एक स्टायरोफोम कम्पैक्टर एक विशेष मशीन है जिसे पॉलीस्टायरीन स्टायरोफोम कचरे के मात्रा को कम करने के लिए यांत्रिक दबाव लागू करके डिज़ाइन किया गया है। ढीले फोम को घने ब्लॉकों में संकुचित करके, यह 90% तक की मात्रा में कमी प्राप्त करता है, भारी कचरे को प्रबंधनीय सामग्रियों में बदल देता है ताकि इसे आसानी से संग्रहित, परिवहन और पुनर्नवीनीकरण किया जा सके।

स्टायरोफोम कम्पैक्टर का परिचय

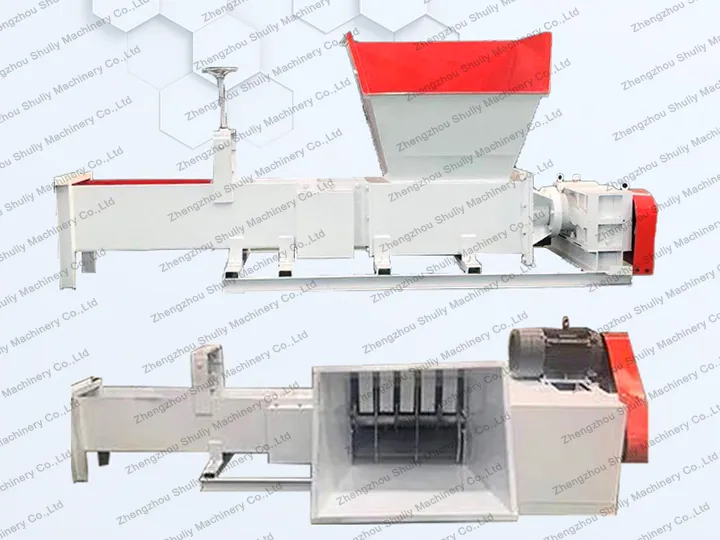

The स्टायरोफोम कंपैक्टर is an industrial equipment that uses mechanical pressure or hydraulic drive to compress EPS foam at room temperature. Different from hot press, which needs to be heated and melted, it relies on physical extrusion to realize volume reduction, and is suitable for temperature-sensitive or waste material processing scenarios that do not require material modification.

स्टायरोफोम कम्पैक्टर का कार्य सिद्धांत

- फीडिंग: ढीला स्टायरोफोम कम्पैक्टर के हपर में डाला जाता है।

- संपीड़न: एक हाइड्रोलिक या यांत्रिक प्रेस उच्च दबाव में फोम को कुचलता है।

- उत्सर्जन: संकुचित फोम घने ब्लॉकों के रूप में निकाला जाता है, जिन्हें आसानी से ढेर किया जा सकता है या पुनर्चक्रण सुविधाओं को बेचा जा सकता है।

पॉलीस्टाइरीन कम्पैक्टर के दो प्रकार

कोल्ड प्रेस के दो प्रकार होते हैं: वर्टिकल कोल्ड प्रेस और हॉरिजेंटल कोल्ड प्रेस। हम आपकी कई आवश्यकताओं को पूरा करने के लिए विभिन्न प्रकार प्रदान करते हैं।

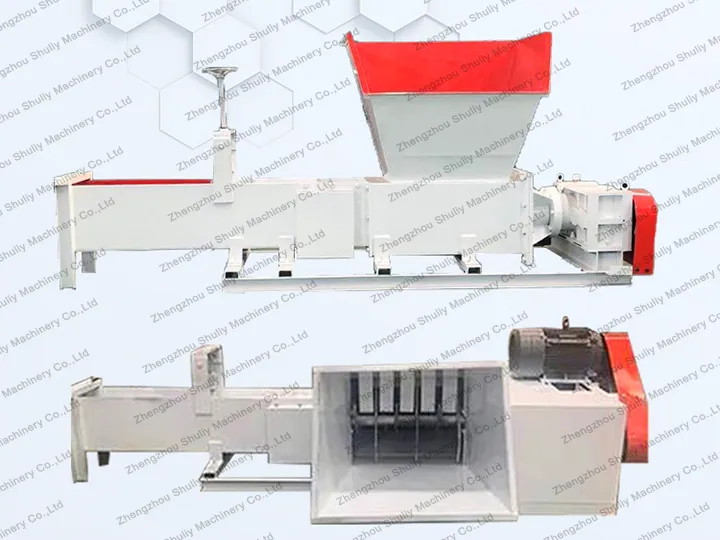

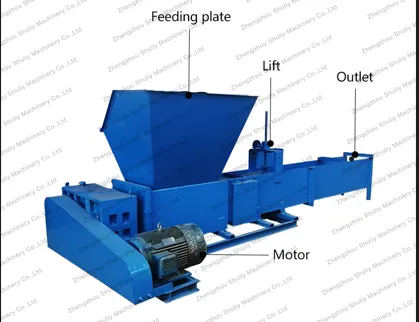

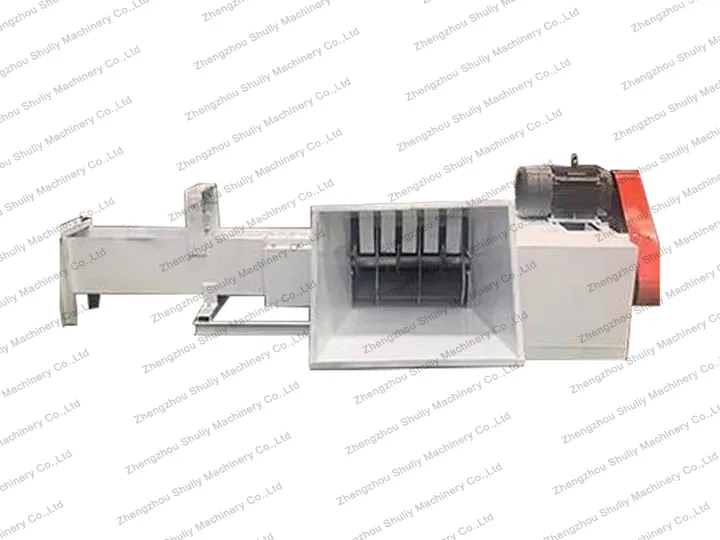

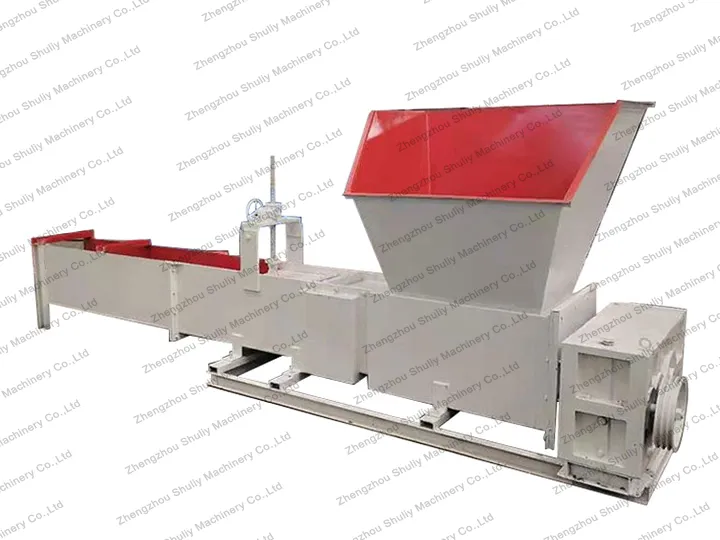

क्षैतिज ईपीएस फोम संकुचन मशीन

संपीड़न कक्ष क्षैतिज रूप से व्यवस्थित होता है, जिसमें इनलेट और आउटलेट पोर्ट क्षैतिज रूप से व्यवस्थित होते हैं।

- हॉरिजेंटल ईपीएस फोम कम्पैक्टर बड़े मात्रा के स्क्रैप (जैसे फोम पैकेजिंग के पूर्ण बक्से) को समायोजित कर सकता है।

- इसका इनलेट सीधे एक क्षैतिज कन्वेयर बेल्ट से जोड़ा जा सकता है। फोम स्क्रैप को बेल्ट कन्वेयर के माध्यम से सीधे क्षैतिज प्रेस में डाला जा सकता है, जिससे मैनुअल हैंडलिंग कम होती है।

- इसके अलावा, यह वर्टिकल मॉडल के गुरुत्वाकर्षण गिरने के कारण सामग्री के असमान संचय से बचाता है।

ऊर्ध्वाधर EPS फोम कम्पैक्टर

संपीड़न कक्ष ऊर्ध्वाधर रूप से व्यवस्थित होता है, और अपशिष्ट सामग्री ऊपर से नीचे की ओर गुरुत्वाकर्षण द्वारा गिराई जाती है।

- वर्टिकल ईपीएस फोम कम्पैक्टर का वर्टिकल कॉम्पैक्ट डिज़ाइन उन परिदृश्यों के लिए उपयुक्त है जहाँ भंडारण क्षेत्र में स्थान सीमित है या तीन-आयामी लेआउट के लिए जहाँ बहु-स्तरीय संयंत्र की आवश्यकता होती है।

- यह एक बंद ऊर्ध्वाधर संपीड़न कक्ष है जिसमें एक धूल निकासी इंटरफेस है जो क्षैतिज मॉडलों की तुलना में धूल के गिरने को कम करता है।

ईपीएस फोम कम्पैक्टर की विशेषताएँ और लाभ

- कम तापमान प्रसंस्करण: पीएस फोम एक गर्मी-संवेदनशील सामग्री है, जो उच्च तापमान पर नरम और विकृत या यहां तक कि पिघलना आसान है। ठंडी प्रेसिंग तापमान परिवर्तन के कारण ईपीएस के आकार में विकृति, सतह दरार या रासायनिक बिगड़ने से बचा सकती है।

- एकसमान और स्थिर दबाव: EPS फोम का घनत्व कम और बनावट ढीली होती है, ठंडी दबाने से एकसमान बल हाइड्रोलिक या यांत्रिक रूप से प्रदान किया जा सकता है ताकि यह सुनिश्चित किया जा सके कि फोम दबाव के तहत एकसमान रूप से ढाला गया है, अत्यधिक दबाव के कारण फोम सेल की दीवारों के टूटने से बचा जा सके।

- सामग्री उपयोग दर में सुधार: ठंडी प्रेसिंग का उपयोग किनारों और स्क्रैप के द्वितीयक प्रेसिंग और पुनर्चक्रण के लिए किया जा सकता है (जैसे, कुचले हुए फोम को ब्लॉकों में ठंडी प्रेसिंग करना), और सामग्री उपयोग दर को 90% से अधिक बढ़ाया जा सकता है।

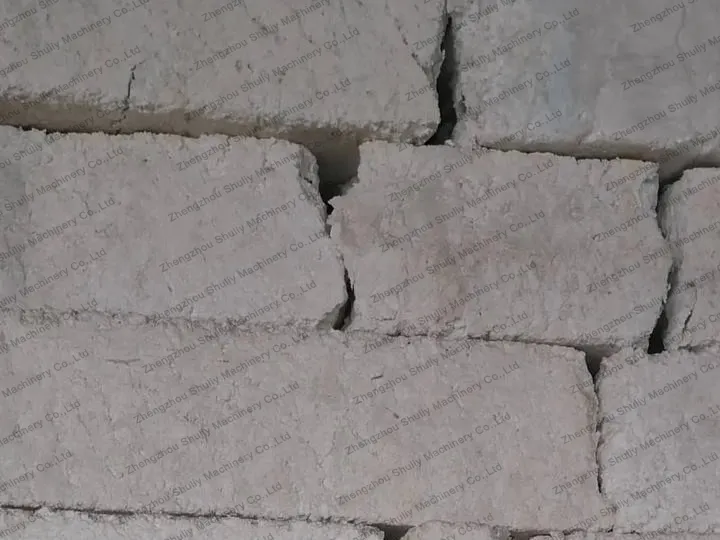

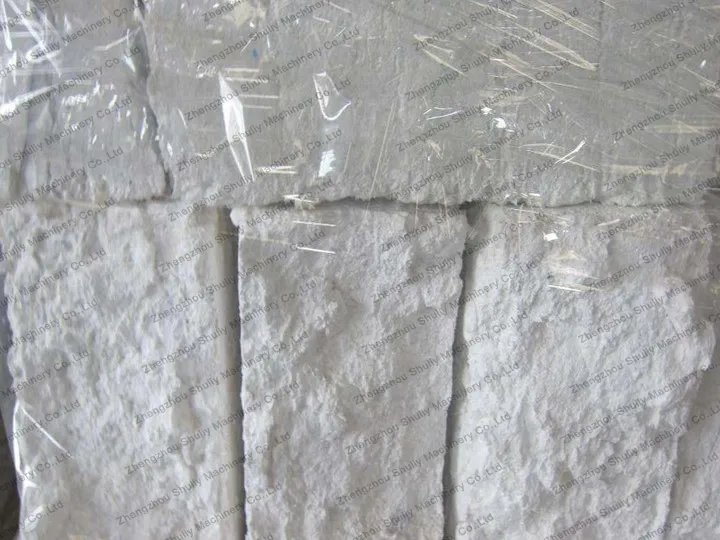

फोम कम्पैक्टर मशीन का अंतिम उत्पादन

ईपीएस फोम कचरे को उच्च दबाव के साथ ठंडे प्रेस द्वारा दबाने के बाद, यह कॉम्पैक्ट और नियमित ब्लॉकों में बदल जाता है, जो ढीले कचरे की तुलना में मात्रा को काफी कम करता है और परिवहन और पुनर्चक्रण के लिए सुविधाजनक होता है।

इस प्रकार का फोम ब्लॉक मूल कुशनिंग प्रदर्शन को बनाए रखता है, इसे सीधे लॉजिस्टिक्स कुशनिंग या बागवानी भराव सामग्री के रूप में उपयोग किया जा सकता है, इसे दूसरी ठंडी प्रेसिंग के बाद नए उत्पादों में भी कुचला जा सकता है, न केवल सफेद प्रदूषण की समस्या को हल करने के लिए, बल्कि उत्पादन की लागत को भी कम करने के लिए, यह परिपत्र अर्थव्यवस्था में फोम संसाधनों के पुनर्चक्रण का मुख्य रूप है।

स्टायरोफोम कम्पैक्टर की कीमत

यदि आपको EPS फोम को प्रोसेस करने के लिए एक पॉलीस्टाइरीन कम्पैक्टर की आवश्यकता है या विभिन्न आकारों के उपकरणों के प्रदर्शन और लागू परिदृश्यों के बारे में जानना चाहते हैं, तो कृपया हमसे एक कोटेशन के लिए संपर्क करने में संकोच न करें।

शुली आपके उत्पादन की आवश्यकताओं के अनुसार अनुकूलित समाधान भी प्रदान कर सकता है (जैसे कि तैयार उत्पाद घनत्व, दबाने की दक्षता, स्वचालन की डिग्री), उपकरण चयन से लेकर प्रक्रिया मापदंडों के कमीशनिंग तक, ताकि आप कुशल उत्पादन और लागत अनुकूलन प्राप्त कर सकें। हम आपकी विशिष्ट आवश्यकताओं के बारे में आपसे संवाद करने और आपको विस्तृत मूल्य उद्धरण और तकनीकी समर्थन प्रदान करने की उम्मीद करते हैं!