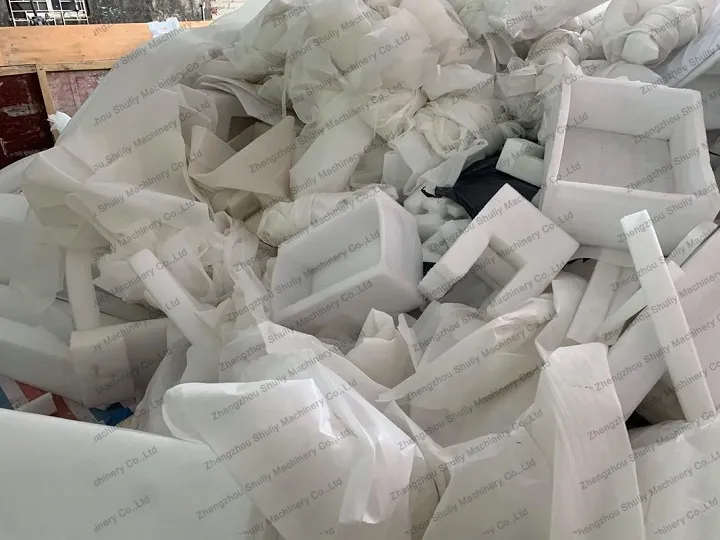

泡沫塑料造粒线是专为泡沫塑料回收造粒而设计的解决方案。近年来,泡沫在包装行业得到广泛应用,但其体积较大,运输困难。这带动了泡沫回收和再利用机械设备的快速发展。随着新技术的不断采用,发泡聚苯乙烯回收机的设备技术和生产效率普遍得到快速提高。

塑料泡沫颗粒化生产线介绍

塑料泡沫造粒线通过压缩、破碎、加热、熔化、挤出和造粒等工艺高效回收废泡沫,具有高产量、低能耗、稳定运行等特点,适用于聚苯乙烯等,将废料转化为可重复使用的颗粒,以提高资源利用率和环境保护。

用于塑料泡沫回收的膨胀聚苯乙烯造粒机是一种集成的工业系统,旨在将废弃塑料泡沫回收成可重复使用的塑料颗粒。该过程将低价值、体积庞大的泡沫废料转化为高质量的新塑料生产原料。该生产线通常结合机械破碎、热熔和造粒技术,以实现高效的材料回收,解决环境污染和资源稀缺的挑战。

EPS泡沫回收和造粒的工作视频

塑料泡沫颗粒化生产线工艺流程

破碎——结块——拉丝——冷却——造粒

塑料泡沫造粒生产线100%可用于回收泡沫。EPS EPE泡沫经过压缩后进行造粒,是最广泛回收的加工方法。泡沫通过专业的泡沫压缩机进行压缩或热熔,形成压缩块。 shredded泡沫压缩块可用于造粒,生产高质量的EPS EPE颗粒。它可以应用于新泡沫产品的生产。如今,随着碳减排的日益普及,回收已成为再生EPS的主要方法。

在EPE EPS泡沫造粒生产线中,EPE和EPS造粒之间存在一些差异。EPE泡沫是柔软的,处理这种泡沫的造粒机通常包含一个自动喂料装置。此外,EPE泡沫不需要预处理的破碎机,因此可以直接放入造粒机中。

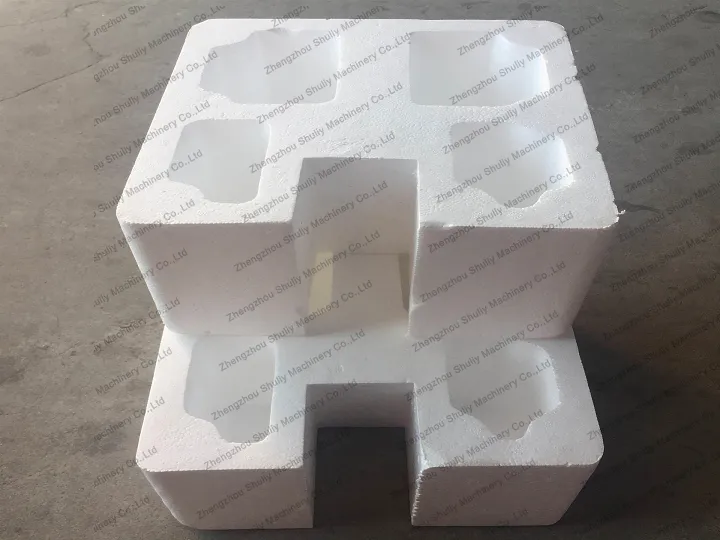

EPS泡沫通常是大尺寸的,这意味着EPS泡沫需要通过破碎机进行粉碎和压缩。因此,这种泡沫可以进入造粒机进行加工。

塑料泡沫造粒生产线的主要设备

塑料泡沫破碎机

塑料泡沫破碎机用于将大块回收泡沫破碎成易于熔化和造粒的小块。

如果您想回收泡沫但不知道选择哪种机器,请在网站上留言给我们。我们将为您设计出完整的解决方案。

由于泡沫的低密度和大体积,粉碎后需要通过泡沫压缩机进行压缩,以提高材料运输效率。

塑料发泡挤出机

塑料泡沫挤出机用于将破碎的小块塑料泡沫熔化并挤出成长条。

Cooling tank

冷却槽用于对高温塑料条进行冷却,使之硬化,便于切割。

塑料颗粒切割机

塑料颗粒切割机用于将冷却硬化的塑料长条切割成尺寸均匀的塑料颗粒。

EPS泡沫颗粒化生产线的具体配置可以根据客户的个性化需求进行调整。欢迎随时与我们联系,我们将为您量身定制完美的回收解决方案。

塑料泡沫造粒线的原材料和成品

泡沫塑料造粒线可以利用回收的废泡沫生产塑料颗粒。

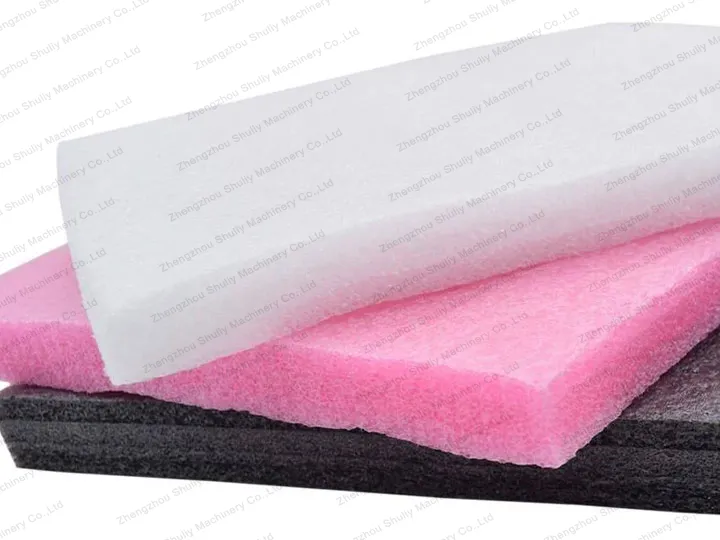

发泡聚乙烯

发泡聚乙烯是一种由聚乙烯聚合物制成的结构泡沫。它是通过加热和压缩聚乙烯聚合物以形成气泡而制成的,使其重量轻、柔韧,并具有隔音和隔热性能。它主要用于包装、建筑和家庭应用。

发泡聚苯乙烯

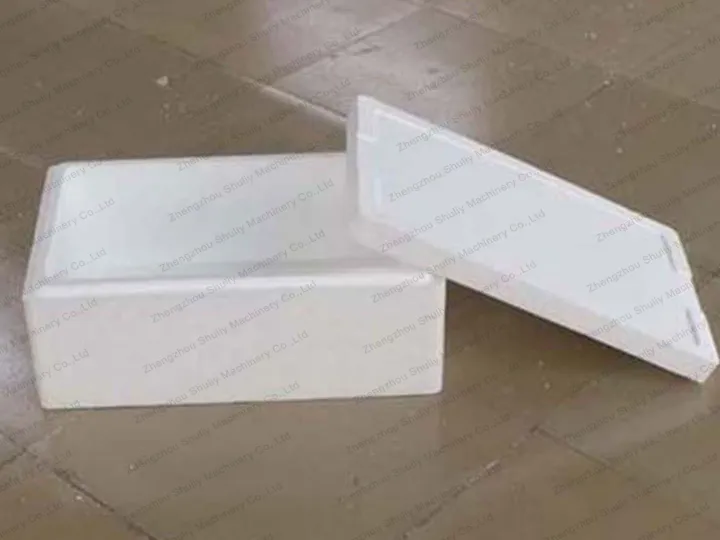

EPS(即发泡聚苯乙烯)是一种轻质、刚性的热电偶材料,由聚苯乙烯小颗粒制成。 EPS 因其成本低、多功能性和良好的绝缘性能而常用于绝缘、包装和保护性缓冲应用。

为了制造 EPS,聚苯乙烯小颗粒与丙烷等充气机混合,然后加热并模制成大块。充气机在颗粒内部形成小气泡,使它们膨胀并形成有机体。根据所需的应用,可以控制膨胀过程以生产具有不同密度和物理特性的 EPS。

如果您不太确定您现有的材料是否可以在EPE EPS泡沫颗粒化生产线上造粒,请随时在我们的网站上留言。我们会及时与您联系。

回收塑料颗粒的应用

EPE EPS材料因其质轻、弹性、防潮、防震、耐腐蚀等特性,被广泛应用于以下领域。

- 包装:它通常用于包装电子产品、食品、化妆品、工业品和其他物品,以保护它们在运输过程中免受损坏。

- 建筑:发泡聚乙烯常用于建筑,如用于墙体隔断、隔音、隔热、防护等。

- 家具:常用于制造沙发、座椅、床垫、枕头等家具,以提供舒适和良好的支撑。

- 运动器材:常用于干法制造运动器材,如跳水板、防护装备等。

- 电子产品:常用于干法制造电子产品,如手机壳、电脑包、摄影设备等。

塑料泡沫颗粒化生产线的特点

扩展聚苯乙烯回收机用于回收和造粒EPE和EPS泡沫。它特别适合材料分类,将废物变为宝藏。

- 高生产能力: 塑料泡沫造粒线,具有250 kg/h的生产能力,确保高效处理大规模泡沫废料。

- 技术设计与美观保护: 塑料泡沫颗粒化生产线采用最新技术,外观配有保护罩,外形大方美观,使用方便。

- 自动化连续生产塑料泡沫造粒机生产线可以实现自动化、连续生产。

EPE EPS泡沫颗粒化生产线出口案例

在2025年,一家前瞻性的墨西哥塑料回收公司选择了Shuliy的SL-180 EPE泡沫颗粒机。面对处理大量EPE薄膜和泡沫包装废料的挑战,客户需要一个高效的解决方案,将这些笨重的材料转化为有价值的颗粒。SL-180系列以其250公斤/小时的产能、坚固的结构和用户友好的设计,证明是理想的选择。

出口的SL-180 EPE造粒线,生产率为250 kg/h,帮助墨西哥客户提高回收效率,减少填埋废物,并通过销售高质量颗粒创造新的收入来源。

塑料回收机常见问题解答

EPE、EPS泡沫造粒生产线的典型生产能力是多少?

塑料泡沫造粒生产线的生产率为200-250公斤/小时,具体取决于您的原材料。

如果您需要更详细的信息,请随时与我们联系。

湿泡沫可以直接在塑料泡沫造粒线上造粒吗?

不。湿气会导致熔融物中产生气泡和颗粒开裂;必须通过热风或离心脱水进行干燥。

为什么颗粒会变色?

在塑料泡沫造粒生产线上,可能的原因包括挤出温度过高(塑料降解)、原材料污染或过滤器堵塞。检查温度控制并清理杂质。