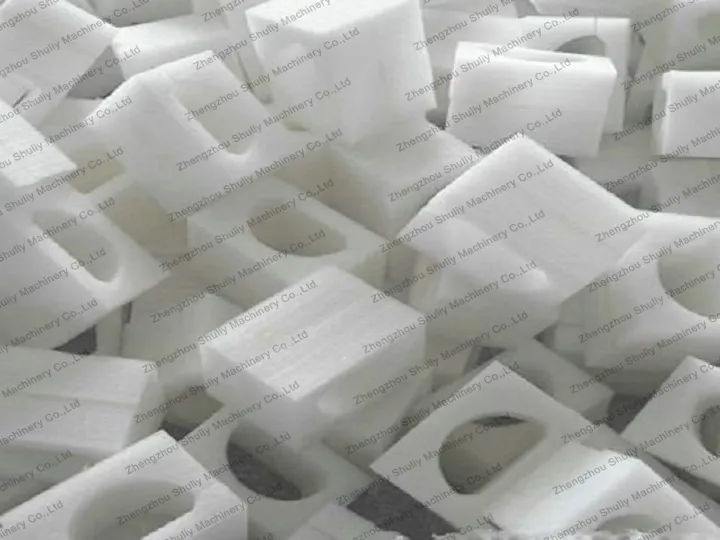

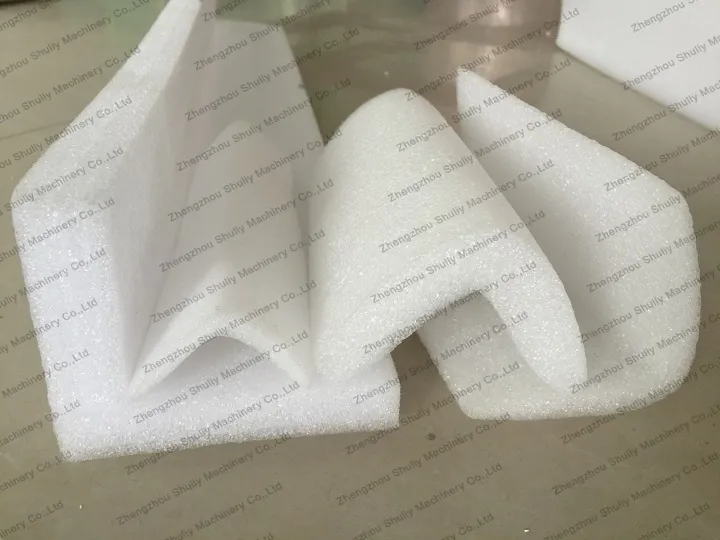

Le pelletiseur EPE consiste à fabriquer des granulés de plastique recyclés à partir de déchets de mousse EPE à travers le processus de concassage, de fusion, d'extrusion, de granulation et de refroidissement.

Vidéo de travail de la machine de pelletisation en polystyrène EPE

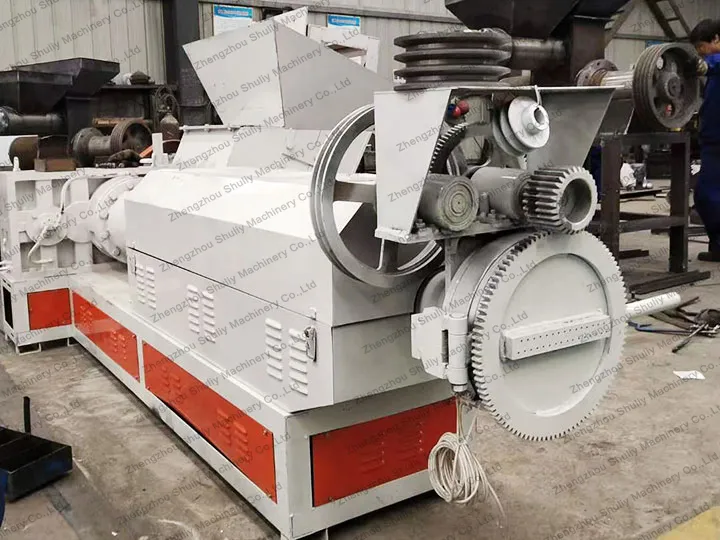

Introduction de la machine à granuler en polystyrène EPE

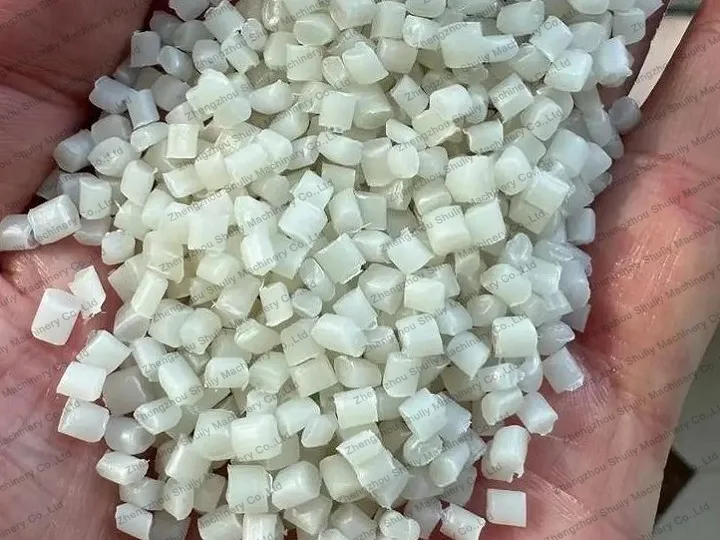

La machine de granulation de polystyrène expansé (EPE), également connue sous le nom de granulateurs de mousse plastique, peut produire des granulés plastiques sans détruire la structure moléculaire d'origine. Les granulés produits sont largement utilisés.

Le granulateur EPE convient à l'extrusion et à la granulation de matières premières en mousse EPE, qui peuvent être utilisées pour la régénération de la mousse EPE. Le granulateur de mousse plastique Shuliy adopte une structure d'échappement pour exclure le gaz produit lors du processus de plastification, ce qui rend les granulés denses et lisses. L'opération de production est très simple et le coût d'investissement est très faible, mais le bénéfice économique est élevé.

Principales pièces de la machine de recyclage de polystyrène

Convoyeur d'alimentation

L'entrée d'alimentation adopte un design à entrée directe de grand diamètre, qui est adapté pour l'alimentation directe de matériaux EPE souples sans pré-broyage, avec une efficacité d'alimentation élevée et une opération pratique.

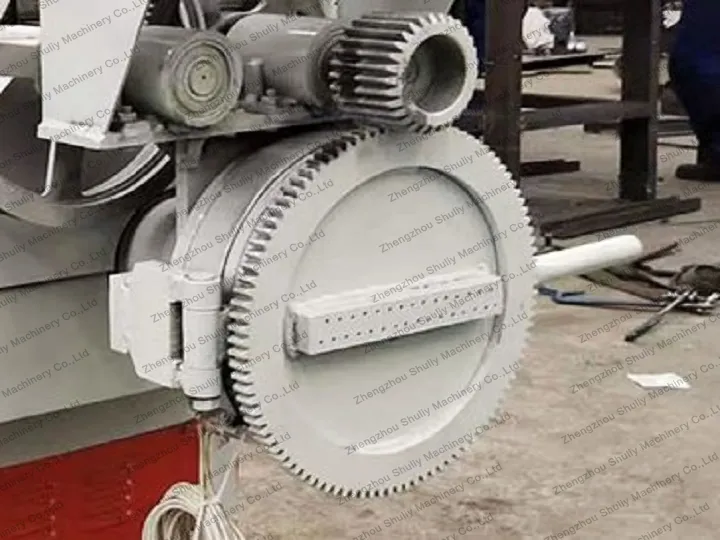

Anneau de chauffage

L'anneau de chauffage sert à faire fondre la mousse et à la convertir en pâte afin qu'elle puisse passer en douceur à travers la tête d'extrusion.

Tête de filière

La tête de filière extrude la mousse fondue à travers ses trous internes en bandes pour une coupe ultérieure.

Paramètres de la machine à granuler en polystyrène EPE

| Article | Détails |

| Machine à fabriquer des granulés | Machine à granulés |

| Réservoir d'eau | Longueur : 4m |

| Machine de découpe de granulés | Power:1.5kw |

Si vous souhaitez en savoir plus, n'hésitez pas à nous contacter !

Processus de ligne de granulation de mousse EPE

Lorsque la machine à pelletiser en polystyrène expansé (EPE) fonctionne, les déchets de mousse EPE sont d'abord introduits dans la machine par le port d'alimentation, puis broyés en petits morceaux par l'unité de broyage.

Ensuite, cela entre dans la partie centrale de la machine de pelletisation, et l'unité de chauffage chauffe les morceaux cassés jusqu'à l'état fondu.

Ensuite, avec la pâte dans la zone de vis de la machine à pelletiser en polystyrène expansé (EPE), la vis est poussée vers le moule pour être extrudée en une longue bande.

La longue bande de matériau dans le réservoir de refroidissement s'est rapidement refroidie et durcie ; enfin, par le pelletiseur, elle a été découpée avec précision en petites particules pour un stockage et un transport faciles.

Méthodes d'opération de la machine de pelletisation en polystyrène EPE

- Il y a deux circuits de chauffage sur la vis supérieure et inférieure de la machine à pelletiser en polystyrène expansé, et chaque circuit de chauffage a un interrupteur, qui peut être ouvert et fermé à volonté en fonction de la température nécessaire au traitement.

- Lorsque le granulateur de mousse fonctionne, chauffez d'abord les fûts supérieur et inférieur pendant 20 à 40 minutes, puis prenez un morceau de mousse sur la tête de la machine et appuyez légèrement dessus. Si la mousse peut devenir molle et fondre, cela signifie que le fût chauffe. a atteint la température de fonctionnement et la machine peut être allumée.

- Ajoutez d'abord une petite quantité de mousse dans la trémie. Si le matériau extrudé a fondu, c'est seulement à ce moment-là qu'une grande quantité de matériau peut commencer à être utilisée. Si la température est jugée trop élevée pendant le travail, vous pouvez couper l'alimentation en chaleur de la tête et continuer à travailler.

- Dans le travail du granulateur en mousse plastique, la tête de vis inférieure peut ajouter une ou deux couches de filtres selon les besoins. Un tamis doit en avoir plus d'un lors du travail ; si la bande n'est pas lisse, cela signifie que le tamis est obstrué, donc remplacez le tamis à temps. L'écran filtrant en acier peut être recyclé en éliminant les impuretés après avoir été brûlé au feu.

Solution de ligne de granulation de mousse EPE

La machine à pelletiser en polystyrène expansé EPE peut être combinée avec des équipements auxiliaires tels que des broyeurs, des séchoirs et des extrudeuses pour former une ligne de production complète – Ligne de granulation de mousse EPS.

Broyeur de mousse plastique

Broyez les déchets de mousse EPE en petits morceaux pour un nettoyage, une fusion et d'autres traitements ultérieurs.

Machine de découpe de granulés en plastique

coupe les bandes EPE refroidies en granulés de taille spécifiée pour former des produits finis préliminaires.

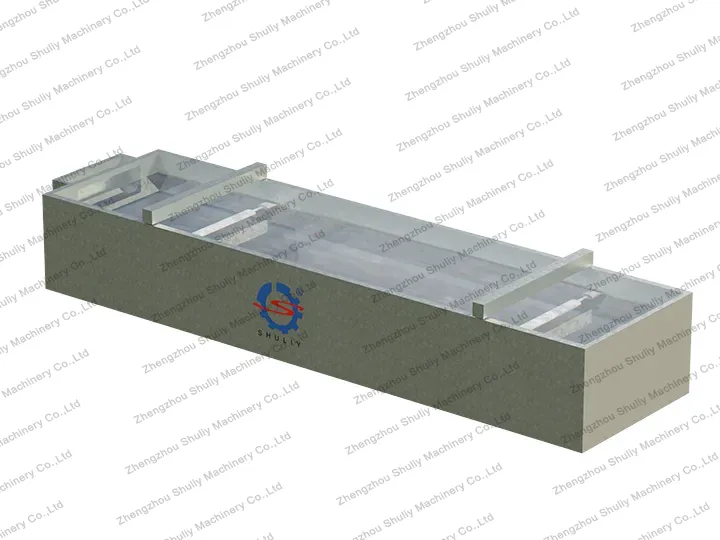

Réservoir de refroidissement

pour refroidir et solidifier rapidement la bande fondue EPE extrudée, en préparation du processus de granulation.

Bac de stockage de granules plastiques

stockage temporaire des granulés qualifiés après séchage et tamisage, ce qui est pratique pour les mesures ultérieures, l'emballage et le stockage unifié.

La configuration spécifique de la ligne de machine à pelletiser en polystyrène EPE peut être personnalisée selon vos exigences et besoins. Si vous souhaitez en savoir plus, veuillez nous laisser un message sur le site web, et nous vous contacterons dans les meilleurs délais.

Comment choisir le bon granulateur de mousse EPE ?

Les machines de granulation en polystyrène expansé Shuliy EPE sont disponibles en plusieurs modèles avec des capacités variant de 150 à 500 kg/h. Pour choisir la bonne machine pour votre usine, vous devez considérer les questions suivantes :

- Des détails sur ce que vous voulez ?

- Quelles sont vos matières premières ?

- Avez-vous une source stable de matières premières ?

- Quel est le produit final que vous souhaitez produire ?

- Quelle capacité de machine souhaitez-vous qu’elle exécute ?

Caractéristiques du granulateur en mousse plastique

- Montage libre des vis selon le type de matériau

- Alimentateur forcé à haut rendement pour garantir une stabilité d'alimentation de grande capacité et une faible consommation d'énergie

- Vis principale avec fonction d'échappement sous vide

- Extrudeuse monovis avec vis, baril et système d'échappement spécialement conçus pour garantir une bonne qualité du produit final

Avantages de l'extrudeuse en mousse plastique Shuliy

- Correspondance précise de la capacité de production : La production de la machine de granulation de polystyrène EPE varie de 150 à 250 kg/h, adaptée aux petits ateliers et aux usines de taille moyenne.

- Service de haute qualité : Des services de formation et de guidage à l'installation en ligne sont disponibles, ainsi qu'un guidage à l'installation sur site sur demande.

- Modularité : Conception personnalisée pour une utilisation autonome ou une intégration dans des systèmes complets avec les concasseurs plastiques et compacteurs, ou même dans les lignes de lavage

Le Suriname installe deux machines de recyclage de polystyrène.

Deux machines de recyclage de polystyrène ont été installées avec succès au Suriname pour le recyclage des matériaux d'emballage en mousse. Grâce à la disponibilité des modèles et des composants en stock, les machines ont été expédiées dans les 25 jours suivant la commande. Avant l'expédition, des ingénieurs ont effectué des tests et des inspections approfondis pour garantir leur bon fonctionnement.

Les machines installées comprennent la machine de recyclage SL-160 EPE et le pelletiseur SL-220 EPS, qui sont conçus pour traiter les matériaux d'emballage en polystyrène et en polyéthylène expansé. Elles sont applicables au recyclage post-industriel et post-consommation. L'équipement de configuration de base comprend un réservoir de refroidissement, une machine de découpe de granulés et un broyeur de polystyrène. Cette installation met en avant une livraison efficace et une préparation professionnelle avant expédition pour faciliter le recyclage de la mousse au Suriname.

Pourquoi recycler le coton perlé EPE à travers un extrudeur de mousse plastique ?

Avec l'application des matières premières devenant de plus en plus courante, l'augmentation résultante des déchets de coton perlé et le recyclage du coton perlé EPE sont devenus un besoin urgent pour résoudre le problème de nombreuses entreprises. Beaucoup de gens voient une opportunité commerciale dans cela, donc l'entreprise de granulation EPE a commencé. Shuliy a un granulateur EPE à vendre qui peut vous aider à démarrer votre entreprise de granulation de mousse plastique. N'hésitez pas à nous contacter.

Le coton perlé EPE a une résistance aux chocs et un renforcement de haute qualité. Il est largement utilisé dans les meubles de haute qualité, les appareils électroménagers, les instruments et compteurs, les meubles en bois, la porcelaine, les projets d'imperméabilisation des bâtiments, etc. C'est un matériau idéal.

FAQ sur la machine de pelletisation de mousse EPE

Quelles sont les causes courantes de bruit inhabituel dans la machine à pelletiser en polystyrène expansé (EPE) ?

Roulements usés / lubrification insuffisante, écart irrégulier entre la vis et le cylindre, ou fixations lâches.

Qu'est-ce qui cause une surface granuleuse rugueuse ?

Impuretés/matériaux bruts humides, faible température de tête de fil

Pourquoi la température de chauffage du granulateur ne peut-elle pas se stabiliser ?

Dommages partiels aux bobines de chauffage, provoquant une température locale inégale.