Se você está no negócio de reciclagem de EPS ou gestão de resíduos de embalagens de espuma, provavelmente está se perguntando sobre o custo do compactador de isopor. Compreender esse custo vai muito além do preço de compra da máquina. Fatores como método de compressão, compatibilidade de materiais, capacidade, nível de automação e suporte pós-venda desempenham um papel crucial. Se você está procurando um compactador de espuma de prensa a frio básico ou um sistema de compressão de EPS totalmente automatizado, este guia o ajudará a tomar uma decisão informada.

Introdução – O que Influencia o Custo do Compactador de Styrofoam?

Ao planejar investir em uma máquina de reciclagem de espuma, uma das preocupações mais comuns é o custo do compactador de isopor. Mas esse custo não se resume apenas ao preço da máquina — inclui fatores como eficiência de compressão, compatibilidade de materiais, tipo de estrutura e serviço pós-venda. Se você está procurando uma máquina de prensa fria vertical compacta ou um compactador de espuma horizontal de alta produção, entender a estrutura de preços é essencial para fazer a escolha certa.

Prensa Fria vs Derretimento a Quente: Qual Compactador de Espuma Afeta Mais o Custo?

Existem dois tipos principais de compactadores de espuma: máquinas de prensa fria e densificadores de derretimento a quente.

Os compactadores de espuma de prensagem a frio comprimem resíduos de espuma sem calor, tornando-os energeticamente eficientes e mais fáceis de manter. Os modelos de fusão a quente, por outro lado, derretem a espuma e produzem lingotes mais densos, mas requerem maior potência e investimento.

Como a Capacidade do Compactador de Espuma EPS Impacta o Investimento

Quanto maior a capacidade e maior a taxa de compressão do equipamento, maior será o preço de um compressor de espuma, que geralmente é proporcional à sua capacidade. Uma máquina que pode lidar com 200-300 kg de espuma por hora será naturalmente vendida a um preço mais alto do que um modelo de entrada que pode lidar apenas com algumas dezenas de quilogramas.

No entanto, modelos de maior capacidade tendem a ser mais capazes de operação contínua, reduzindo custos de mão de obra e espaço, e são mais adequados para estações de reciclagem de espuma de médio a grande porte ou fábricas de embalagens.

Combine Seu Compactador de Espuma à Tipo de Material

Nem todos os compactadores de espuma conseguem lidar com todos os materiais. O EPS (poliestireno expandido) é o mais comum, mas se você estiver lidando com EPE (algodão pérola) ou EPP (espuma automotiva), precisará de uma máquina com parâmetros de compressão ajustáveis. Máquinas com maior compatibilidade de materiais podem ter um preço mais elevado, mas reduzem limitações futuras.

Horizontal ou Vertical: Escolha da Estrutura para Máquinas de Prensa Fria

As máquinas de prensagem a frio vêm em dois tipos estruturais: horizontal e vertical.

- Os compactadores de espuma horizontais oferecem maior produção e suportam alimentação contínua, tornando-os adequados para instalações de grau industrial.

- Os enfardadores de espuma verticais são compactos e econômicos, ideais para pequenas oficinas ou espaços limitados.

A sua escolha aqui impacta tanto o custo da máquina quanto a eficiência operacional.

Uma Solução Completa para Reduzir o Custo do Compactador de Styrofoam

Ao avaliar o custo de um compactador de espuma, integrar um compactador de espuma com uma linha de peletização fornece uma solução completa de reciclagem: o compactador reduz o volume para facilitar o manuseio, enquanto o peletizador converte blocos comprimidos em valiosos pellets de plástico.

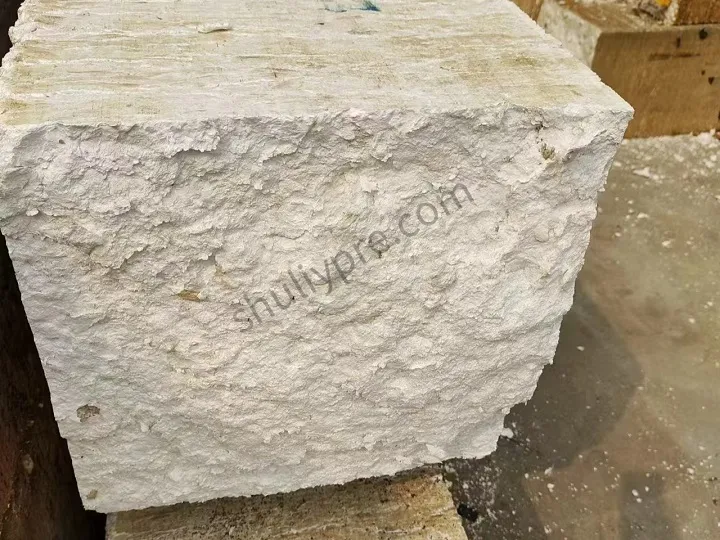

Para empresas que visam maximizar o valor da reciclagem de espuma, a integração de um compactador de espuma com uma linha de peletização oferece uma solução eficiente e ecológica. A máquina de prensagem a frio primeiro comprime resíduos de espuma EPS ou EPE soltos em blocos densos, tornando o transporte e o armazenamento mais económicos. Depois disso, o triturador de espuma plástica parte os blocos de espuma comprimidos em pequenos pedaços. Estes pequenos pedaços são, em seguida, alimentados numa máquina de peletização de EPS, onde são derretidos, filtrados e cortados em pellets plásticas reutilizáveis por uma máquina de corte de pellets plásticas.

Dicas Finais: Escolha o Melhor Compactador de Espuma para o Seu Orçamento

Ao escolher um compactador de espuma, as empresas devem ir além da comparação de preços e, em vez disso, avaliar o custo do compactador de poliestireno em sua totalidade. Isso inclui não apenas o preço de compra, mas também o consumo de energia, a mão de obra necessária, a frequência de manutenção, a disponibilidade de peças de reposição, a compatibilidade dos materiais e o valor de reciclagem subsequente.

Ao alinhar estes custos reais com a sua escala operacional, tipo de desperdício e objetivos de reciclagem a longo prazo, você pode escolher a solução mais econômica. Gerir o custo do compactador de espuma de poliestireno de forma inteligente significa otimizar seu investimento para o máximo retorno e eficiência.