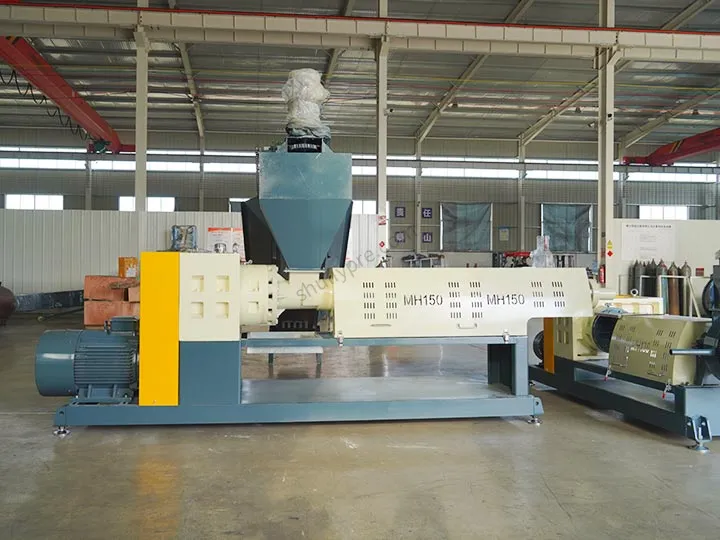

A máquina granuladora de saco tecido Shuliy, também conhecida como máquina de pelotização PP, é um tipo de equipamento especializado na conversão de sacos tecidos residuais em pellets de plástico. Os granuladores de sacos tecidos podem ser usados para reciclar sacos plásticos descartados, como sacos de pele de cobra, sacos de tonelagem, sacos de ráfia PP, sacos de cimento e assim por diante.

Introdução da Máquina de Pelotização de Plástico

A máquina granulatora de sacos tecidos é um equipamento especializado para peletizar sacos tecidos, sacos de ráfia e sacos de cimento.

Após os pedaços serem esmagados, a máquina aquece e plastifica estes materiais de sacos plásticos, e depois extruda e corta-os em pellets uniformes através do molde.

Esses grânulos podem ser usados em indústrias como embalagem, artesanato e materiais biodegradáveis. Eles ajudam a converter resíduos plásticos em recursos valiosos, promovendo a utilização sustentável de materiais naturais.

Vídeo da Máquina Granuladora de Reciclagem

Este vídeo é sobre uma máquina de grânulos plásticos em ação, mostrando como o saco tecido é processado em pellets plásticos.

Princípio de Funcionamento da Máquina Granuladora de Sacos Tejidos

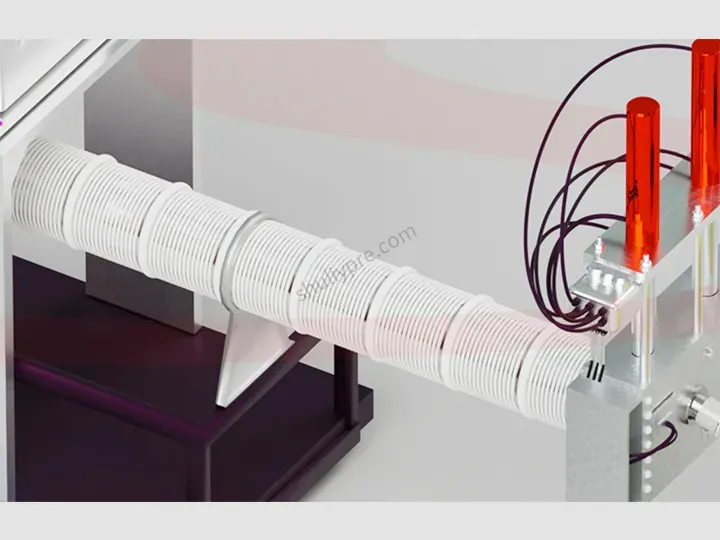

O princípio de funcionamento da máquina granuladora de saco tecido inclui principalmente as etapas de esmagamento, fusão, extrusão e granulação de saco tecido.

Primeiro, os sacos de resíduos são alimentados no triturador, que os tritura em pequenos pedaços.

Em seguida, esses fragmentos são alimentados na máquina de granulação de sacos tecidos, que converte os sacos tecidos de resíduos em um estado fundido através do processo de aquecimento e fusão.

Finalmente, o plástico fundido é extrudado através do formato da matriz ou da saída da extrusora da máquina de reciclagem de saco tecido e transformado em um material granular após o resfriamento.

Exibição de Matérias-Primas para Reciclagem de Sacos Tejidos

A máquina granulatora de sacos tecidos é usada para sacos tecidos de PP, PE, sacos de ráfia, sacos jumbo, sacos plásticos, sacos de cimento, sacos de cobra, etc.

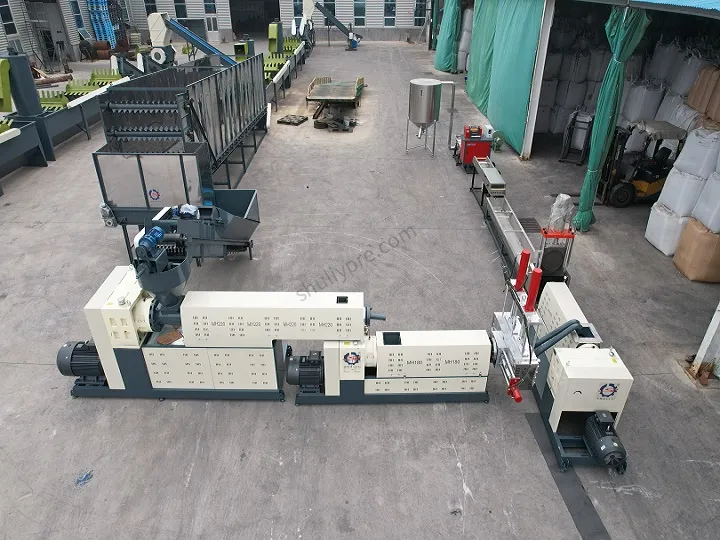

Processo de Trabalho da Máquina de Pelotização de PP

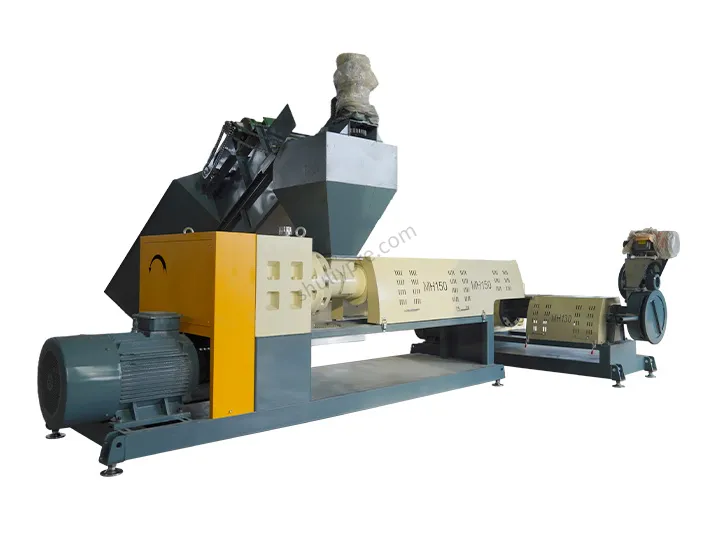

Alimentação: o parafuso no transportador de alimentação envia pedaços de plástico para granulação de forma contínua e uniforme, o que garante a estabilidade da extrusão. Além disso, a máquina substitui a operação manual e melhora o rendimento.

Aquecimento: O aquecimento eletromagnético desta máquina granuladora de reciclagem derrete os pedaços de resíduos em uma pasta.

Extrusão: Esta extrusora hidráulica automática extruda a pasta em tiras para corte subsequente.

Recomendações de configuração da máquina peletizadora de saco tecido

A seleção da máquina granuladora de saco tecido certa requer consideração do grau de limpeza do saco tecido e do efeito de pelotização desejado. A limpeza da matéria-prima pode influenciar a escolha do tipo e configuração da máquina granuladora de saco tecido. Aqui estão algumas sugestões para selecionar a máquina granuladora de saco tecido certa.

Esmagamento

Se o saco de tecido contiver mais impurezas ou poluentes, recomenda-se a escolha de uma máquina granuladora de sacos de tecido com um sistema de trituração potente. Recomenda-se um triturador de plástico de eixo duplo para que os sacos de tecido não se enrolem no eixo da máquina trituradora de plástico. Além disso, para plásticos macios como sacos de tecido, geralmente seleciona-se um alimentador automático, uma máquina peletizadora de sacos de tecido.

Lavando

A limpeza dos sacos de tecido pode ser categorizada em duas situações: sacos de tecido limpos e sacos de tecido com contaminantes. Sacos de tecido limpos geralmente estão livres de contaminantes óbvios e objetos estranhos, enquanto sacos de tecido com contaminantes podem conter impurezas, óleo, etc. Recomenda-se que fabricantes com requisitos de alta qualidade para produtos acabados configurem uma máquina de lavagem de plástico. A limpeza da matéria-prima tem um grande impacto nos pellets de plástico.

Além disso, a Shuliy pode personalizar diferentes soluções de reciclagem de acordo com diversas necessidades e atender a requisitos personalizados.

A máquina granuladora de sacos de tecido é a parte principal da linha de produção de reciclagem de plástico. Se for utilizada em conjunto com outras máquinas para formar uma linha completa de granulação para reciclagem de plástico, a taxa de utilização do equipamento pode ser maximizada.

Se você tiver alguma necessidade nesse sentido, sinta-se à vontade para nos contatar.

Vantagens da Máquina de Granulação de Reciclagem de PP

Eficiente e poupa tempo: A cabeça de extrusão hidráulica desta máquina não precisa de ser parada para ser trocada, o que poupa mais tempo em comparação com a cabeça de engrenagem mágica tradicional.

Poupança de energia e durabilidade: O dispositivo de aquecimento adota aquecimento eletromagnético em vez do método tradicional de aquecimento por folha cerâmica, o que não só poupa energia, mas também tem uma vida útil mais longa.

Casos globais de Máquina de Granulação de Reciclagem

Máquina granuladora de sacos de tecido Shuliy à venda para a Arábia Saudita, e os nossos engenheiros irão ao local para ajudar os clientes na instalação.

Perguntas Frequentes sobre a Máquina de Granulação de Sacos Tejidos

Qual é o produto final desta linha e em que áreas este produto pode ser utilizado?

O produto final são pellets de plástico. Estes grânulos encontram amplas aplicações em vários campos. Por exemplo, na indústria de embalagens, os grânulos são usados para produzir filmes plásticos e sacos de ráfia; na agricultura, para fabricar filmes agrícolas e tubos; em utilidades diárias para processar brinquedos e móveis.

Quais são as maneiras de reciclar resíduos de sacos de tecido?

Se você quiser iniciar um negócio de peletização a partir de sacos tecidos de resíduos, pode considerar as seguintes maneiras de encontrar sacos tecidos de resíduos:

Estações de reciclagem de resíduos e pontos de recolha de lixo: Trabalhe com as suas estações de reciclagem de resíduos locais, pontos de recolha de lixo ou centros de tratamento de lixo para obter sacos de tecido de resíduos.

Supermercados e retalhistas: Trabalhe com supermercados, centros comerciais ou retalhistas que geralmente têm grandes quantidades de sacos de tecido de resíduos.

Paragens de construção e áreas industriais: Paragens de construção e áreas industriais utilizam frequentemente sacos de tecido para transportar materiais de construção ou itens.

As peças desta máquina podem ser personalizadas?

Partes da máquina granuladora de sacos tecidos podem ser personalizadas, como o tamanho do pelletizador, os pellets, as tiras e o molde hidráulico automático, bem como o comprimento do parafuso na esteira de alimentação.

Se você quiser saber mais detalhes ou outras informações, sinta-se à vontade para nos contatar para que você possa obter suas soluções personalizadas.