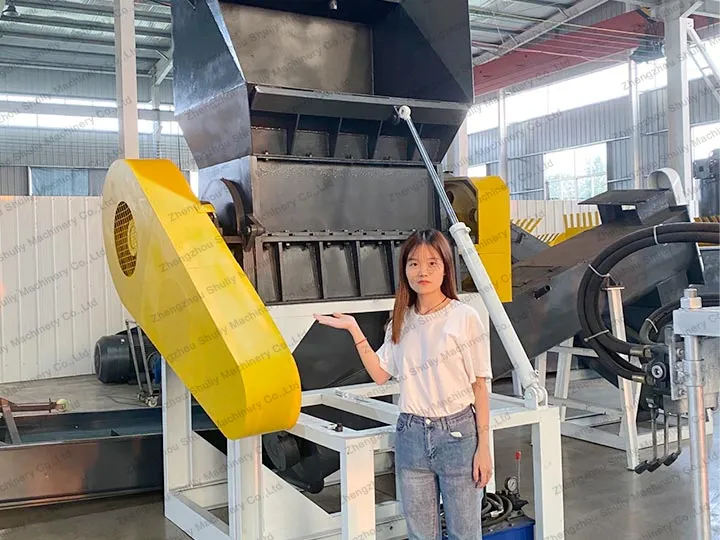

The plastic shredding machine is mainly used to crush plastic waste into small pieces for further recycling and granulation. It plays a key role in the recycling industry. Soft and hard plastics are common types of recycled plastics. Generally, they are best processed with different types of plastic pulverizer machines.

Soft plastic shredding machine

Soft plastic shredding machines are designed to process soft and lightweight plastic materials such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). These materials are commonly used in plastic films, bags, and packaging. Soft plastic grinding machines utilize blades made of high-strength steel and are designed for the efficient cutting of soft plastics.

Hard plastic pulverizer machine

On the other hand, hard plastic shredding machines are specialized in processing hard and tough plastic materials such as polystyrene (PS), polyamide (PA), and polycarbonate (PC). These materials are commonly used in plastic pipes, sheets, and various hard plastic products. Rigid plastic grinding machines are equipped with more durable alloy steel blades and a sturdy design to withstand the resistance of hard plastics. Due to the rigidity of the plastic material, the shredding process may require more power and time.

Crushing efficiency of plastic shredding machine

Soft plastic pulverizer machines are more efficient than hard plastic pulverizers. Soft plastics are more malleable and can be cut into smaller particles more quickly. In contrast, hard plastics are tougher and require more force to break, making them less efficient to crush.

Additionally, hard plastic shredding machines typically consume more power than soft plastic grinding machines due to the different properties of the plastic materials being processed. Soft plastic pulverizer machines require less power to process soft materials.

What kind of plastic shredding machine is right for me?

The key to selecting the right plastic pulverizer machine is to determine the type of plastic you want to process, consider capacity requirements and pulverization size, and focus on safety features and energy costs. You should also consider the size of your plant and how the plastic shredding machine should be positioned within the line to ensure efficient, consistent, and economical recycling of plastics.