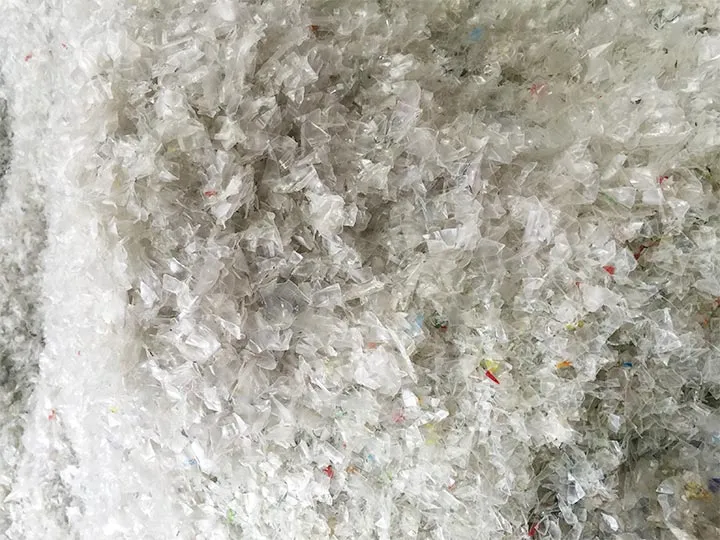

The hot washing tank cleans PET bottle flakes by rubbing them against each other through the high-speed agitation of the spiral at the bottom. The hot-washed PET bottle flakes can be made into polyester filament.

Introduction to Hot Washing Tank

PET bottle flakes hot washing machine is a necessary equipment for producing food-grade or fiber-grade bottle flakes. Adding this hot water washing machine to PET, HDPE, PP, PE, and other plastic washing lines can effectively remove adhesives, waste residues, beverage food residues, odors, and other contaminants.

Parameters of Hot Washer Tank

- Wash PET chips with hot water and a cleaning agent

- Power: 4 kW

- Size: 1.3*2m

PET Bottle Washing Tank Working Principle

The plastic recycling hot washer performs deep cleaning by placing the plastic sheet in high-temperature water of about 80-90°C and adding caustic soda or cleaning agent.

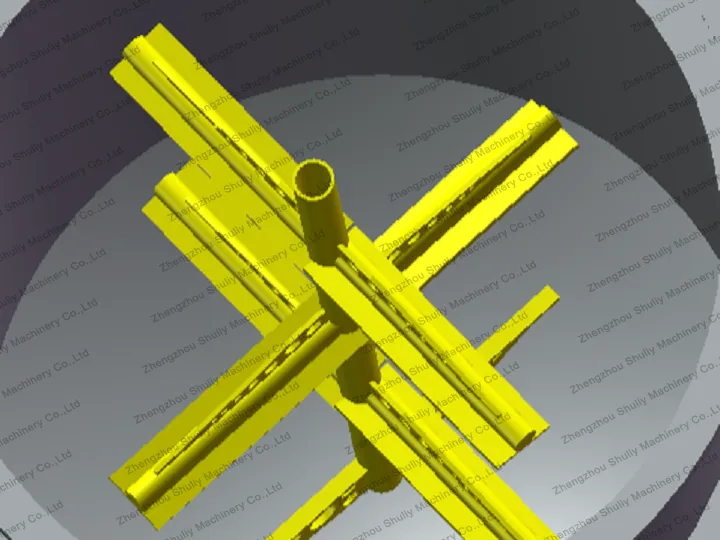

The PET bottle washing tank is equipped with a motor-driven agitator, which continuously stirs the material and brings it into full contact with the hot water, effectively removing contaminants such as oil, label residue, glue, food residue, and other contaminants.

| Steps | Details |

| Chemical Heating: | The water is warmed up by an electric heating system while caustic soda or cleaning agent is added. |

| Stirring and washing: | Motor-driven stirring device, continuously stirring the material to ensure uniform and thorough cleaning. |

| Contaminant Removal: | An electric heating system warms up the water while caustic soda or a cleaning agent is added. |

Features of PET Flakes Hot Washing Machine

- Bottom discharge design, water, and cleaning agent can be retained in the high-temperature steamer without being taken away, thus reducing the loss of water and cleaning agent

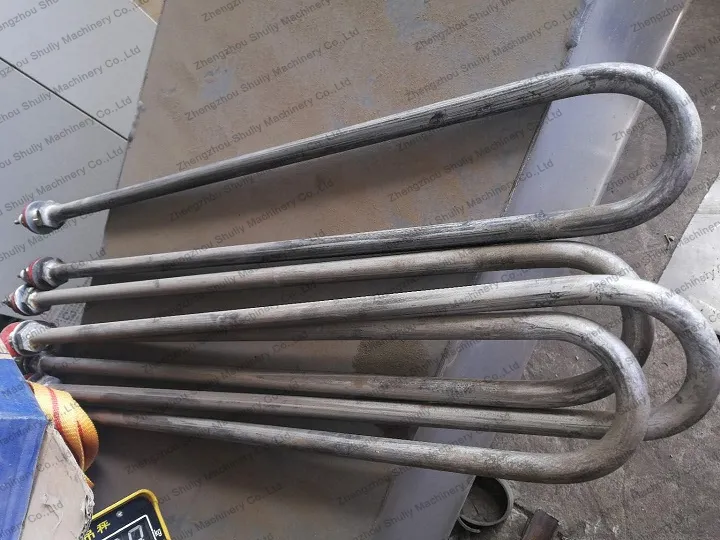

- Thickened steel plate material manufacturing, wear-resistant, corrosion-resistant, and longer hot-washed PET flakes machine life

- Electromagnetic heating, fast heating speed, can improve the productivity of a hot washing pot

- Independent control of temperature control, electric box, to protect the heating temperature stability and continuous and safe operation of the machine

- Brand motor, strong power, and high-quality

- The built-in stirring device can let the water cleaning agent and bottle piece fully contact, making stubborn dirt clear and easier to fall off

Application of PET Bottle Flakes Hot Washing Machine

PET flakes hot washing machine is mainly used for high-temperature washing of PET, ABS, PC, HDPE, and other hard plastic flakes.

Precautions for the Use of Hot Water Washing Machine

The temperature and duration of the PET bottle washing tank will also affect the price of the final PET flakes. The water temperature in the PET bottle hot washing machine is best controlled at 85-95 degrees, and the cleaning time is best at 30-45 minutes.

When using, you need to fill the watermark water level, the working process needs to constantly replenish the water lost due to heating evaporation or other ways to ensure that the actual water level is at the mark water level.

Why do PET Flakes Need Hot Washing?

In textile applications, for example, plastic cold-washed flakes can be processed into polyester staple fiber after recycling. After recycling of hot-washed plastic, it can be made into polyester staple fiber or polyester filament. Polyester long fiber can make all kinds of clothing, home textiles, decorative materials, and a variety of industrial products.

In the market, hot-washed bottle flakes are recycled by a high-temperature washing tank at a higher price.

Hot Washer Tank Improving PET Flake Quality in South Sudan

The hot washing tank produced by Shuliy has been successfully exported to South Sudan, and the Hot washer tank has been installed and put into use in the customer’s factory. The high-temperature washing tank has been installed and put into use in the customer’s factory. The machine runs stably and has high cleaning efficiency, which significantly improves the cleanliness and added value of the local PET bottle flakes recycling, and has been highly evaluated by the customer.

“The hot washing tank runs smoothly and delivers consistent high-temperature cleaning. Our recycled PET flakes are now much cleaner and meet export standards. It’s energy-efficient and easy to maintain. This machine has really improved our production line.”

— James Lado, South Sudan

Wholesale PET Flakes Hot Washing Machine

The main function of a hot washing tank is to effectively remove impurities and chemical residues from the PET bottle flakes, thus ensuring the subsequent product quality. Wholesale PET flakes hot washing machine manufacturers recommend that you have a plastic recycling hot washer in your PET bottle recycling line.

Shuliy Machinery is a professional hot-washed PET flakes machine manufacturer with rich experience in production. If you want to work in the plastic recycling business, feel free to leave a comment on the website.