The plastic crushing machine blade is made of alloy steel, which is high-temperature resistant and durable. The blade is the key part of a plastic crusher, mainly used to crush materials. Shuliy Group’s plastic crusher is suitable for plastic drums, plastic pipes, plastic films, plastic belts, woven bags, plastic bottles, etc.

Plastic crushing machine blade parts

A plastic shredder blade is a kind of mechanical blade used for double-shaft plastic shredders. The plastic crushing machine blade consists of a fixed knife, claw knife, and spiral roller knife. The claw knife and spiral hob knife have high-speed rotating blades to crush plastic products. It has high production efficiency, cut out the particles evenly, and so on. The plastic crusher blade combination structure manufacturing process is more complex than the flat knife.

Selection of plastic crushing machine blades

According to the type of material crushed choose the right blade, which helps to improve the quality of crushing. It can also improve the service life of the plastic crushing machine. In addition, the distance between the blades in the plastic shredder can be changed to adapt to the crushing of different sizes and shapes of materials.

Paddle crusher blade: It is suitable for softer materials, such as plastic film, ton bags, woven bags, etc.

Claw Crusher Blade: It is suitable for hard raw materials such as plastic barrels, bottles, pipes, rubber tires, etc.

Use and maintenance of plastic crushing machine blades

Plastic crushing machine knives as wearing parts, so it is necessary to replace them. Plastic shredder knives are a little expensive, so in order to use them more economically and practically, Shuliy Machinery recommends that users purchase a plastic crushing machine blade when buying another set of spare knives. When the tool needs to be replaced directly when the replacement is down. Then the worn shredder knife with a knife grinder to sharpen. Such recycling is economical and practical and does not delay the normal operation of the shredder equipment, it is a twofer.

When to resharpen plastic crushing machine blades?

Shuli machinery to remind you of the following circumstances need to promptly polish the blade.

- When the quality of the shredder blade no longer meets the requirements

- When the energy consumption of the machine starts to increase significantly

- The cutting material edge has a large burst when

- When the wear of the alloy edge reaches 0.2mm

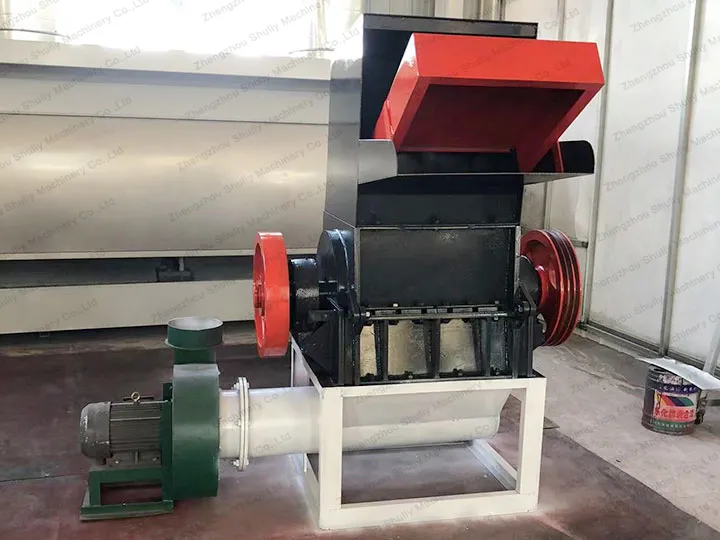

Shuliy Group’s different models of plastic crusher show