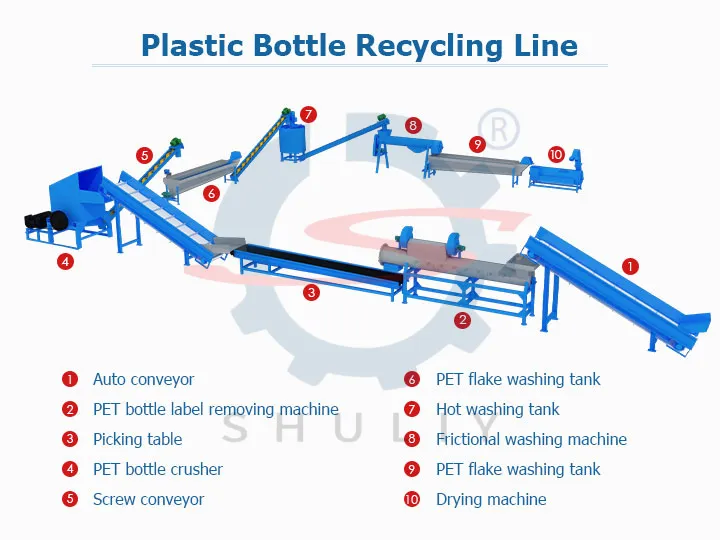

La línea de reciclaje de botellas de plástico es un conjunto completo de equipos para convertir botellas de plástico desechadas en escamas de botellas de PET de alta calidad, lo que puede realizar eficazmente el reciclaje de botellas de plástico desechadas.

Shuliy Machinery es un proveedor profesional de maquinaria de reciclaje de plástico, y podemos personalizarla según sus necesidades. Bienvenido a contactarnos.

Introducción a la línea de reciclaje de botellas de PET

Nuestra línea de reciclaje de botellas de PET convierte botellas de plástico desechadas en copos de PET a través de una máquina quitaetiquetas, un triturador, un tanque de lavado en caliente, un tanque de lavado por fricción y una máquina de secado. Esta línea juega un papel crucial en la promoción de la sostenibilidad ambiental al reducir los desechos plásticos y conservar recursos.

Shuliy Machinery tiene varios tipos de máquinas para triturar y lavar botellas de PET, y toda la línea se puede personalizar. Bienvenido a visitar nuestra fábrica.

Video de funcionamiento de la máquina de reciclaje de botellas de plástico

Este video trata sobre esta línea de reciclaje de botellas de PET en acción, mostrando cómo se procesan las botellas de desecho en copos de plástico.

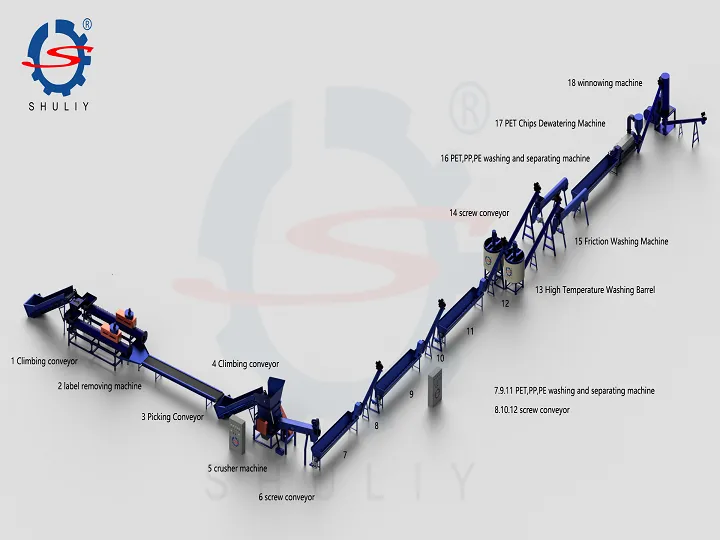

Flujo del proceso de la línea de reciclaje de botellas de plástico

Retirada de etiquetas – trituración – separación de tapones – lavado – secado – almacenamiento

- En primer lugar, si la materia prima está empaquetada como un paquete de botellas, una baler de plástico separará las botellas y luego las enviará a una máquina de eliminación de etiquetas de botellas de plástico a través de un transportador de banda..

- En segundo lugar, la selección manual en la línea de reciclaje de botellas PET es un paso importante para seleccionar botellas de otros colores y botellas que aún tienen etiquetas para mantener la pureza del producto terminado.

- Después de eso, la trituradora triturará estas botellas de PET en copos, y luego se enviarán al tanque de lavado de copos de PET para eliminar las impurezas y las tapas de las piezas.

- A continuación, el tanque de agua caliente y el tanque de lavado por fricción están allí para limpiar aún más los copos.

- Si tiene requisitos más altos para la calidad del producto final, puede decidir las cantidades de estos tanques de lavado.

- El último paso de la línea de reciclaje de botellas de plástico es que la máquina de secado desagua estos copos de PET.

Video de la máquina de reciclaje de botellas de plástico en operación en vivo

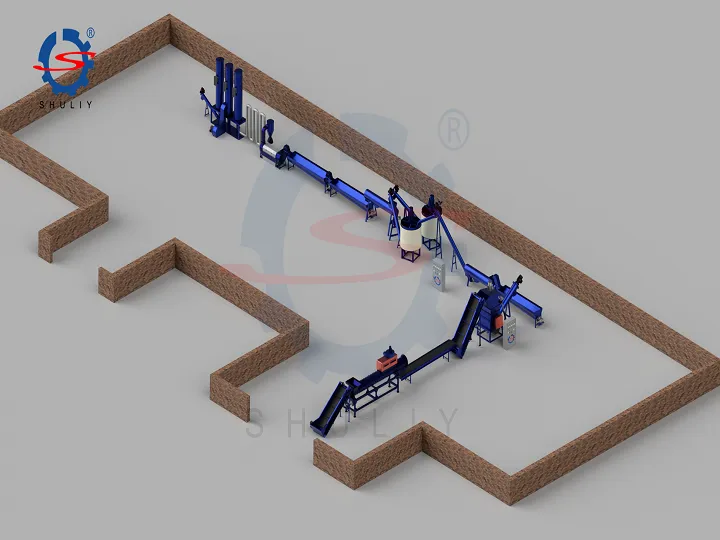

La lavadora trituradora de botellas de PET se puede adaptar a su presupuesto y al tamaño de su planta, así que no dude en contactarnos. Podemos recomendarle la línea de reciclaje de botellas de plástico adecuada para usted.

Materias primas y productos terminados de la línea de producción de escamas de rPET

Materias primas

Los materiales principales de una línea de producción de escamas de rPET son botellas de PET usadas, generalmente compradas en fardos compactados. Estas botellas provienen de diversas fuentes, incluyendo envases de bebidas, botellas de agua mineral, botellas de refrescos carbonatados, botellas de aceite de cocina, botellas de condimentos y otros envases de residuos hechos de PET. A menudo conservan etiquetas, tapas y pueden tener líquidos residuales o manchas.

Los materiales mencionados arriba no son todos los materiales reciclables que se pueden utilizar en la planta de reciclaje de botellas de PET. Si desea consultar sobre los materiales que tiene, puede dejarnos un mensaje.

Productos Terminados

El producto terminado principal de la línea de reciclaje de botellas de PET son las escamas de PET, que sirven como materia prima clave para la producción de productos de PET reciclado. Estas escamas se pueden utilizar directamente para fabricar fibras de poliéster para textiles como ropa, alfombras y materiales de acolchado. También permiten la producción de láminas de PET para cajas de embalaje y productos de burbujas, y pueden ser reinyectadas en nuevas botellas de PET para lograr un reciclaje circular del embalaje de bebidas.

Máquinas principales para la línea de reciclaje de botellas de plástico

Abridor de balas de plástico para botellas de PET

Desempaquetar y aflojar fardos de botellas de PET usadas que están fuertemente comprimidos.

La máquina utiliza cuchillas giratorias para romper las cintas del fardo y separar las botellas agrupadas, convirtiéndolas en individuales sueltas para un procesamiento posterior.

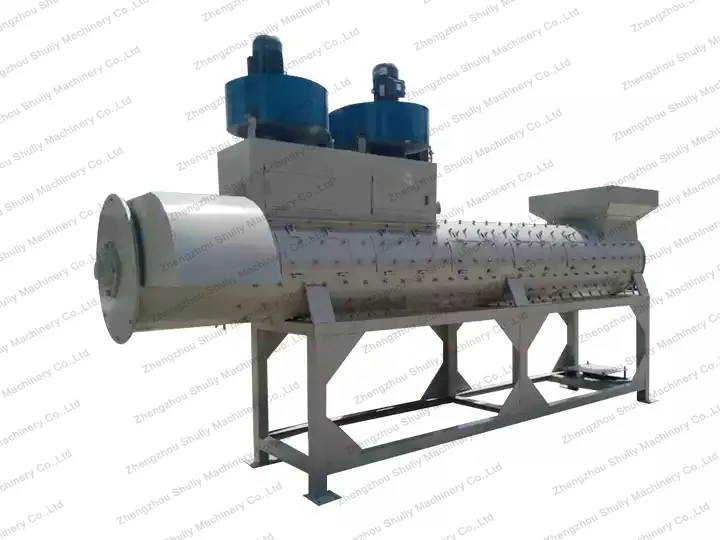

Criba de vaso para reciclaje de botellas de PET

El tamiz rotativo para la línea de reciclaje de botellas de PET sirve para filtrar impurezas finas de los fragmentos de botellas de PET.

Utiliza un tambor rotatorio con pantallas en malla para separar contaminantes pequeños como arena, trozos de papel y restos de tapas de copos de PET triturados.

Máquina para quitar etiquetas de botellas de plástico

La máquina suele estar equipada con un dispositivo de cuchilla ajustable y puede manejar diferentes tipos de botellas, como botellas de agua mineral y botellas de bebidas, así como una amplia gama de materiales, como etiquetas de papel y etiquetas de película de PVC/PE.

La máquina en la línea de lavado de botellas de PET opera de manera estable y tiene una tasa de despegado del 98%, ahorrando mano de obra.

Máquina de trituración de botellas PET

El sistema está diseñado para triturar botellas de plástico recicladas en trozos pequeños. La trituradora de botellas de PET es un equipo importante en la línea de reciclaje de botellas de plástico.

Tanque separador de PP y PE

Se utiliza para separar tapas de botellas de PP o PE de las escamas de PET. Este proceso da como resultado escamas de botellas de PET puro para su posterior reciclaje.

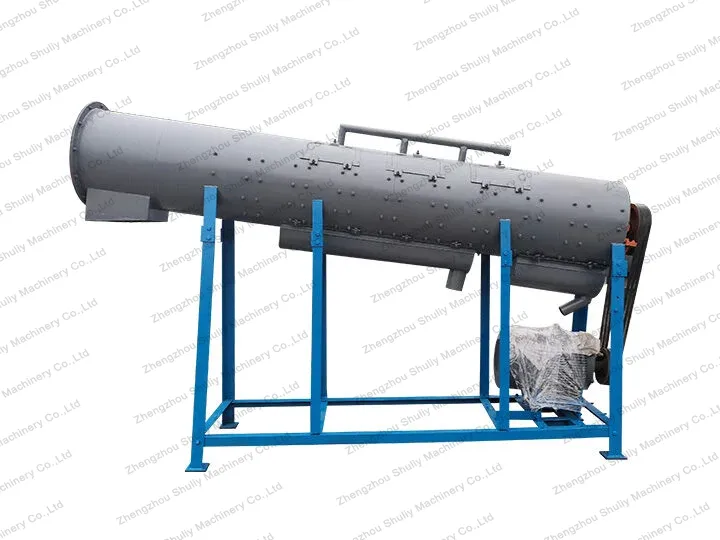

Caliente Tanque de lavado

Esto se logra agregando álcali industrial al lavado caliente en agua a alta temperatura, eliminando así la grasa de la superficie de las escamas de las botellas de PET y haciéndolas más limpias y transparentes.

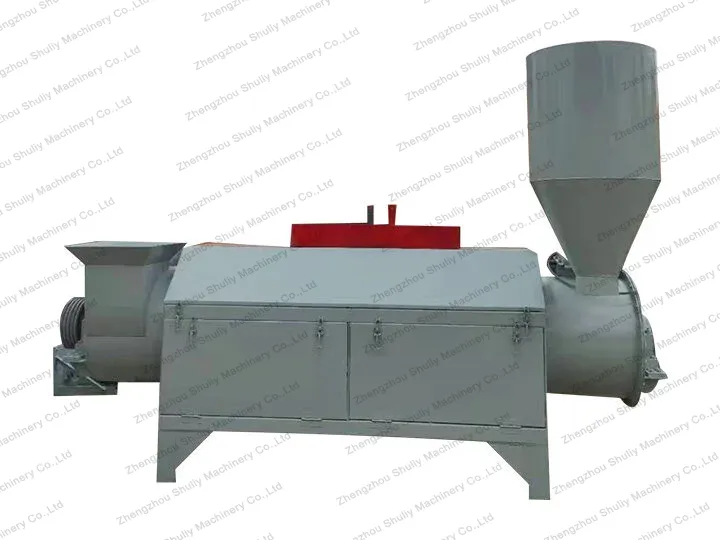

Máquina de lavado por fricción

Las botellas se frotan y limpian para eliminar cualquier residuo de arena, vidrio, metal, polvo de papel o similares en la superficie de la botella.

Máquina de lavado de botellas de PET

Un enjuague con agua fría de varias etapas elimina el agua alcalina industrial y las impurezas de la superficie de las escamas de las botellas, haciéndolas más limpias y libres de contaminación.

Máquina secadora de plástico

La rotación de alta velocidad de la máquina elimina el agua de los copos de la botella, lo que da como resultado copos secos y limpios que se pueden almacenar directamente en bolsas.

La línea de lavado final de botellas PET se puede ajustar de manera flexible según los requisitos de calidad, así que no dude en ponerse en contacto con nosotros con sus ideas y requisitos para que podamos diseñar una línea de reciclaje que beneficie a su planta de reciclaje de botellas PET.

Parámetro de la máquina de reciclaje de botellas PET

| Artículo | Detalles |

| Criba de vaso para reciclaje de botellas de PET | Longitud: 4,5 m Ancho: 1.5 m Potencia del motor: 7.5 kW Grosor de la pared exterior: 8 mm Cuchilla: 10 mm |

| Abridor de balas de plástico para botellas de PET | Longitud: 4.0 m Ancho: 1.5 m Altura: 2.8 m Potencia del motor: 7.5 + 2.2 kw |

| Máquina para quitar etiquetas de botellas de plástico | Modelo: SL-600 Potencia: 11KW+3KW Capacidad: 1-1,2t/h Tamaño: 4000*1800*1600mm Peso: 1500kg |

Los parámetros anteriores son solo un ejemplo, ofrecemos diferentes tamaños de máquinas. Si desea obtener información más detallada, por favor deje un mensaje en nuestro sitio web y nos pondremos en contacto con usted a tiempo.

Ventajas de la línea de reciclaje de botellas de plástico

- Automatización y operación continua: desde el desensamblaje del paquete de botellas hasta la eliminación de etiquetas, aplastado, lavado y secado, todo el proceso está conectado por cintas transportadoras y otros equipos para minimizar la intervención manual y mejorar la eficiencia del procesamiento.

- Producto de alta calidad: Máquina de eliminación de etiquetas combinada con selección manual de color, eliminando efectivamente los residuos de etiquetas y botellas de color extraño, y con múltiples procesos de limpieza para garantizar la pureza de los productos terminados.

- Personalización y flexibilidad: El número de tanques de limpieza en la línea de lavado de botellas de PET se puede aumentar o disminuir de forma independiente para diferentes requisitos de pureza. El color de la máquina también se puede personalizar según los requisitos del cliente.

Preguntas frecuentes sobre la línea de lavado de botellas de PET

¿Es rentable el negocio de la planta de lavado de botellas de PET?

Según las estadísticas, las botellas de plástico se pueden vender a más de $500 la tonelada después de un proceso sencillo, a un coste de más de $200. Por tanto, el negocio del reciclaje de botellas de plástico es muy rentable.

Shuliy Machinery tiene una planta completa de lavado de botellas de PET para ayudarte a iniciar tu propio negocio. La inversión no es muy grande. La operación es relativamente simple, y las ganancias son considerables cuando los materiales son abundantes.

Salida de la máquina de trituración y lavado de botellas de PET

Podemos suministrar lavadoras trituradoras de botellas de PET con producciones que van desde 500 kg/h hasta 3000 kg/h.

Para líneas de reciclaje de botellas de plástico de mayor o menor capacidad, contáctenos para personalizarlas.

¿Cuántos trabajadores necesito para operar la línea de producción de escamas de rPET, y qué nivel de habilidad se requiere?

La mano de obra es un costo operativo clave. Para una línea de producción de 1,000 kg/h de escamas de rPET estándar, normalmente necesitará de 3 a 5 trabajadores: uno para alimentar el material, 2-3 para clasificación manual y uno para supervisar la parte trasera y el embalaje. El sistema de control es centralizado y fácil de usar. Nuestros ingenieros brindan 1-2 días de capacitación práctica en el sitio, asegurando que su equipo pueda operar toda la línea de producción de escamas de rPET de manera competente.

¿Cuáles son las principales piezas de desgaste, cuál es su vida útil y son fáciles y económicas de reemplazar?

Las principales piezas de desgaste son las cuchillas del triturador y los cuchillos del removedor de etiquetas. Su vida útil depende de la limpieza de su material de entrada, pero generalmente dura varios meses. Nuestro triturador está diseñado para cambios rápidos de cuchillas, y podemos suministrar una máquina profesional de afilado de cuchillas para que pueda reafilarlas usted mismo, reduciendo drásticamente los costos de reemplazo. Garantizamos un suministro a largo plazo de todas las piezas de repuesto originales a precios justos.

¿Cuál es el tiempo total desde realizar un pedido hasta que la planta esté operativa en mi fábrica?

El cronograma total del proyecto consta de tres fases principales:

1. Fabricación: Normalmente de 45 a 90 días, dependiendo de la complejidad de la línea.

2. Transporte marítimo: Depende de su ubicación geográfica.

3. Instalación y puesta en marcha en el sitio: Generalmente toma de 15 a 30 días.

Proporcionaremos un diagrama de Gantt detallado del proyecto para que tenga una línea de tiempo clara para cada etapa.

¿Proporcionan instalación y capacitación? Mis trabajadores no tienen experiencia previa.

Sí, esto es una parte fundamental de nuestro servicio y una ventaja clave. Enviamos ingenieros experimentados a su sitio para supervisar la instalación completa de la planta de reciclaje de PET, poner en marcha el equipo y brindar capacitación práctica y completa para sus operadores y personal de mantenimiento. Continuamos hasta que la planta de reciclaje de PET funcione sin problemas y produzca productos calificados. Entregamos un sistema completamente operativo, no solo un conjunto de máquinas.

¿Cuál es el período de garantía y qué sucede si una máquina falla después de que expira la garantía?

Ofrecemos una garantía estándar de un año en todas las piezas contra defectos de fabricación, vigente desde la fecha de aceptación final. Más importante aún, ofrecemos soporte técnico de por vida. Incluso después del período de garantía, puede contactarnos en cualquier momento para solucionar problemas remotos mediante videollamada. Si se requiere servicio en el sitio, podemos enviar un ingeniero (a costo) y garantizamos un suministro a largo plazo de todas las piezas de repuesto. Nuestro objetivo es ser su socio a largo plazo en el éxito.