Une ligne de lavage de recyclage de film plastique, également connue sous le nom de machine à laver les films PE, broie les déchets plastiques en petits morceaux, puis les lave et les sèche. La ligne de lavage de recyclage plastique est adaptée à tous les types de plastiques recyclables de valeur économique tels que le PP, le PE, le PET, le HDPE, le PVC, le LDPE et d'autres déchets plastiques.

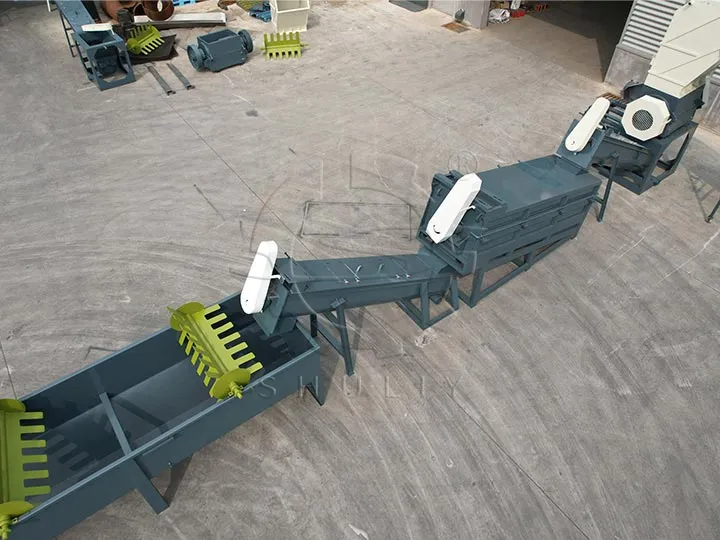

Une ligne de lavage pour le recyclage des plastiques se compose de plusieurs machines, comprenant principalement une machine de broyage de plastique, un bac de rinçage, une machine de séchage de plastique, un bac de stockage, et ainsi de suite.

Qu'est-ce qu'une ligne de lavage pour le recyclage des films plastiques ?

La machine à laver les films en plastique PE est un équipement spécialisé pour le nettoyage des films en PE (polyéthylène), principalement pour le processus de recyclage des déchets de films en PE lors des étapes de nettoyage. Elle peut efficacement éliminer la saleté, les impuretés, les produits chimiques résiduels, etc., de la surface du film, afin de le ramener à un état propre, pour un recyclage et une réutilisation ultérieurs.

Cette machine de lavage de film PE a une haute efficacité de production et un bon effet de nettoyage. L'humidité du plastique après séchage est inférieure à 5 %.

Processus de production de la ligne de lavage de recyclage des plastiques.

Le processus de production d'une machine à pelletiser des films plastiques est un processus systématique conçu pour nettoyer et traiter les plastiques usagés, les rendant adaptés à la réutilisation.

| NON | Processus | Machine | Description |

| 1 | Broyer le film plastique en petits morceaux | Machine de broyage du plastique | La machine à broyer le plastique coupe les déchets de film plastique en petits morceaux d'environ 10 à 20 millimètres de taille et les déplace vers la machine suivante. |

| 2 | Transporter les morceaux de film plastique jusqu'au réservoir de rinçage | Convoyeur à vis | Installé sur la machine à broyer le plastique pour le transport des matériaux |

| 3 | Laver les copeaux de film plastique | Réservoir de lavage | Éliminer les débris du film plastique mélangé à de la saleté et des morceaux de bois. Si le matériau est trop sale, ajouter plus de réservoirs de rinçage. |

| 4 | Sécher le film plastique | Machine de séchage du plastique | Machine de séchage du plastique utilisant la force centrifuge pour éliminer l'eau du film. |

| 5 | Stocker les films et les sacs secs | Bac de stockage | Utilisé pour stocker des films plastiques propres et secs comme matière première pour les machines de granulation plastique |

Vidéo de fonctionnement de l'usine de lavage de plastique

Le principe de fonctionnement des machines de lavage de film PE combine généralement force mécanique, lavage à l'eau, chauffage et nettoyage chimique.

Cette vidéo porte sur la ligne de granulage de plastique filmée sur le terrain. Elle décrit comment fonctionne l'usine de lavage des plastiques recyclés, y compris un convoyeur à bande, une machine de lavage de plastique, et un broyeur de plastique.

Machines principales de la machine de lavage de film PE

La machine à laver les films PE est la combinaison d'équipements clé pour convertir les déchets de films plastiques (tels que les films agricoles en PE, les films d'emballage en PP) en matériaux recyclés propres. Elle comprend principalement cinq systèmes : alimentation et transport, prétraitement par broyage, nettoyage en profondeur, déshydratation et séchage, granulation et refroidissement. Grâce à la force mécanique, au lavage à l'eau, au chauffage et aux additifs chimiques de manière synergique, elle permet d'éliminer la saleté et de recycler les ressources.

Machine de broyage et de déchiquetage en plastique

Les rouleaux ou grandes pièces de film plastique sont broyés en morceaux de 5 à 10 cm pour un nettoyage et une fusion ultérieurs.

Machine à laver en plastique

Élimine la saleté, l'encre, la boue et d'autres impuretés des copeaux plastiques par de l'eau chaude, du détergent et une agitation mécanique.

Machine à sécher en plastique

Le convoyeur de déshydratation dans la machine de lavage de film PE sépare l'eau du film plastique par force centrifuge.

Ci-dessus se trouve la machine de lavage de film PE. Mais notre usine fournit également des équipements de granulation de film plastique.

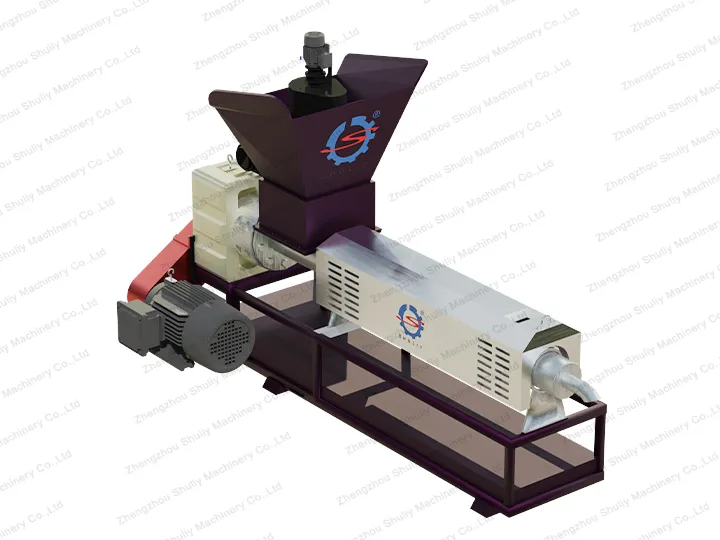

Après que le film plastique usagé a été broyé et nettoyé, il est chauffé et fondu par l'extrudeuse à vis, extrudé à partir de la tête d'extrusion en fines bandes, dans le réservoir d'eau pour le refroidissement et la durcissement, puis coupé en granulés par le granulateur.

Machine de granulation de film plastique

Le film plastique nettoyé est fondu en une pâte à haute température, puis le plastique fondu est extrudé en bandes fines à travers le moule.

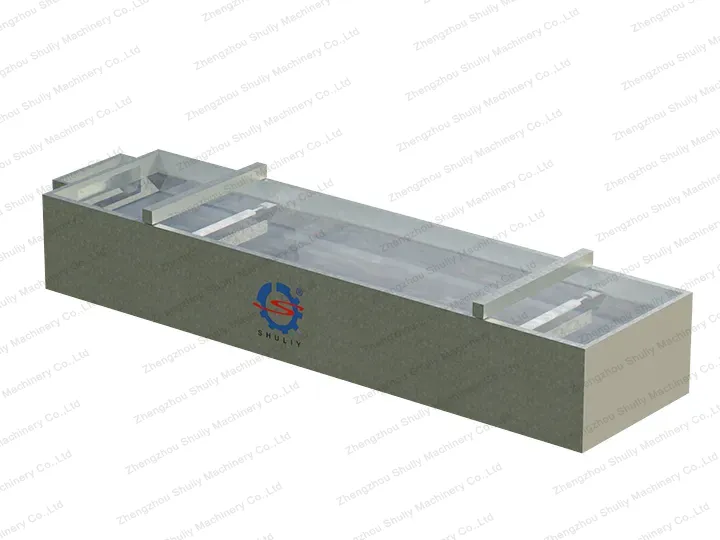

Cooling tank

Refroidissement rapide et mise en forme de la bande de plastique extrudée, la température de l'eau est contrôlée entre 20 et 30 ℃, pour éviter que les granulés ne collent.

Machine de découpe de granulés en plastique

Coupez les bandes fines refroidies en granulés de taille uniforme.

Bac de stockage de granulés plastiques

Il peut fournir un espace relativement fermé pour le matériau afin d'éviter que les particules ne soient polluées par l'environnement extérieur (comme la poussière, l'humidité, etc.) et de protéger la qualité du matériau.

La configuration exacte de la machine de recyclage de sacs tissés peut être ajustée pour répondre à vos besoins. Si vous en avez besoin, vous pouvez nous contacter à tout moment.

Application de ligne de lavage de plastique

Les principaux domaines d'application de nos lignes de lavage de recyclage des plastiques sont :

- Films agricoles

- Film d'emballage

- Film étirable

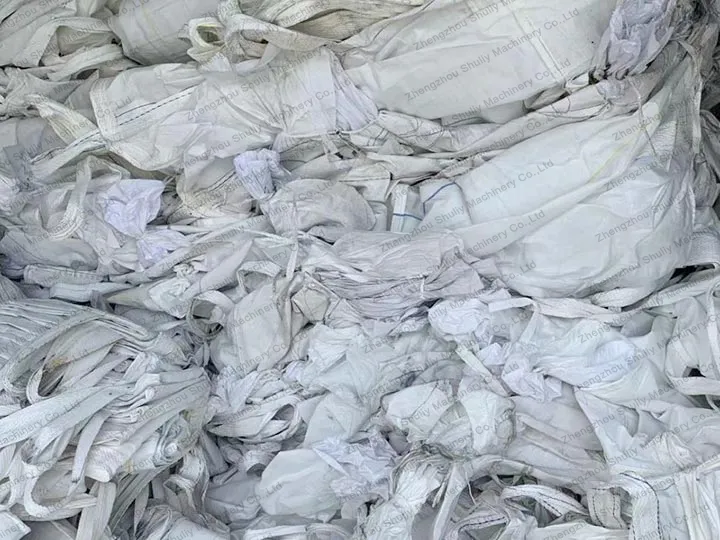

- Sacs PP (grands sacs, sacs en raphia)

- Bouteilles PET

- Boîtes en plastique pour fruits, légumes et bouteilles

- Tous les types de plastiques rigides

- Boucliers en plastique

- Boîtiers d'appareils

- Contenants et seaux en plastique

- Cadres de fenêtres en plastique PVC

Caractéristiques de la ligne de lavage pour le recyclage des films plastiques

- La ligne de lavage plastique peut être conçue en fonction du degré de salissure de vos matières premières pour garantir la qualité du produit final.

- La ligne de lavage de recyclage de films plastiques fonctionne en conjonction avec le travail de granulation ultérieur pour fabriquer des granulés de plastique à partir de films plastiques et de sacs tissés usagés.

- Notre ligne de lavage plastique est facile à utiliser et consomme peu.

- L'usine de lavage de plastique après séchage a une teneur en humidité inférieure à 5 %.

Mettre en place une usine de lavage de plastiques

Cette ligne de recyclage et de lavage de films plastiques est une solution intégrée conçue pour transformer les déchets de films plastiques en matières premières réutilisables. Elle intègre plusieurs unités fonctionnelles pour former un processus de production rationalisé qui gère efficacement divers types de films plastiques usagés, tels que les films plastiques agricoles, d'emballage et industriels.

Nos lignes de lavage de recyclage de films plastiques sont conçues pour retraiter les déchets plastiques. Nous pouvons également fournir des solutions de nettoyage et de recyclage spécifiques personnalisées en fonction de la nature de la matière plastique brute et de vos besoins d'application. N'hésitez pas à laisser un message sur notre site Web si nécessaire.

Questions fréquentes sur la machine de lavage de film PE à vendre

Qu'est-ce qui cause le nettoyage incomplet des machines de recyclage des films plastiques ?

Température de l'eau insuffisante ou temps de lavage trop court, ou agitation mécanique insuffisante.

Comment résoudre le problème des granulés plastiques agglomérés après séchage ?

Réduisez la température de l'air chaud à 80-90°C et augmentez la fréquence de mélange des matériaux.