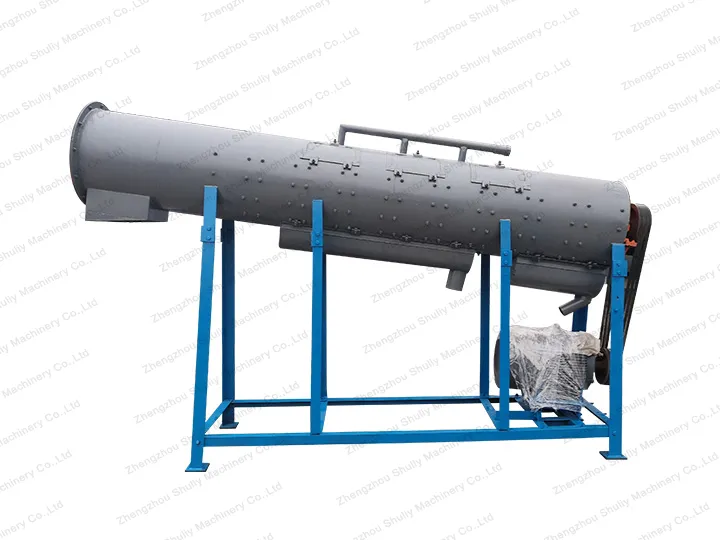

摩擦洗衣机,专为摩擦洗涤塑料回收而设计,对于受污染的塑料片和薄膜非常有效。它可以集成或改装到您的回收造粒和洗涤生产线中。

摩擦洗衣机介绍

摩擦清洁机是一种先进的设备,旨在利用摩擦原理清洁各种材料。它已成为塑料回收、金属加工和纺织制造等行业的必备工具,显著提高了清洁过程的效率和质量。

PET瓶片摩擦洗涤机主要用于PET瓶片的清洗和输送。破碎的瓶片通过螺旋装载机进入摩擦洗涤机。螺旋在电机驱动下旋转,瓶片在叶片的推动下向前移动并被清洁。

摩擦洗衣机是如何工作的?

高速摩擦洗衣机由一个高速转子和可拆卸筛网组成。高速转子确保材料在筛网内“擦洗”和“拍打”。多个喷嘴喷水在筛网上,持续去除杂质和污垢。杂质和脏水随后通过筛孔排出并收集在底部。

塑料摩擦洗衣机以45度角放置,以最大化摩擦并去除杂质和污染物。

塑料瓶洗衣机的过程

摩擦洗衣机的工作原理结合了机械摩擦和水冲洗。机器内部有高速旋转的部件,例如螺旋桨叶片或摩擦板。

步骤 1:摩擦去污处理

当塑料瓶进入机器时,旋转部件驱动下,瓶子之间以及瓶子与摩擦部件之间会产生强烈的摩擦,这可以剥离附着在瓶子表面的各种杂质。

步骤2:水流辅助冲洗和冷却处理

与此同时,机器将注入内部水流,一方面水流有助于冲洗掉被摩擦下来的杂质,另一方面也起到冷却的作用,以防止塑料瓶碎片因摩擦产生的热量而变形或熔化。

塑料摩擦洗涤器结构

- 旋转部件:大多由高强度不锈钢制成,通常是带有特殊图案的螺旋搅拌器或摩擦板。

- 清洗筒:筒通常由厚碳钢或不锈钢制成,具有良好的耐磨性和耐腐蚀性。

- 供水系统:它包含水入口管、喷嘴等组件。水入口管负责将清水引入机器,而喷嘴则以特定的角度和压力喷洒水。

塑料瓶回收线解决方案

通过将摩擦洗衣机与塑料洗衣机和热洗槽结合使用,可以构建一个高效的清洗系统。

在这个系统中,摩擦洗衣机利用强摩擦力去除材料表面的杂质,洗涤槽提供足够的空间进行水冲洗,而热洗槽则利用高温进一步溶解顽固污渍。

这三者相辅相成,可以显著提高清洁效率和清洁度,达到远超单一设备操作的清洁效果。

塑料摩擦洗涤器的特点

- 全拆卸箱体结构,便于整机维护

- 筛网采用不锈钢制造,使用寿命长

- 安装结构简单,设备维护成本低

- 塑料瓶洗衣机配备自动过载保护系统,以最大程度确保设备的安全可靠性

高速摩擦洗衣机可以用于什么?

高速摩擦洗衣机通常用于塑料瓶破碎机之后。它可以用于清洗PP、PE、HDPE、PVC和ABS片。

在各种可回收的废塑料清洗线中,大多数都会应用塑料摩擦洗衣机。该机器的高速洗涤方法使它在塑料瓶洗涤回收线上发挥了重要作用。

高速摩擦洗衣机的成功安装

高速摩擦洗衣机已成功销往多个国家。例如,莫桑比克、印度尼西亚、刚果和南苏丹。

目前,摩擦洗衣机已成功安装在莫桑比克,并且运行良好,帮助莫桑比克工厂回收PET瓶。

根据刚果工厂的反馈,刚果的摩擦洗衣机运行稳定高效,并获得了许多好评。

摩擦洗衣机咨询

我们可以为您的塑料瓶回收线提供完整解决方案:

从原材料研究和分析到应用现场调查,技术方案设计到整体工程布局,从设备生产到整条线的安装和调试,我们为您提供一站式服务,让您安心开展自己的业务。

摩擦洗衣机常见问题解答

如何解决清洁效果差的问题?

①定期检查并更换磨损的摩擦组件;

②清洁喷嘴并调整水流入量。

③根据污垢程度延长清洁时间。

④根据规定的加工能力投料。

排水和过滤系统失效的原因是什么?

①排水管道堵塞;

②排水泵故障。

设备异常运行的原因是什么?

①不稳定的设备安装;

②旋转部件的松动或变形;