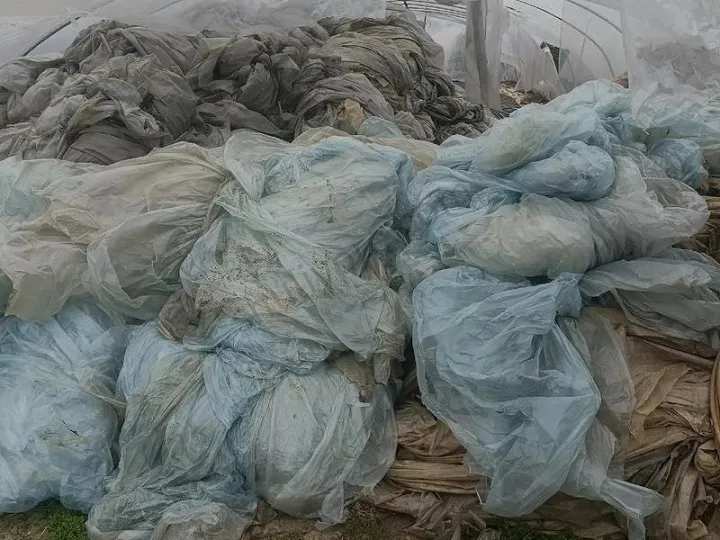

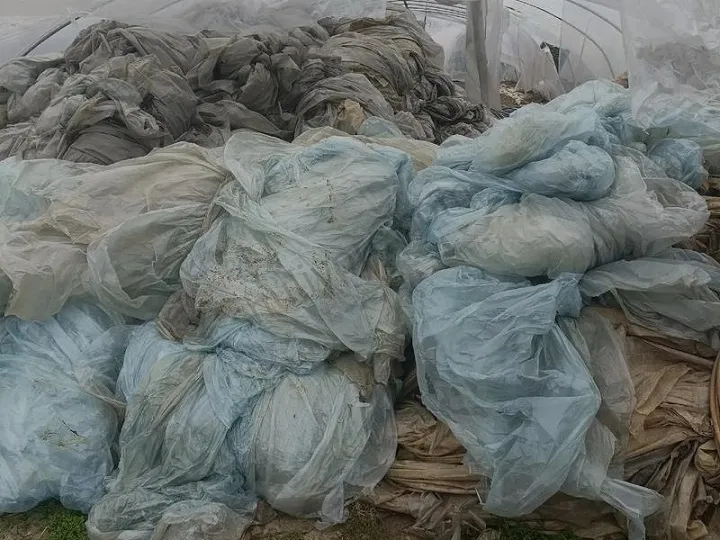

Actualmente, el tema de cómo tratar con el film plástico reciclado está recibiendo cada vez más atención. Las películas plásticas se pueden encontrar en todas partes de nuestra vida diaria, desde las bolsas de supermercado, el embalaje exprés, hasta el acolchado agrícola. Si bien aportan comodidad a nuestras vidas, también son una fuente importante de "contaminación blanca" porque son difíciles de degradar.

Diferentes tipos de films plásticos

La película de plástico, como un producto de película procesado a partir de materias primas plásticas, es rica y diversa, y se puede dividir en materia prima, proceso de producción, uso funcional y otras dimensiones.

Desde el punto de vista material, existen polietileno (PE), polipropileno (PP), cloruro de polivinilo (PVC) y otros tipos comunes, con diferentes materiales para proporcionar su resistencia a la temperatura, flexibilidad, barrera y otros rendimientos diferenciados.

En términos de funciones y escenarios de aplicación, cubren una amplia gama de tipos como embalaje, agrícola, antiestático, degradación, etc., para satisfacer las necesidades de diferentes campos como la conservación de alimentos, el cultivo agrícola y la protección electrónica.

Además, las diferencias estructurales entre la película de una sola capa y la película compuesta de múltiples capas también presentan diferentes ventajas en términos de costo y rendimiento integral.

Estos diversos tipos de película plástica, por virtud de sus respectivas características, han penetrado ampliamente en la industria, la agricultura, la vida diaria y otros escenarios, convirtiéndose en un material indispensable en la producción y la vida modernas.

Significado de tratar con film plástico reciclado

- Aliviar la Contaminación Blanca: Reciclar películas de plástico evita que permanezcan en el medio ambiente natural, reduciendo el daño al suelo, cuerpos de agua y ecosistemas (por ejemplo, la ingestión por parte de animales y la degradación de la estructura del suelo).

- Conservación de Recursos Naturales: Los plásticos reciclados reemplazan parte de las materias primas basadas en petróleo, reduciendo el consumo de recursos fósiles y aliviando la dependencia de recursos no renovables.

- Reducir el consumo de energía y las emisiones de carbono: Producir plásticos reciclados ahorra entre un 30% y un 50% más de energía que los plásticos vírgenes, al tiempo que reduce las emisiones de dióxido de carbono para apoyar los objetivos de neutralidad de carbono.

La importancia de tratar con film plástico reciclado, desde mitigar la contaminación blanca hasta conservar recursos y reducir las emisiones de carbono, subraya la necesidad de un marco de reciclaje sólido.

Sin embargo, ¿cómo tratar con película de plástico reciclado?

Solución de máquina de reciclaje de film plástico

En cuanto a cómo tratar con film plástico reciclado, la línea de pelletizado de film plástico es una solución viable para procesar materiales de film reciclado.

La línea de reciclaje de film plástico Shuliy ofrece una solución confiable para el procesamiento de todo el proceso, gracias a una configuración técnica sistemática.

Paso 1: maquina trituradora de plastico

Un potente triturador tritura mantillo retorcido, film de embalaje, etc., en piezas uniformes.

Paso 2: Máquina de lavado de película de PE

La línea de limpieza de film plástico elimina la suciedad, el aceite y otras impurezas.

Paso 3 Máquina de deshidratación horizontal

Después de secarse en la máquina secadora de plástico, los desechos plásticos entran en la máquina de pelado y lavado de film PE a través del puerto de alimentación.

Paso 4: Máquina granuladora de película plástica

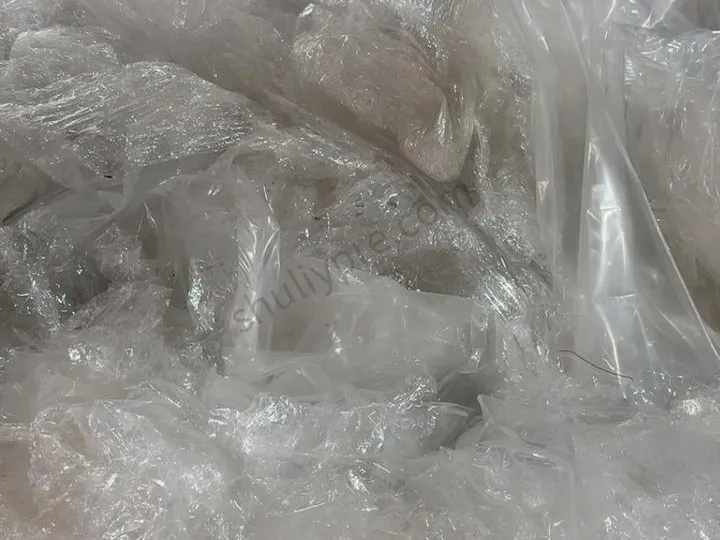

Después de calentar y fundir a alta temperatura, la cabeza de fio se extruye la pasta en tiras. Luego entra en la tanque de enfriamiento para enfriarse.

¿Para qué se puede utilizar el film plástico reciclado?

El film plástico puede ser reciclado y procesado en pellets de plástico, que pueden ser reutilizados en numerosas industrias.

- Industria del embalaje: fabricado en bolsas de compras, bolsas de embalaje de alimentos, bolsas de mensajería y otros tipos de film de embalaje.

- Industria de materiales de construcción: producción de tuberías de drenaje, tuberías de calefacción por suelo radiante, tuberías de protección de cables.

- Industria de fabricación industrial: la producción de bandejas industriales, cajas y piezas de maquinaria

- Industria de bienes de consumo: producción de carcasas de portátiles, juguetes de plástico, carpetas

A continuación se presentan algunos ejemplos de nuestros granuladores de plástico en venta, de los cuales puede leer más información.