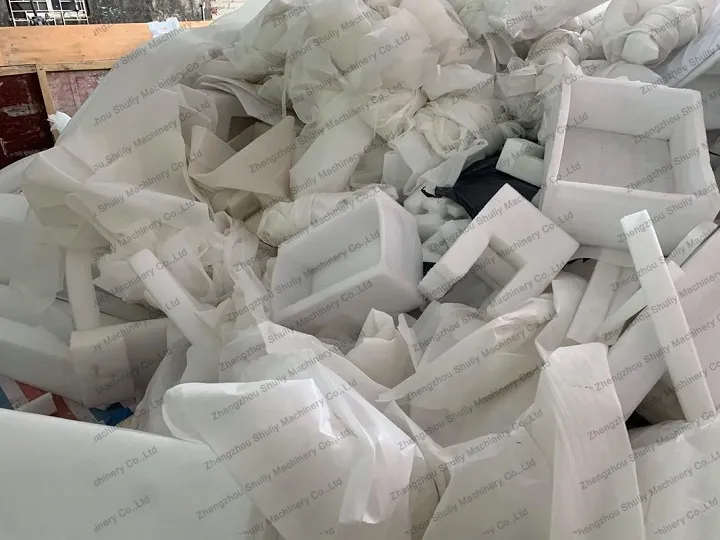

La línea de granulación de espuma plástica es una solución diseñada para el reciclaje y granulación de espuma plástica. En los últimos años, la espuma se ha utilizado ampliamente en la industria del embalaje, pero es grande y difícil de transportar. Esto ha llevado al rápido desarrollo de maquinaria y equipos de recuperación y reciclaje de espuma. Con la adopción continua de nuevas tecnologías, la tecnología de los equipos y la eficiencia de producción de las máquinas de reciclaje de poliestireno expandido generalmente han mejorado rápidamente.

Introducción a la línea de pelletizado de espuma de plástico

La línea de pelletizado de espuma de plástico recicla de manera eficiente los desechos de espuma a través de compactación, trituración, calentamiento, fusión, extrusión y pelletizado, lo que presenta una alta producción, bajo consumo de energía, operación estable, adecuada para poliestireno, etc., convirtiendo los desechos en pellets reutilizables para aumentar la utilización de recursos y la protección del medio ambiente.

La máquina de pelletizado de poliestireno expandido para el reciclaje de espuma plástica es un sistema industrial integrado diseñado para reciclar desechos de espuma plástica en pellets plásticos reutilizables. Este proceso transforma desechos de espuma voluminosos y de bajo valor en materias primas de alta calidad para la producción de nuevos plásticos. La línea combina típicamente tecnologías de trituración mecánica, fusión térmica y pelletizado para lograr un reciclaje eficiente de materiales, abordando tanto la contaminación ambiental como los desafíos de escasez de recursos.

Video de Trabajo de Reciclaje y Pelletización de Espuma EPS

Flujo del proceso de la línea de pelletizado de espuma de plástico

Trituración – aglomeración – estirado – enfriamiento – granulación

La línea de peletización de espuma de plástico está 100% disponible para espuma reciclada. La espuma EPS EPE se comprime y luego se peletiza, lo que la convierte en el método de procesamiento reciclado más utilizado. La espuma es comprimida o derretida térmicamente por un compresor de espuma profesional, lo que resulta en un bloque comprimido. Los bloques de espuma triturada y comprimida se pueden utilizar para la peletización y producir pellets de EPS EPE de alta calidad. Se puede aplicar a la producción de nuevos productos de espuma. Ahora, con la creciente popularidad de la reducción de emisiones de carbono, el reciclaje se ha convertido en el método principal para regenerar EPS.

Existen algunas diferencias entre la peletización de EPE y EPS en la línea de granulación de espuma de EPE EPS. La espuma de EPE es blanda, y el granulador para procesar este tipo de espuma generalmente contiene un dispositivo de alimentación automático. Además, la espuma de EPE no necesita un triturador para el preprocesamiento, por lo que se puede introducir directamente en el granulador.

La espuma de EPS suele ser de gran tamaño, lo que significa que la espuma de EPS necesita ser triturada por una trituradora y compactada. Como resultado, este tipo de espuma puede entrar en el granulador para su procesamiento.

Máquinas principales de la línea de granuladores de espuma de plástico

Trituradora de espuma de plástico

La trituradora de espuma plástica se utiliza para triturar grandes trozos de espuma reciclada en trozos pequeños que se pueden derretir y granular fácilmente.

Máquina compactadora de espuma

Debido a la baja densidad y gran volumen de la espuma, necesita ser comprimida por la máquina compactadora de espuma después de ser triturada para mejorar la eficiencia del transporte del material.

Extrusora de espuma plástica

La extrusora de espuma plástica se utiliza para fundir y extruir pequeños trozos de espuma plástica triturada en tiras largas.

Tanque de enfriamiento

El tanque de enfriamiento se utiliza para enfriar las tiras de plástico de alta temperatura para que se endurezcan y se puedan cortar fácilmente.

Cortador de gránulos de plástico

El cortador de gránulos de plástico se utiliza para cortar tiras largas de plástico enfriado y endurecido en gránulos de plástico de tamaño uniforme.

La configuración concreta de la línea de granulación de espuma EPS se puede ajustar según los requisitos personalizados de los clientes. No dude en contactarnos, y adaptaremos soluciones de reciclaje perfectas para usted.

Materias Primas y Productos Terminados de la Línea de Pellets de Espuma Plástica

La línea de granulación de espuma plástica puede producir gránulos de plástico a partir de residuos de espuma reciclados.

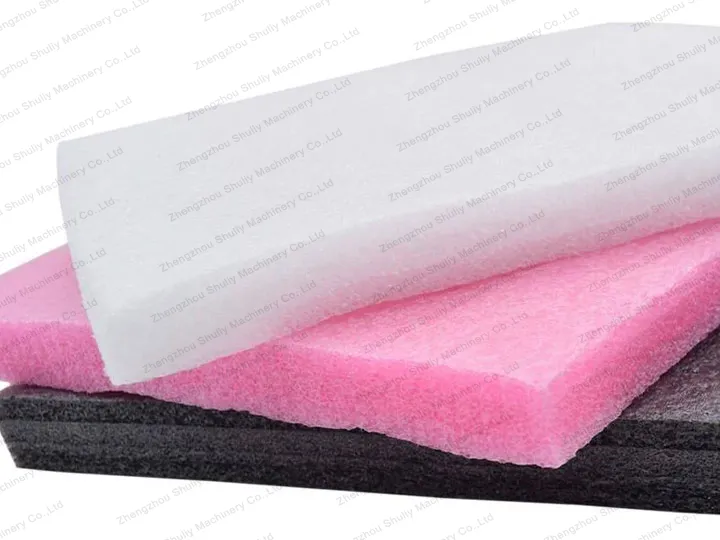

Polietileno expandido

El Polietileno Expandido es una espuma estructural hecha de polímeros de polietileno. Se fabrica calentando y comprimiendo el polímero de polietileno para formar burbujas de aire que lo hacen liviano, flexible y con propiedades de aislamiento acústico y térmico. Se utiliza principalmente en embalaje, construcción y aplicaciones domésticas.

Poliestireno expandido

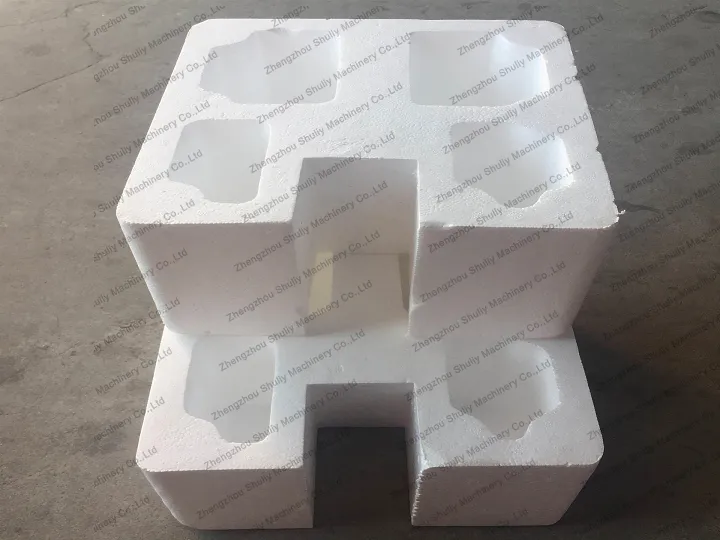

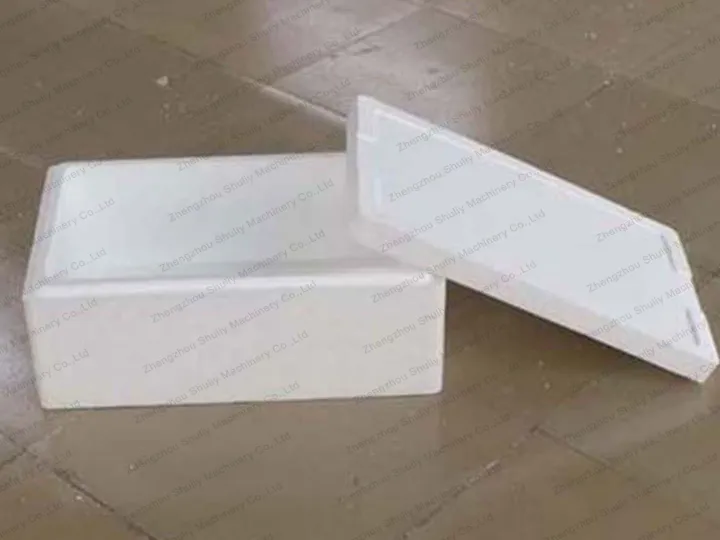

El EPS, o poliestireno expandido, es un material liviano, rígido y termopar hecho de pequeñas bolitas de poliestireno. El EPS se utiliza comúnmente para aplicaciones de aislamiento, embalaje y acolchado protector debido a su bajo costo, versatilidad y buenas propiedades de aislamiento.

Para fabricar EPS, se mezclan pequeñas partículas de poliestireno con un inflador, como el propano, y luego se calientan y se moldean en bloques grandes. El inflador forma pequeñas burbujas dentro de los pellets, lo que hace que se expandan y formen un organismo. Dependiendo de la aplicación deseada, el proceso de expansión se puede controlar para producir EPS con diferentes densidades y propiedades físicas.

Si no está muy seguro de si los materiales existentes que tiene se pueden peletizar en la línea de granulación de espuma EPE EPS, no dude en dejar un mensaje en nuestro sitio web. Nos pondremos en contacto con usted a tiempo.

Aplicaciones de los gránulos de plástico reciclado

El material EPE EPS se usa ampliamente en los siguientes campos debido a sus propiedades livianas, elásticas, a prueba de humedad, a prueba de golpes y resistentes a la corrosión.

- Embalaje: A menudo se utiliza para el embalaje de productos electrónicos, alimentos, cosméticos, industriales y otros artículos para protegerlos de daños durante el transporte.

- Construcción: El polietileno espumado se utiliza a menudo en la construcción, como por ejemplo para tabiques, aislamiento acústico, aislamiento térmico, protección, etc.

- Muebles: Se utiliza comúnmente en la fabricación de muebles como sofás, asientos, colchones, almohadas, etc., para proporcionar comodidad y buen soporte.

- Equipos deportivos: Se utiliza a menudo para la fabricación en seco de equipos deportivos como trampolines, equipo de protección, etc.

- Electrónica: Se utiliza a menudo para la fabricación en seco de productos electrónicos, como fundas para teléfonos móviles, bolsas para computadoras, equipos fotográficos, etc.

Características de la línea de pelletizado de espuma de plástico

La máquina de reciclaje de poliestireno expandido se utiliza para reciclar y granular espuma EPE y EPS. Es especialmente adecuada para la clasificación de materiales y convertir desechos en tesoros.

- Alta capacidad de producción: La línea de pelletización de espuma plástica, con una tasa de producción de 250 kg/h, asegura un manejo eficiente del procesamiento de desechos de espuma a gran escala.

- Diseño tecnológico y protección estética: La línea de pelletizado de espuma de plástico adopta la última tecnología, con un aspecto generoso y hermoso, y es fácil de usar.

- Producción continua automatizada: La línea de granuladores de espuma plástica puede realizar una producción automática y continua.

Caso de exportación de la línea de granulación de espuma EPE EPS

En 2025, una empresa mexicana de reciclaje de plástico con visión de futuro optó por la máquina de pelletización de poliestireno EPE SL-180 de Shuliy. Enfrentando el desafío de manejar grandes láminas de EPE y desechos de embalaje de espuma, el cliente necesitaba una solución eficiente para convertir este material voluminoso en pellets valiosos. La línea SL-180, con su capacidad de salida de 250 kg/h, construcción robusta y diseño fácil de usar, resultó ideal.

La Línea de Peletización EPE SL-180 exportada con una tasa de producción de 250 kg/h ayuda al cliente mexicano a aumentar la eficiencia del reciclaje, reducir los residuos en vertederos y crear un nuevo flujo de ingresos vendiendo pellets de alta calidad.

Preguntas frecuentes sobre la máquina de reciclaje de plástico

¿Cuál es la capacidad de producción típica de la línea de granulación de espuma EPE, EPS?

La línea de peletizado de espuma de plástico cuenta con una tasa de producción de 200-250 kg/h, dependiendo de su materia prima.

Si desea más información detallada, no dude en ponerse en contacto con nosotros.

¿Se puede peletizar espuma húmeda directamente en la línea de peletización de espuma de plástico?

No. La humedad causa burbujas en el fundido y gránulos agrietados; debe secarse mediante aire caliente o deshidratación centrífuga.

¿Por qué se decoloran los gránulos?

En una línea de peletizado de espuma de plástico, las posibles causas pueden ser una temperatura de extrusión demasiado alta (degradación del plástico), contaminación de la materia prima o filtros obstruidos. Verifique el control de temperatura y limpie las impurezas.