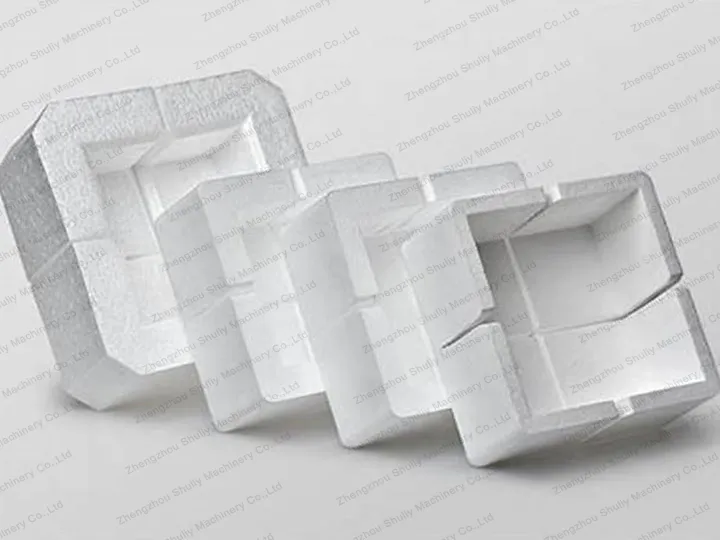

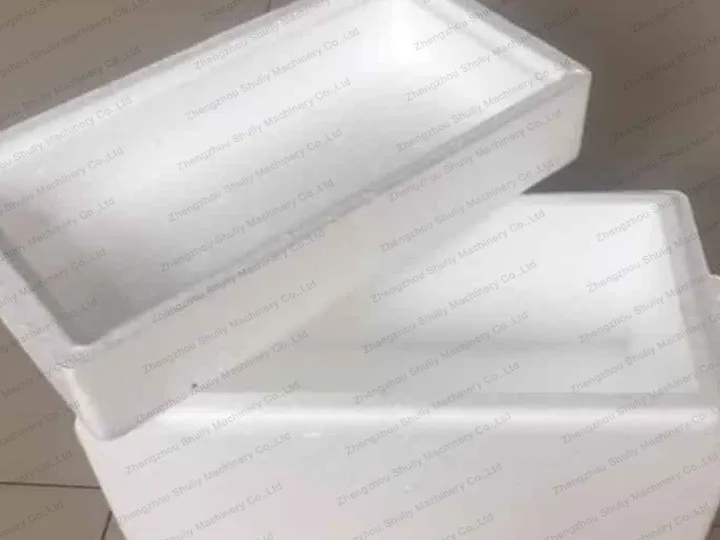

La machine à granuler EPS est adaptée à la régénération et à la granulation de l'EPS et d'autres mousses. Elle est principalement utilisée pour la régénération et la granulation des boîtes en mousse, des panneaux en mousse et des protections d'angle en mousse. Ce type de granulés plastiques recyclés peut être utilisé pour fabriquer toutes sortes de fournitures de bureau, de jouets, de coques d'appareils électroménagers, etc.

Introduction à la machine de granulation EPS

La machine à pelletiser EPS est une machine spéciale pour broyer et granuler les déchets de mousse et de coton perlé. Le granulateur EPS a un design raisonnable, un haut degré d'automatisation et une technologie avancée. Les granulés produits sont largement utilisés et en forte demande sur le marché, avec des utilisateurs dans le monde entier !

La machine à pelletiser EPS recycle les déchets EPS en granulés réutilisables par écrasement, fusion, extrusion et pelletisation. Dotée d'un chauffage économe en énergie et de vis durables, elle convient à diverses densités de déchets, soutenant l'économie circulaire dans l'emballage et la construction.

Principe du granulateur EPS

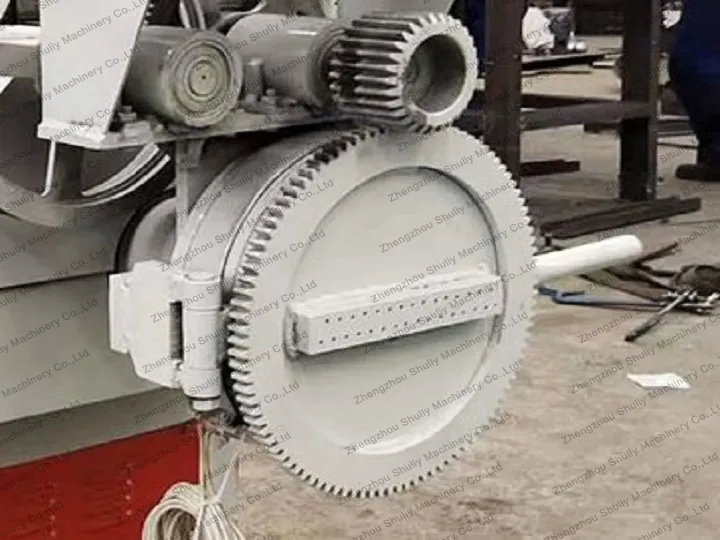

Le principe de la machine à pelletiser EPS est très simple. Le granulateur de mousse utilise un moteur pour entraîner un réducteur afin de pousser le matériau vers l'avant. La mousse est fondue sous l'action d'un dispositif de chauffage externe et devient ensuite des granulés recyclés à travers une série de processus. La machine à pelletiser EPS est la plus importante dans la ligne de granulation de mousse plastique.

Paramètres de la machine de granulation EPS

| Type | 600-800 kg/h | Moteur principal |

| 220 (double réducteur) | 150-175 kg/h | Taille d'entrée |

| 270 (double réducteur) | 200-225 kg/h | 18,5 kW |

| 320 (double réducteur) | 275-300 kg/h | 18,5 kW |

Si vous souhaitez obtenir plus d'informations, veuillez nous laisser un message sur le site web, et nous vous contacterons rapidement !

Principales parties de la machine de recyclage EPS

convoyeur d'alimentation

Il utilise la synergie de la transmission mécanique et du transport de matériaux pour réaliser un transport directionnel des matériaux en entraînant le réducteur par le moteur, qui à son tour entraîne la bande transporteuse, la vis et d'autres parties de transport pour fonctionner.

Tête de fil

La forme interne de la tête de filière permet au plastique à l'état fondu de passer uniformément à travers les trous de la filière pour former une bande de stock de forme spécifique.

Anneau chauffant

Les anneaux chauffants convertissent précisément l'énergie électrique en énergie thermique, fournissant un soutien de température stable pour les équipements industriels.

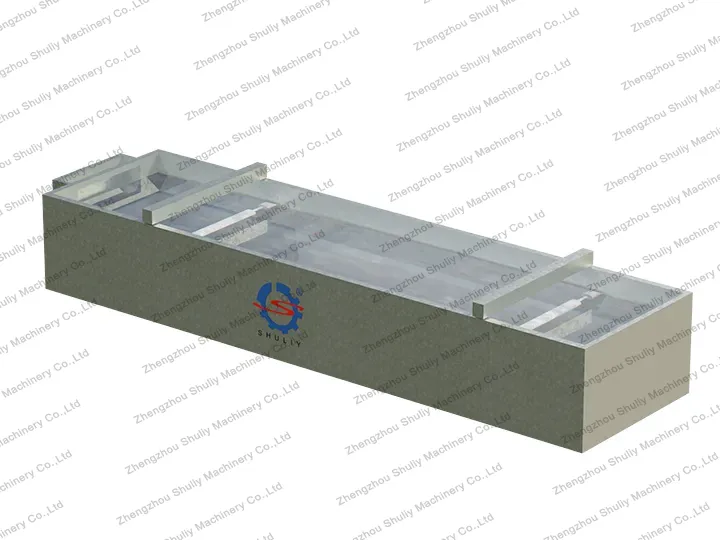

Solution pour la ligne de machine de recyclage de polystyrène

Dans la production industrielle moderne, le fonctionnement synergique d'une machine de pelletisation EPS entière offre des avantages incomparables. Lorsque les différentes parties de la ligne de production de pelletisation EPS, telles que le broyeur, l'extrudeuse de fusion, le pelletiseur, etc., forment un tout organique, le matériau allant de l'entrée de la mousse usagée à la sortie des granulés finis de l'ensemble du processus réalise une connexion sans couture.

Cette machine à pelletiser EPS augmente non seulement la capacité de production de plus de 30 %, mais réduit également l'effort de travail de près de la moitié grâce à un transport automatisé et des opérations intégrées, éliminant ainsi le besoin pour les travailleurs de faire des allers-retours entre plusieurs machines.

Machine de refroidissement en plastique

Il réduit rapidement la température du plastique fondu grâce à de l'eau de refroidissement pour le solidifier et le façonner, évitant ainsi la déformation, les fils ou les écarts dimensionnels causés par une température excessive.

Machine à couper les granulés en plastique

La machine de découpe de granulés en plastique coupe la longue bande en petites particules.

Bac de stockage de granules plastiques

C'est une unité de tampon clé dans le processus de transformation des plastiques, principalement utilisée pour le stockage temporaire des granulés produits.

La configuration spécifique de la ligne de granulation de mousse EPS peut être ajustée en fonction de vos besoins. Si vous avez ce besoin, n'hésitez pas à nous contacter !

Caractéristiques du granulateur de mousse

- L'adoption des machines principales et secondaires pour soutenir la production, la température de chauffage est stable, ce qui améliore efficacement la structure moléculaire du matériau et renforce la perméabilité à l'air, et la qualité des granulés est améliorée !

- L'unité de la machine de granulation EPS est principalement composée d'un concasseur, d'une machine principale et d'une machine de découpe automatique par traction, et la machine principale adopte un dispositif de changement automatique de filet.

- Les barillets à vis de la machine principale et secondaire sont en acier structurel au carbone de haute résistance.

- Le granulateur en mousse adopte un barillet à vis conique, avec une vitesse d'alimentation rapide et un rendement élevé.

Comment faire fonctionner un granulateur de mousse en plastique ?

Il y a deux cercles de chauffage sur la vis supérieure et inférieure du granulateur en mousse, et chaque cercle de chauffage a un interrupteur, qui peut être ouvert et fermé à volonté en fonction de la température requise pour le traitement.

Lorsque le granulateur haute vitesse EPS fonctionne, les barils supérieur et inférieur sont chauffés pendant 20 à 40 minutes, puis prenez un morceau de mousse sur la tête et appuyez légèrement. Si la mousse devient molle et fond, cela signifie que le chauffage du baril a

atteint la température de fonctionnement (environ 180 degrés) et la machine peut être mise en marche.

Dans le travail du granulateur à mousse, la tête de vis inférieure peut ajouter une ou deux couches de filtres de 20-80 mailles ou un autre nombre de filtres approprié selon les besoins (plus la maille du filtre est élevée, plus les impuretés sont propres). Il devrait y avoir plus d'un tamis. Si le travail n'est pas fluide, cela signifie que le tamis est obstrué, et le tamis doit être remplacé à temps.

Machine à granuler EPS exportée vers la Malaisie

Lamachine de pelletisation EPS exportée vers la Malaisiecette fois a été soigneusement conçue et strictement contrôlée, avec une haute efficacité et des performances stables.

Le client en Malaisie a une riche expérience et des besoins clairs dans le domaine du recyclage de la mousse plastique, et notre machine de granulation EPS peut convertir efficacement les déchets de mousse EPS en granulés réutilisables, ce qui répond parfaitement à ses besoins commerciaux en matière de recyclage et de réutilisation des ressources.

Auparavant, l'équipe de vente a gagné la confiance totale du client en fournissant des images et des vidéos détaillées de l'équipement et en répondant rapidement aux questions.

À l'heure actuelle, la machine à pelletiser EPS a été emballée et expédiée avec succès, et nous attendons avec impatience son utilisation en Malaisie pour aider l'industrie locale du recyclage des plastiques à atteindre de nouveaux sommets.

FAQ de la ligne de granulation de mousse EPS

Que faire si la température est trop élevée ou trop basse ?

Trop élevé provoque la carbonisation ; trop bas entraîne une mauvaise formation ou un blocage.

Raisons courantes de blocage de l'extrudeuse ?

Impuretés, contrôle de température inadéquat ou vis usée.

Que se passe-t-il si l'eau de refroidissement est insuffisante ?

Mauvaise formation des granulés, risque de collage ou de déformation.