Plastic baling machines compress, bundle, and package waste plastic products into compact, easy-to-transport, and store shapes. The plastic baler output is 1-5 tons per hour.

Introduction of Plastic Baling Machine

By using a plastic baler, plastic waste can be efficiently compressed into the desired bale size and weight. This reduces space requirements and transportation costs.

PET bottle baling machines are commonly used in plastic PET bottle recycling plants. Shuliy has vertical plastic baling machines and horizontal polystyrene balers for you to choose from.

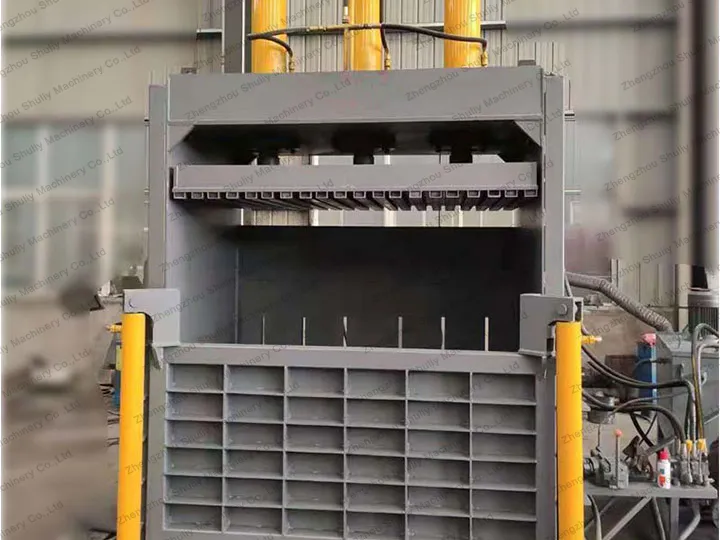

Vertical PET bottle baling machine

Shuliy vertical PET bottle baling machine is a plastic compactor that compresses plastic by applying a downward vertical force. The vertical PET bottle baling press machine is usually suitable for handling larger volumes of waste such as plastic bottles, containers, cardboard, and fibers.

When the plastic baler chamber is filled with waste plastic, the plastic baling machine’s punch moves downward and compresses the waste into tight bundles.

Advantages of vertical PET bottle baling press machines over hydraulic plastic balers include a smaller footprint, lower cost, and versatility of materials handled.

| Model | Pressure(T) | Power(KW) | Capacity(h) | Weight(T) |

| SL-60T | 60 | 60 | 1.5-2T | 1.5 |

| SL-100T | 100 | 100 | 3-3.5T | 2.8 |

| SL-120T | 120 | 120 | 4-5T | 3.2 |

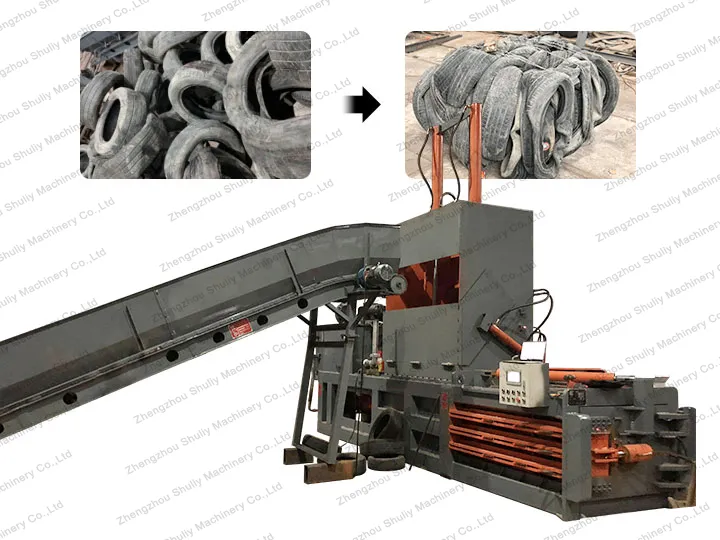

Horizontal hydraulic plastic baler

Horizontal plastic balers are horizontally arranged baling machines where waste is slid in from one side and discharged from the other side through compression and tying processes.

| Model | Power | System pressure | Feeding size | Capacity |

| SL-160 | 30kw+4kw | 1600KN | 1650mm*1100mm | 5-8 bale/h |

| SL180 | 30kw+4kw | 1800KN | 2000mm*1100mm | 6-9 bale/h |

| SL-200 | 45kw+4kw | 2000KN | 2000mm*1100mm | 8-10 bale/h |

Multi-functional PET Bottle Baling Press Machine

Shuliy plastic bag baler can be used to compress PET bottles, plastic bags, and other waste plastics in addition to oil drums, cans, tires, rubber, scrap metal, cardboard boxes, clothes, and so on. It is an all-around waste press machine.

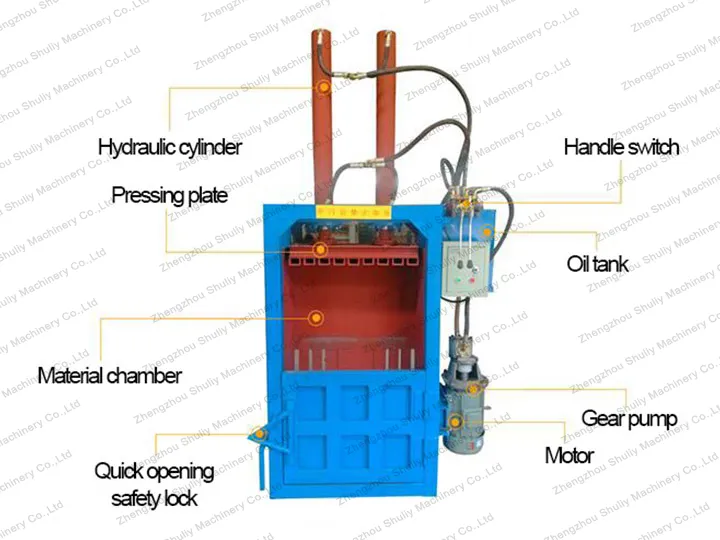

Structure of Baler Machine for Plastic

Baler machines for plastic typically include components such as hoppers, compression systems, tying systems, packaging systems, control systems, heat sealing or welding devices, discharge ports, frames, and support structures.

These elements work in tandem to realize the transformation of plastic waste into compact bales through compression, tying, and packaging. Waste plastics in the form of bricks are easy to transport and store.

Working Principle of Cardboard and Plastic Baler

Plastic baling machine mainly relies on the hydraulic system to provide pressure to compress the loose plastic waste into regular baling blocks

Feeding:

Put the plastic waste to be processed into the feeding port.

Compressing:

After pressing the control button or triggering the automatic program, the hydraulic cylinder starts to push the press plate down to pressurize the plastic waste.

Forming:

As the platen is pressed down, the plastic is gradually compressed to form a high-density rectangular block.

Packing:

After the compression is completed, the operator manually or automatically bundles and fixes the compressed block with wire or plastic tape.

Open the discharge door, and the compressed and molded plastic package is pushed out.

Main Functions of Baler Machine for Plastic

Compression function: The plastic baling machine for sale compresses loose plastic materials (such as PET bottles, plastic films, and packaging materials) into blocks by hydraulic or mechanical force.

Packing function: after compression, the compacted plastic is bundled using wire, baling tape, and other materials.

Volume reduction: Significantly reduce the volume of plastic waste and improve the efficiency of storage and transportation.

Advantages of Polystyrene Baler

Polystyrene balers offer a variety of advantages in the field of plastic waste disposal, packaging, and logistics.

- Efficiency enhancement: Plastic baling machines can convert waste plastic products into compact bales through compression, strapping, and packaging, improving the efficiency of waste disposal and packaging.

- Space saving: By compressing plastic waste into compact bales, plastic baling machines reduce the amount of space taken up by waste during storage and transportation.

- Easy to transport: Compressed and bundled plastic packages are easier to transport, reducing the volume and weight of goods in transit, lowering transportation costs, and making more efficient use of transportation resources.

Plastic Baling Machine Applicable Materials

Plastic balers are widely used in the compression and baling process of all kinds of recyclable plastic materials.

- PET plastic bottles

- Plastic film

- Cardboard boxes

- Woven bags

- Plastic drums, plastic containers

Plastic Waste Baler Helps Kenya Recycling Project

The plastic bag baler has now been successfully shipped to Kenya, and the customer has received the machine and is ready to put it into operation. They say they are looking forward to the machine’s ability to significantly improve productivity, especially when handling large quantities of plastic bales, reducing the complexity and time costs of manual operations!

FAQs of PET Bottle Pressing Machine

What are the causes of loose packing?

Insufficient pressure, untidy material placement, or untightened strapping.

What should routine maintenance include?

Cleaning equipment, checking screws, lubricating moving parts, wire inspections, etc.

Can I pack materials other than plastic?

Depending on the equipment model, some of them can pack paper, fabric, etc.

Plastic Bag Baler Quotation

If you are looking for a baler machine for plastic, please feel free to leave us a message on the website. We will contact you immediately.