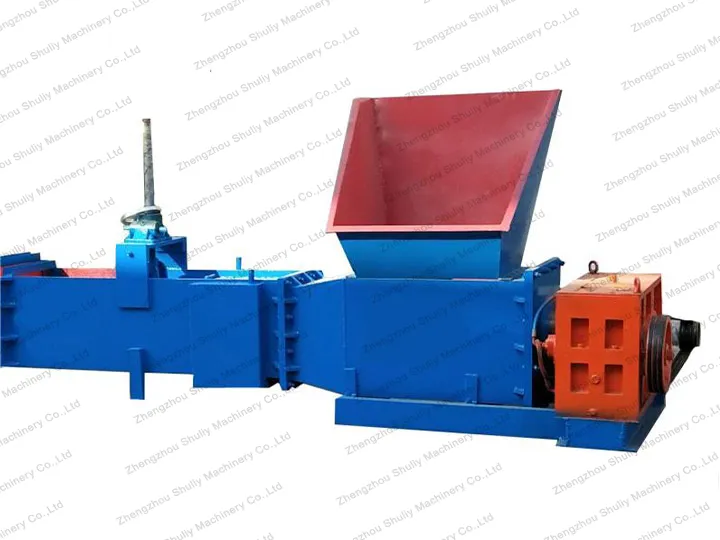

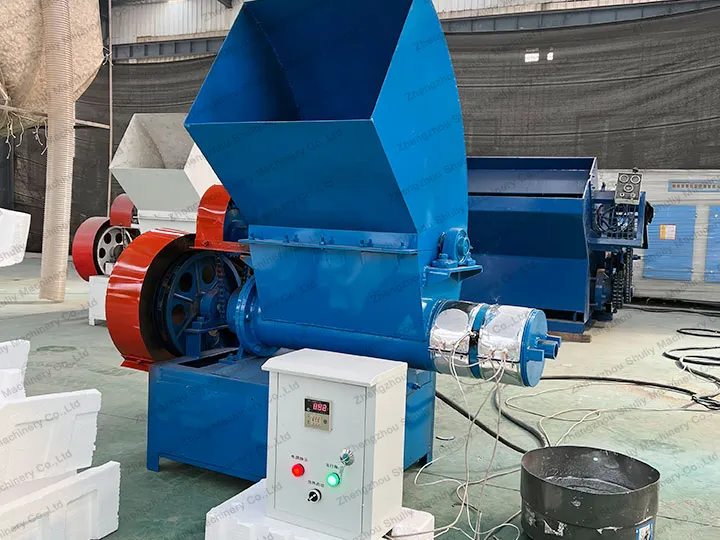

The foam melting machine is also called a styrofoam densifier. It’s used to transform the waste foam into lumps to reduce the volume and facilitate transportation. With easy operation and high output, the styrofoam melting machine is your ideal waste foam recycling equipment. The EPS densifier hot melting machine has the advantage of low input cost and high income.

Introduction of Styrofoam Densifier

La máquina de fusión densificadora de espuma de poliestireno está diseñada para resolver el problema de la reducción de la capacidad de desechos de espuma EPE de espuma seca mediante trituración, fusión en caliente y moldeo por extrusión. Es de diseño simple, estructura compacta y bajo costo de mantenimiento.

Working Principle of the Foam Densifier for Sale

An EPS densifier hot melting machine is a kind of special equipment for foam recycling, mainly used for processing thermoplastics into foam-like objects. The EPS hot melting machine’s working principle is to melt the solid plastic by heating it inside the machine to form a foam-like object. While heating, a high-speed rotating screw pushes the material forward to form a continuous production process.

Feeding:

Loose foam is manually or automatically fed into the hopper.

Pre-crushing:

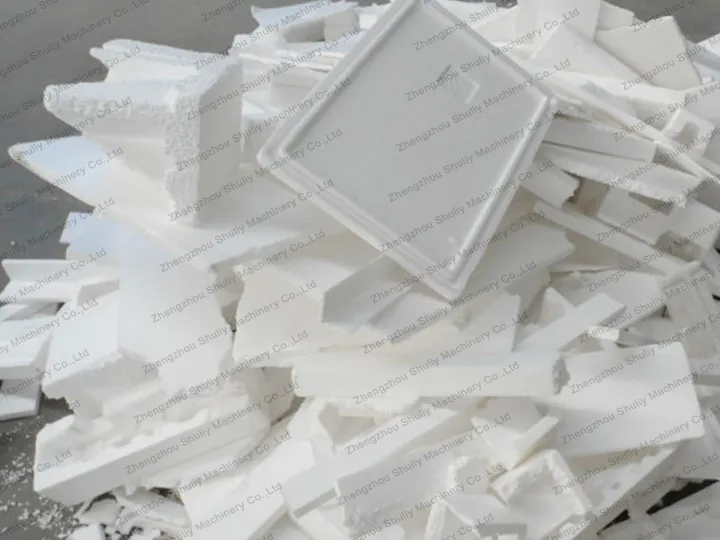

Foam is shredded to reduce size and increase compression efficiency.

Compression:

EPS is compressed or melted and extruded into dense blocks.

Cooling & Stacking:

The blocks cool quickly and are ready for stacking or baling.

Components of a Polystyrene Densifier

The foam melting machine is mainly composed of a heating system, an exhaust system, a foam system, a control system frame, and other parts. Among them, the heating system is the core part, which mainly consists of an electric heater, a temperature controller, a heat transfer pump, etc.

| Components of EPS hot melting machines | Functions |

| Feeding Hopper | Wide-mouth hopper supports manual or conveyor feeding of loose foam. |

| Compression Chamber | Reinforced steel housing with screw or hydraulic compression system. |

| Main Screw Shaft | Alloy-steel shaft for long-life, continuous torque under high loads. |

| Block Outlet | Output EPS blocks with adjustable size, shape and density. |

El sistema de escape se utiliza para eliminar los gases de escape y el vapor de agua dentro de la máquina para garantizar la estabilidad del proceso de producción.

All components of our industrial styrofoam densifier are made from wear-resistant and high-strength materials to ensure long-term stability and low maintenance.

Integration of Styrofoam Melting Machine into Automated Recycling Lines

The styrofoam densifier is not only effective as a standalone machine, but also plays a crucial role in fully automated EPS foam recycling systems. By integrating it with upstream feeding and crushing units, and downstream conveying or pelletizing machines, users can build a línea de granulación de espuma plástica.

EPS Foam Crusher

Crushes foam into small pieces before densifying.

EPS Pelletizer

Converts compressed foam into plastic granules.

Application of Styrofoam Melter

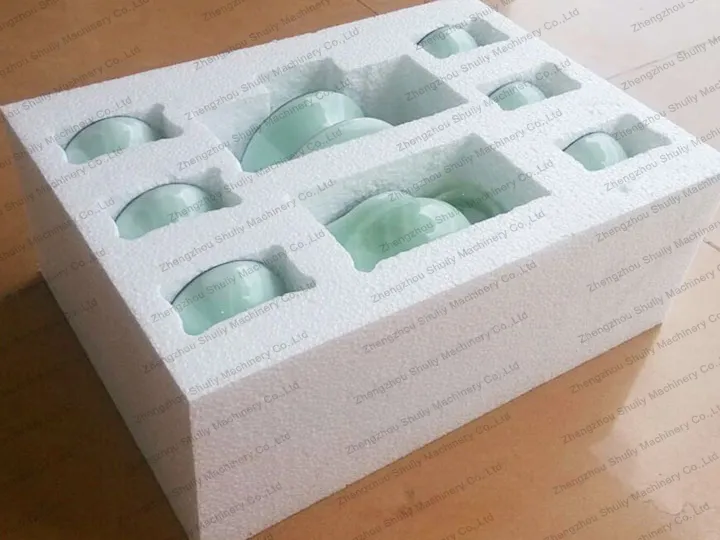

La máquina de reciclaje de fusión en caliente de EPS puede reciclar y procesar residuos de espuma producidos por la industria, la construcción, el embalaje y otras industrias.

Difference between a Styrofoam Melter and a Foam Compactor Machine

Ya sea una máquina para derretir espuma o una maquina compactadora de espuma, the ultimate goal is to compress the volume of foam. The main difference is that one melts the foam by heating, and the other processes the foam into blocks by extruding.

The material of the foam is different; if you choose the espuma de poliestireno melting machine, some pungent gas will be released at high temperatures. Some customers are resistant to this point, so you should also pay attention when choosing. To say that the compression ratio is clear that the completely melted hot melt machine is better.

Advantages of the Styrofoam Melting Machine

La máquina de reciclaje de fusión en caliente de EPS tiene las ventajas de una alta eficiencia de producción, un ciclo de producción corto y un bajo costo de producción. En los últimos años, con la creciente conciencia sobre la protección del medio ambiente a nivel mundial, los materiales de espuma ecológicos producidos por las máquinas de reciclaje de fusión en caliente de EPS también son cada vez más favorecidos por el mercado.

With the further development of society, the application field of EPS hot melting machines will be gradually expanded, and the technology level will be improved.

Si quieres reciclar espuma pero no sabes qué máquina elegir, escríbenos al sitio web. Diseñaremos una solución completa para usted.

FAQ of Polystyrene Densifier

How do I choose the right styrofoam densifier model?

Based on your material type, daily output, and space. We can help calculate the match.

Can the machine handle dirty or wet styrofoam?

We recommend clean and dry EPS for best performance. Wet foam may clog the screw.

How is the machine packaged and shipped internationally?

Machines are packed in standard export wooden cases or wrapped in stretch film for container loading.