The plastic film recycling line is mainly used for cleaning and recycling PP, PE film, woven bags, shopping bags, waste packaging plastic, domestic waste plastic, industrial packaging film, and industrial waste gas film with different degrees of pollution and granulation.

Shuliy Machinery is a professional supplier of plastic film recycling machinery, experienced in production, and can be customized according to your needs. Welcome to contact us.

Introduction of Plastic Film Recycling Line

The plastic film recycling line is mainly used for the regeneration and granulation of waste PP and PE woven bags, in which the most important equipment is the plastic granulator.

The layout is compact and reasonable, according to the customer’s plastic recycling plant and the actual needs of a flexible and variable layout planning site, with low energy consumption.

It can be a 24-hour non-stop safe operation, effectively reducing operating costs, to ensure that customers have low input, high-efficiency gains.

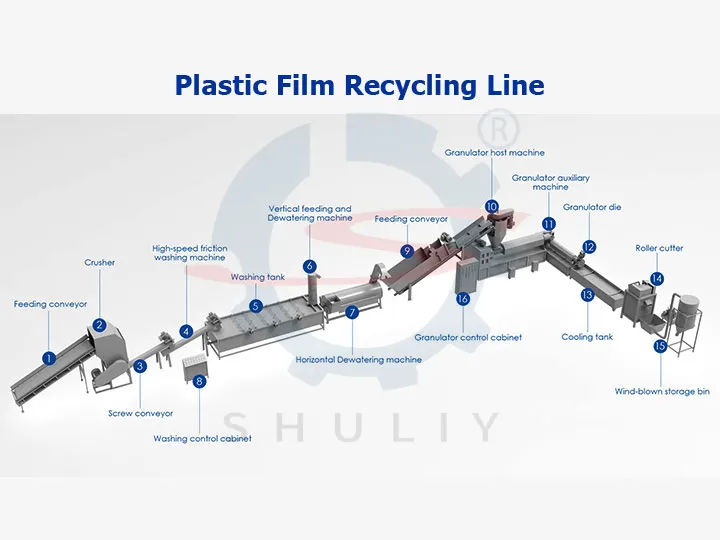

Process of Plastic Film Recycling Line

Crushing → Washing → Rinsing → Drying → Granulating → Drawing → Cutting → Packaging

First, for woven bags with large sand content, after cutting or shredding, make large rolls of woven film bags into small bundles of small piles, then screening and sand removal pretreatment, and then add water to wet crush into small fragments.

Second, the machine in the plastic film recycling line shreds film fragments through the special film woven bag high-speed friction machine strong scrubbing, removing most of the material surface sediment, and then rinses the material with water

Finally, the rinsed and separated materials are sent into the squeezing and drying machine for dewatering. After washing and drying, the film-woven bags can enter the granulator for granulation.

Raw Materials and Finished Products of Plastic Film Recycling Machine

The plastic film recycling line, also called a plastic granulation line, can cut plastic film, like plastic products and plastic woven bag-like products, into recycled plastic pellets.

This is an automated recycling system that integrates crushing, cleaning, and granulation, and through multiple processes, it converts waste plastic woven bags into recycled plastic pellets with reuse value.

As the raw material of recycled plastic, plastic granules are used in various fields of industry and people’s livelihood, which is a key material to promote the circular economy of plastics.

Main machine of Plastic Film Recycling Line

Step 1: Plastic crusher machine

Shredding and cleaning recycled woven bags, shopping bags, used plastic packaging bags, etc. Since long pieces of plastic film can easily tangle and block conveyors and rotary machines, the first step is to use a plastic shredder to cut the plastic film into smaller pieces.

Step 2: Plastic washing machine

The raffia bag washing line pays attention to washing the crushed plastic film and removing dirt from the plastic material. The water pool with a toothed agitator propels the plastic material forward to the next machine in the plastic film recycling line.

Step 3: Vertical dewatering machine

Dewatering is the most important step in a plastic film recycling system because the film is hygroscopic and pelletizing machines require film sheet moisture rates of less than 5%, the lower the better.

Step 4: Plastic film pelletizing machine

The crushed flake film is extruded and processed into plastic pellets through the extrusion system of the pelletizer, which has the characteristics of high output, good pelletizing capacity, and high compactness.

Step 5: Cooling tank

The cooling trough is used to cool the long strips of plastic extruded from the plastic pelletizer to make them cool and harden for cutting.

Step 6: Plastic pellet cutting machine

The last and most important step in plastic film recycling, the plastic pellet cutting machine is a machine which cuts long strips of cooled plastic into uniform pellets.

The specific configuration in the plastic pelletizing production line can be customized according to the customer’s budget and different requirements.

Please feel free to contact us if you want to ask any questions about the plastic film recycling line.

Features of Plastic Film Recycling Line

- The use of a circulating water system ensures the cleaning effect while controlling the water flow and evaporation of water

- Targeted design of the fine crushing system, the size of the crushed film is even and easy to clean

- The rinsing water tank adopts claw-type uniform discharge to ensure uniform discharge and control the water content at the same time, providing a process basis for the dewatering module

- The moisture content of the finished product is strictly controlled to 5%, which is suitable for high-quality granulation requirements.

- After theoretical calculations and repeated measurements, the mechanical operation details of the crushing, cleaning, and drying process are adjusted to avoid material loss due to excessive processing

- Automatic control of the whole LDPE film washing line, the system units are linked to operating, maximizing production capacity, and at the same time have a prediction function for possible abnormalities to ensure system safety

- According to the production requirements can be equipped with the corresponding plastic pelletizing lines. Welcome to contact us, and we will provide you with the perfect solution.

Global Cases of Plastic Pelletizing Line

Shuliy has provided woven bag recycling machines to several countries around the world, such as Saudi Arabia and Germany. Here are some photos of the machine as it was being prepared for shipment.

These countries turn waste plastics into reusable resources through plastic film recycling line, which not only reduces waste emissions but also creates new economic growth and employment opportunities for the local community, which is in line with the trend of sustainable development and lays the foundation for the long-term development of the enterprise.

Shuliy Plastic Pelletizing Plant Show

Shuliy plant showcases cutting-edge recycling solutions- plastic film recycling line. It highlights state-of-the-art equipment, from PET bottle recycling lines to plastic granulation systems, each demonstrating the brand’s commitment to efficiency and sustainability. With modular setups and customizable configurations, the plant show not only demonstrates machinery in action but also illustrates Shuliy’s tailored approach to meeting global recycling demands, blending industrial functionality with eco-friendly design.

FAQs of Plastic Film Recycling Line

What recycled plastic pellets can be used for?

Plastic pellets produced in plastic pelletizing lines can be used to make various plastic bags, stationery, buttons, zippers, and other household items, as well as plastic construction tools, doors, windows, and mud and ash buckets.

Plastic granules are also widely used in agriculture, such as manufacturing agricultural film, pumping pipes, agricultural machinery, fertilizer bags, and other agricultural appliances. Using PP PE recycled pellets to manufacture plastic products can save resources and reduce solid waste pollution.

What are the causes of air bubbles in recycled pellets?

The moisture content of the raw material of recycled film is more than 0.5%, and air bubbles are formed by vaporization of water during the extrusion process.

Why is the film not uniform in size after crushing?

In this plastic film recycling line, if the gap between the fixed and moving knives is more than 2mm, it should be adjusted to 1-1.5mm and ensure the parallelism.