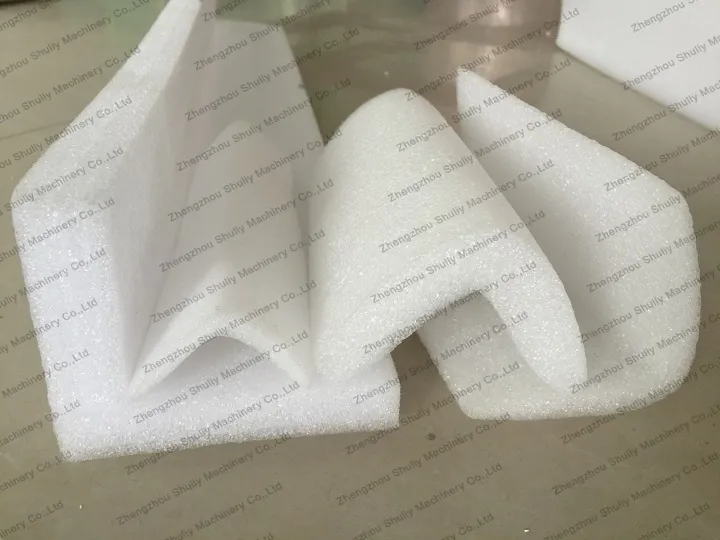

El granulador de EPE sirve para fabricar gránulos de plástico reciclado a partir de residuos de espuma de EPE mediante el proceso de trituración, fusión, extrusión, granulación y enfriamiento.

Video de funcionamiento de la máquina de pelletizado de poliestireno EPE

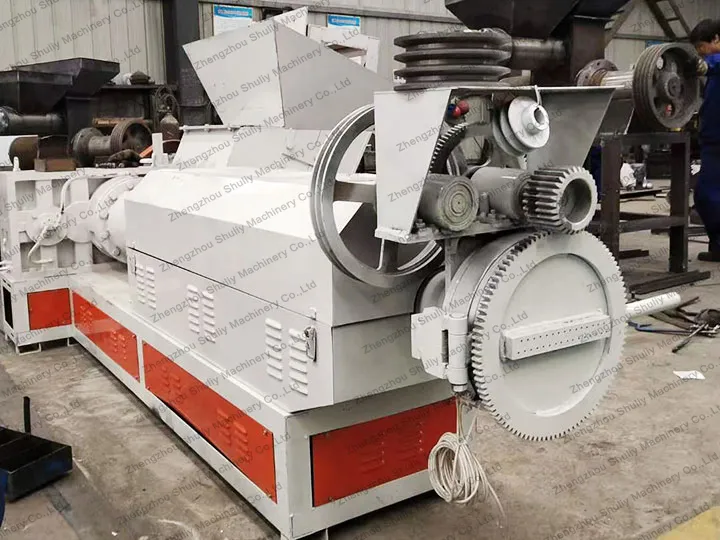

Introducción de la Máquina de Pellets de Poliestireno EPE

La máquina de pelletización de poliestireno EPE, también conocida como granuladores de espuma de plástico, puede producir pellets de plástico sin destruir la estructura molecular original. Los pellets producidos son ampliamente utilizados.

El granulador de EPE es adecuado para la extrusión y granulación de materias primas de espuma de EPE, que pueden usarse para la regeneración de espuma de EPE. El granulador de espuma plástica Shuliy adopta una estructura de escape para excluir el gas producido en el proceso de plastificación, lo que hace que los gránulos tengan una superficie densa y lisa. La operación de producción es muy sencilla y el coste de inversión es muy bajo, pero el beneficio económico es alto.

Partes principales de la máquina de reciclaje de poliestireno

Transportador de Alimentación

La entrada de alimentación adopta un diseño de entrada directa de gran diámetro, que es adecuado para la alimentación directa de materiales EPE suaves sin necesidad de pre-trituración, con alta eficiencia de alimentación y operación conveniente.

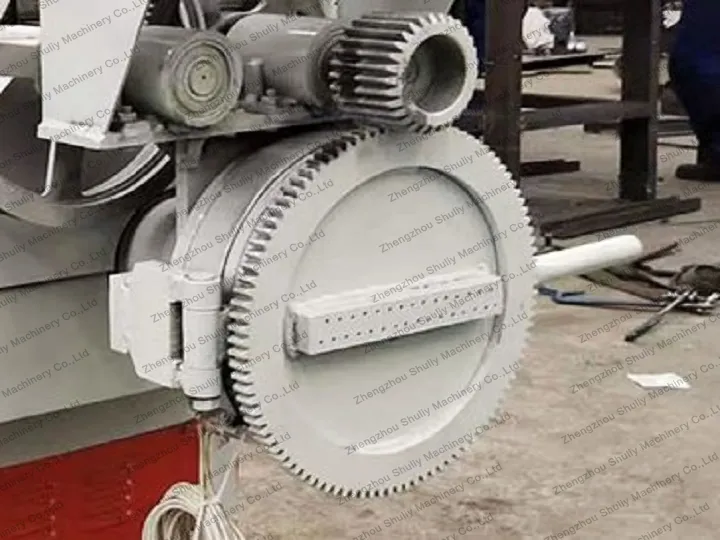

Anillo de calefacción

El anillo calefactor es para derretir la espuma y convertirla en una pasta para que pueda pasar suavemente a través de la cabeza de matriz.

Cabezal de troquel

La cabeza de matriz extruye la espuma fundida a través de sus orificios internos en tiras para el corte posterior.

Parámetros de la máquina de pelletización de poliestireno EPE

| Artículo | Detalles |

| Máquina para hacer pellets | Máquina de fabricación de pellets |

| Tanque de agua | Longitud: 4m |

| Máquina cortadora de pellets | Potencia: 1,5 kw |

¡Si deseas conocer más detalles, no dudes en contactarnos!

Proceso de línea de granulación de espuma EPE

Cuando la máquina de pelletizado de poliestireno expandido (EPE) está en funcionamiento, primero se introduce la espuma EPE desechada en la máquina a través del puerto de alimentación, y luego se tritura en piezas pequeñas por la unidad de trituración.

Luego entra en la parte central de la máquina de pelletizado, y la unidad de calefacción calienta las piezas rotas hasta el estado fundido.

Posteriormente, con la pasta en el área del tornillo en la máquina de peletizado de poliestireno expandido (EPE), el tornillo la empuja hacia el dado para ser extruida en una tira larga;

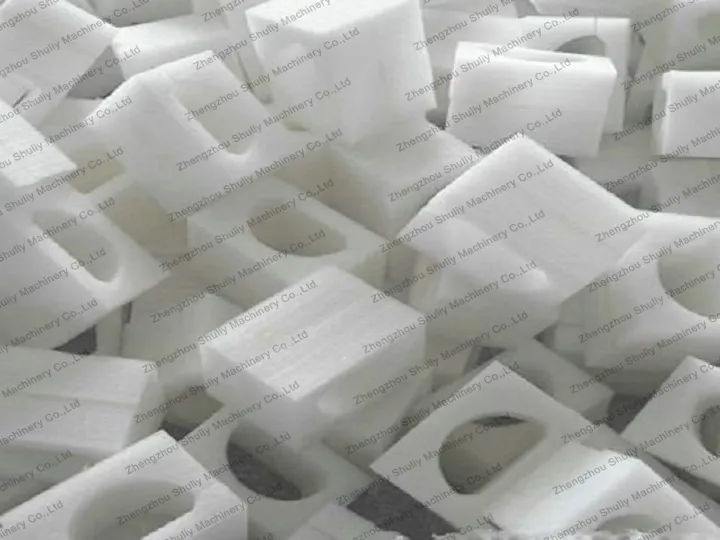

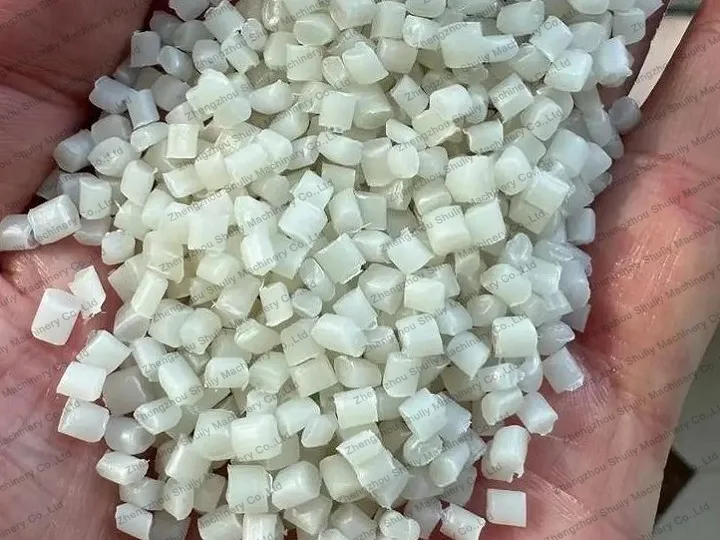

La larga tira de material en el tanque de enfriamiento se enfrió y curó rápidamente; finalmente, por la peletizadora, se cortó con precisión en pequeñas partículas para un fácil almacenamiento y transporte.

Métodos de operación de la máquina de pelletizado de poliestireno EPE

- Hay dos circuitos de calefacción en el tornillo superior e inferior de la máquina de peletización de espuma EPE, y cada circuito de calefacción tiene un interruptor, que se puede abrir y cerrar a voluntad según la temperatura necesaria para el procesamiento.

- Cuando el granulador de espuma esté funcionando, primero caliente los barriles superior e inferior durante 20 a 40 minutos, luego tome un trozo de espuma en el cabezal de la máquina y presiónelo ligeramente, si la espuma puede ablandarse y derretirse, significa que el barril se está calentando. Ha alcanzado la temperatura de trabajo y la máquina se puede encender.

- Agrega una pequeña cantidad de espuma al embudo primero. Si el material extruido se ha derretido, solo entonces se puede comenzar a trabajar con una gran cantidad de material. Si se encuentra que la temperatura es demasiado alta durante el trabajo, puedes cortar la potencia de calefacción de la cabeza y continuar trabajando.

- En el trabajo del granulador de espuma de plástico, la cabeza del tornillo inferior puede agregar una o dos capas de filtros según sea necesario. Un colador debe tener más de uno al trabajar; si la tira no es suave, significa que el colador está obstruido, por lo que se debe reemplazar el colador a tiempo. La pantalla de filtro de acero se puede reciclar al eliminar impurezas después de quemarla con fuego.

Solución de línea de granulador de espuma EPE

La máquina de pelletizado de poliestireno expandido (EPE) se puede combinar con equipos auxiliares como trituradoras, secadores y extrusoras para formar una línea de producción completa: Línea de Granulación de Espuma EPS.

Trituradora de espuma plástica

Tritura el desperdicio de espuma EPE en piezas pequeñas para su posterior limpieza, fusión y otros procesos.

Máquina de Corte de Pellets de Plástico

Corta las tiras de EPE enfriadas en pellets de un tamaño específico para formar productos terminados preliminares.

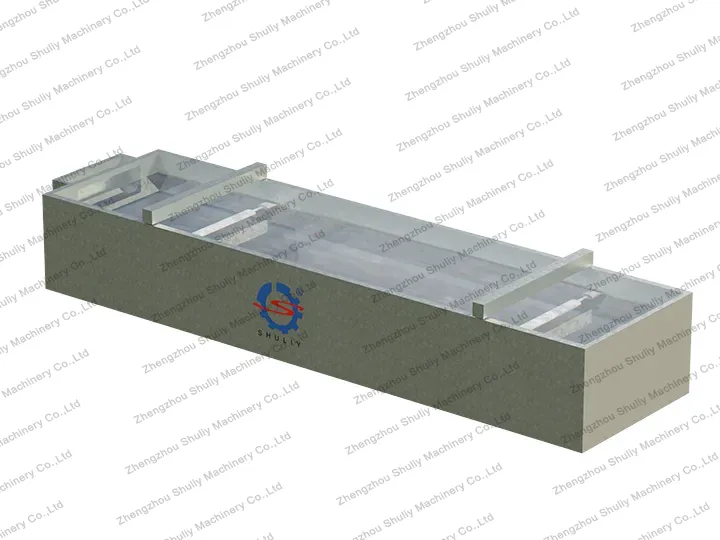

Tanque de Enfriamiento

Para enfriar y solidificar rápidamente la tira de fusión de EPE extruida, preparándose para el proceso de peletizado.

Contenedor de almacenamiento de gránulos de plástico

Almacenamiento temporal de pellets calificados después de secar y tamizar, lo que es conveniente para la medición, embalaje y almacenamiento unificado posteriores.

La configuración específica de la línea de máquinas de pelletizado de poliestireno EPE se puede personalizar de acuerdo con sus requisitos y necesidades. Si desea saber más, por favor déjenos un mensaje en el sitio web y nos pondremos en contacto con usted a tiempo.

¿Cómo elegir el granulador de espuma EPE adecuado?

Las máquinas de pelletizado de poliestireno expandido Shuliy EPE están disponibles en una variedad de modelos con salidas que van de 150 a 500 kg/h. Para seleccionar la máquina adecuada para su planta, debe considerar las siguientes preguntas:

- ¿Detalles de lo que quieres?

- ¿Cuáles son sus materias primas?

- ¿Tiene una fuente estable de materias primas?

- ¿Cuál es el producto final que desea producir?

- ¿Qué capacidad de máquina desea que rinda?

Características del granulador de espuma de plástico

- Montaje gratuito del conjunto de tornillos según el tipo de material.

- Alimentador forzado de alta eficiencia para garantizar una estabilidad de alimentación de alta capacidad y un bajo consumo de energía

- Tornillo principal con función de escape de vacío.

- Extrusora de un solo tornillo con tornillo, cilindro y sistema de escape especialmente diseñados para garantizar una buena calidad del producto final.

Ventajas del extrusor de espuma de plástico Shuliy

- Coincidencia precisa de la capacidad de producción: La producción de la máquina de peletizado de poliestireno EPE varía de 150 a 250 kg/h, adecuada para pequeños talleres hasta fábricas de tamaño mediano.

- Servicio de alta calidad: Se encuentran disponibles servicios de orientación para la instalación en línea y otros servicios de capacitación, así como orientación para la instalación en el sitio a solicitud.

- Modularidad: Diseño personalizado para uso independiente o integración en sistemas completos con trituradoras de plastico y compactadores, o incluso en tendederos

Surinam instala dos máquinas de reciclaje de poliestireno.

Dos máquinas de reciclaje de poliestireno han sido instaladas con éxito en Surinam para reciclar materiales de embalaje de espuma. Gracias a la disponibilidad de modelos y componentes en stock, las máquinas fueron enviadas dentro de los 25 días posteriores a la realización del pedido. Antes del envío, los ingenieros realizaron pruebas e inspecciones exhaustivas para garantizar su funcionamiento sin problemas.

Las máquinas instaladas incluyen la máquina de reciclaje SL-160 EPE y la peletizadora SL-220 EPS, que están diseñadas para procesar materiales de embalaje de poliestireno expandido y polietileno expandido. Son aplicables tanto para el reciclaje postindustrial como postconsumidor. El equipo de configuración central comprende un tanque de enfriamiento, una máquina de corte de pellets y una trituradora de poliestireno. Esta instalación destaca la entrega eficiente y la preparación profesional previa al envío para facilitar el reciclaje de espuma en Surinam.

¿Por qué reciclar algodón perlado EPE a través de un extrusor de espuma de plástico?

Con la aplicación de materias primas volviéndose más común, el aumento resultante de desechos de algodón perlado y el reciclaje de algodón perlado de EPE se ha convertido en una necesidad urgente para resolver el problema de muchas empresas. Muchas personas ven la oportunidad de negocio en esto, por lo que comenzó el negocio de peletizado de EPE. Shuliy tiene un peletizador de EPE a la venta que puede ayudarte a iniciar tu negocio de peletizado de espuma plástica. Bienvenido a contactarnos.

El algodón perlado EPE tiene resistencia al impacto y refuerzo de alta calidad. Es ampliamente utilizado en muebles de alta calidad, electrodomésticos, instrumentos y medidores, muebles de madera, porcelana, proyectos de impermeabilización de edificios, etc. Es un material ideal.

Preguntas frecuentes sobre la máquina de pelletizado de poliestireno EPE

¿Cuáles son las causas comunes de ruidos inusuales en la máquina de peletizado de poliestireno EPE?

Rodamientos desgastados/falta de lubricación, espacio desigual entre el tornillo y el barril, o sujetadores sueltos.

¿Qué causa una superficie granular áspera?

Impurezas/materiales crudos húmedos, baja temperatura de la cabeza de matriz

¿Por qué no puede estabilizarse la temperatura de calentamiento del granulador?

Daño parcial a las bobinas de calefacción, causando temperatura local desigual.