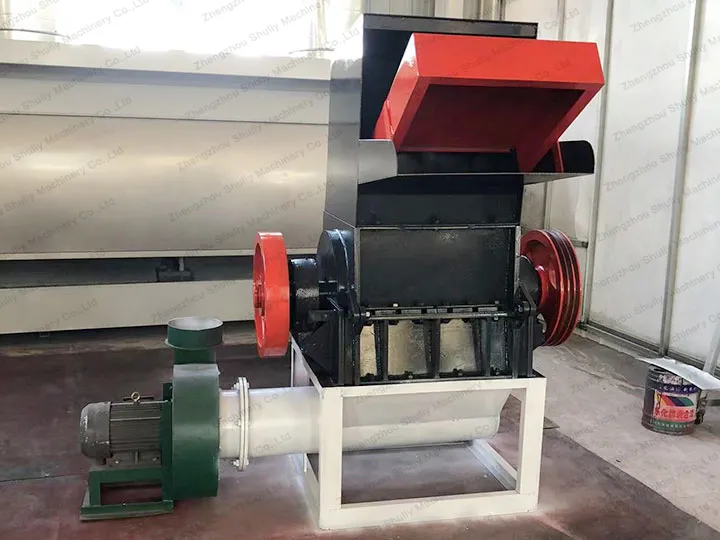

The correct method of disassembling and assembling automatic plastic crusher blades and understanding how to repair and polish bottle crusher blades can save you a considerable amount of money in equipment consumption. Here are some tips on plastic scrap shredder machine grinding and disassembly respectively. I hope this will be of some help to you.

How to sharpen automatic plastic crusher blades?

In automatic plastic crusher equipment, the blade is a very important accessory. No matter what the material of the blade, after a long time of use will be changed. So when the blade is worn out how to deal with it? Throw it away? That is not possible, because this will lead to cause many unnecessary losses of interest. The following three bottle crusher blade grinding methods.

- Surface grinder grinding: the grinding effect of the surface grinder is very good so that the grinding out of the metal blade can effectively protect the blade. And the protection effect is very good, and grinding quality is very guaranteed.

- Grinding wheel to polish: grinding wheel is more common in our daily life, and the frequency of its grinding wheel is also very high. For people who did not know much about this before, the use of grinding wheels to grind machines and equipment blades is a very good choice The operation of the familiarity can reduce our mistakes in the grinding process.

- Automatic sharpening machine grinding: the automatic grinding machine is characterized by time and effort saving, and the operation is relatively simple.

How to install plastic scrap shredder machine blades?

The automatic plastic crusher blade is the center of the whole equipment, in the production process, sometimes the installation errors will lead to the phenomenon of card machines with the material. This phenomenon is very troublesome, once encountered the card machine should be stopped to check.

Plastic scrap shredder blade installation is not in place will lead to misalignment of the blade in the machine running process will create a lot of unwanted noise also seriously affect the service life of the blade. The good or bad of the bottle blade directly affects the quantity and quality of the crusher. Here is how to disassemble the plastic scrap shredder machine correctly.

- The first thing to note is that the alloy head has a sharp and lively edge. Therefore, it is necessary to pay attention to avoid damage to the alloy head in the process of moving and dismantling the plastic scrap shredder machine blades.

- Check the radial runout of the bottle crusher spindle and the swing on time, and make sure that the automatic plastic crusher blades are blocking each other.

- Before disassembling and assembling the blades of the plastic scrap shredder remove the debris on the main shaft and flange. The surface of the flange should be flat, clean, and perpendicular to the intersection of the shaft.

- The flange nut should be loosened and tightened moderately, too loose will cause the saw blade to slip when rotating and cutting, and too tight saw blade will have internal injuries or deformation, which will affect the cutting effect of the automatic plastic crusher.

- Operators need to bring good protective equipment, such as protective glasses, dust masks, helmets, protective gloves, and so on.