Waste plastic crusher is designed to grind PP, PE, LDPE, PVC, PET, HDPE, ABS, and other soft or hard plastic scraps. Such as plastic films, plastic bottles, PVC pipes, PE pipes, etc.

By changing the screen with different apertures, we can get different particle-size flakes.

Introduction of Waste Plastic Crusher

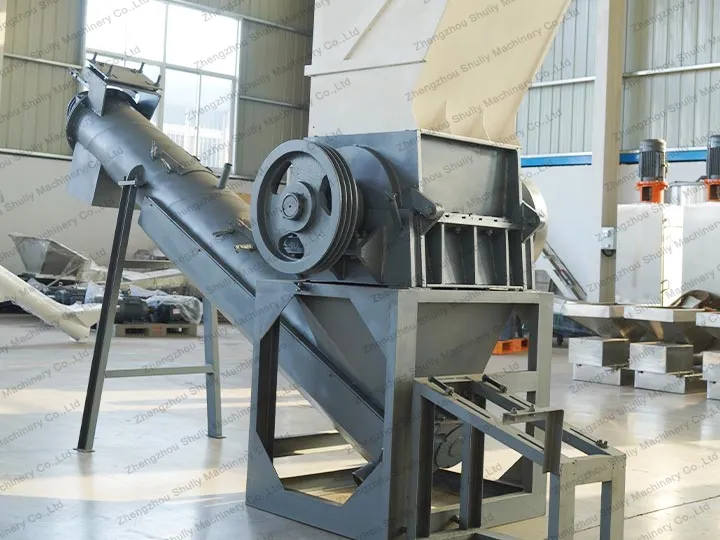

A plastic waste shredder machine is a recycling equipment that specializes in crushing waste materials into pieces, which is widely used in the industries of plastic recycling, regeneration and granulation, waste products processing, and environmental protection resource utilization.

It crushes scraps by cutting and shredding them into small flakes through the high-speed rotating blades. This step is convenient for subsequent cleaning, melting, extruding, and pelletizing.

The crushing machine is an important piece of equipment in the plastic pelletizing line, which greatly improves production efficiency.

Plastic Crushing Machine Principle

The working principle of the plastic recycling shredder is that the movable knife rotates at high speed while cooperating with the fixed knife to cut large pieces of plastic. After that, the material is filtered through the screen and output.

Structure of Shredder Machine

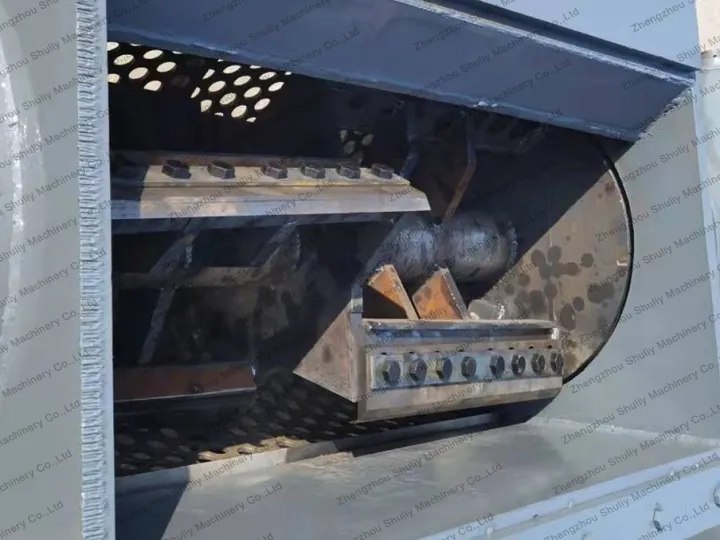

A plastic shredder machine is mainly composed of a feeding hopper, shredding chamber, knife frame, screen plate, lower hopper, motor, and so on.

The crushing chamber of the crushing machine serves as the place where the material is broken down. There are moving blades, fixed blades, screens, and other accessories in the crushing chamber.

Plastic Grinding Machine Application

Industrial grinder machine can crush HDPE, LDPE, LLDPE, PET, PVC, ABS, etc., like buckets, baskets, trays, straws, irrigation pipes, auto bumpers, film, shopping bags, woven bags, electronic meters, bubble wrap, cosmetic tubes, bag cut-offs, agricultural films and other plastic scraps.

The crushed granules can be directly used as raw materials for granulation.

Industrial Plastic Shredder Parameters

| Model | SL-60 | SL-80 |

| Capacity | 500kg/h | 1t/h |

| power | 15+7.5w | 30+11kw |

Waste Plastic Crusher Working Process

Step 1:Feeding

The waste plastics (such as bottles, films, woven bags, pipes, etc.) are fed into the crushing chamber of the waste plastic crusher through the inlet or conveyor belt. Some models are equipped with a pressure device to prevent the material from rebounding.

Step 2:Crushing

The crushing chamber of the waste plastic crusher is equipped with a set of rotating knives (movable knives) and fixed knives. When the plastic enters the area of the blades, a strong shearing and tearing effect is formed between the movable knife and the fixed knife, thus breaking the plastic material into small pieces.

- The movable knife rotates with the knife shaft at high speed.

- The fixed knife is fixed in the knife frame or side wall.

Step 3:Sizing

The crushed material falls to the screen structure (sieve plate) at the bottom of the machine, and only the crushed material with a particle size smaller than the sieve hole can pass through.

- Only material with a particle size smaller than the holes in the sieve passes through. Material with a particle size too large for the sieve continues to be crushed.

- The screen can be replaced to control the size of the material to be discharged.

Notes on Waste Plastic Crusher Shredder Machine

- Regularly check the bearings and replace the high-speed grease to ensure the normal operation of the industrial shredder.

- After work, the shredder machine must be cleaned of all parts of residual materials.

- When the crusher is in use, if the spindle speed is found to be gradually decreasing, the motor must be adjusted downward so that the machine can reach the specified speed, and any abnormalities found should be stopped for inspection.

- When the plastic crushing machine is turned on, the inflow of metal materials such as nails, iron, and so on into the machine is strictly prohibited.

- When using the first no-load test for 1-2 minutes, observe no abnormal phenomenon before feeding.

- Feeding should gradually increase the flow of material, and keep observing the motor power consumption and operation.

Advantages of Plastic Recycling Shredder

- Simple structure, small volume, lightweight, low power consumption per unit product

- The front and rear walls of the crushing chamber adopt double-layer sound insulation, and low-noise

- Smooth movement, low vibration, easy operation

- Strong cutting force, high productivity, large crushing ratio, uniform fragment size

- Separate feeding hopper, crushing chamber, and screening hopper, easy to load and unload

- The special design of the crushing chamber, no hopper, large inlet, and easy to load

- The crushed corners can be directly sent to the extruder

FAQs of Plastic Shredder Machine for Recycling

How does a plastic shredder machine for the recycling process of plastic bottles, films, and woven bags?

Plastic bottles, films, and woven bags can be fed directly into the shredder machine, where the machine’s blades will cut them into smaller particles or fragments by shearing. For larger or harder materials, pre-processing is recommended (e.g. foam compressor).

What size materials can the Waste plastic crusher handle?

Different models of Waste plastic crushers can handle different sizes of materials. Generally speaking, the inlet size, blade design, and power of the machine will affect the processing capacity. You need to choose the right model according to the actual demand.

How often do I need to change the blades of my plastic shredder?

The frequency of blade replacement depends on the usage, the hardness of the material being processed and the blade material. In general, if the blades are worn or not sharp, they should be replaced promptly.

Inquiry

For information about the crusher machine price, capacity, and model, please leave your message on the website. We will send you a detailed quotation and catalog.