The plastic recycling granulating line is mainly used for recycling waste plastic barrels, plastic basins, plastic chairs, plastic toys, and other hard plastics. This plastic recycling pelletizing machine integrates crushing and cleaning, drying, granulating, and bagging, and is a professional piece of equipment for recycling waste plastics.

Meanwhile, Shuliy Machinery can place and install the PP PE flake recycling line according to the customer’s requirements.

Introduction of Plastic Recycling Granulating Line

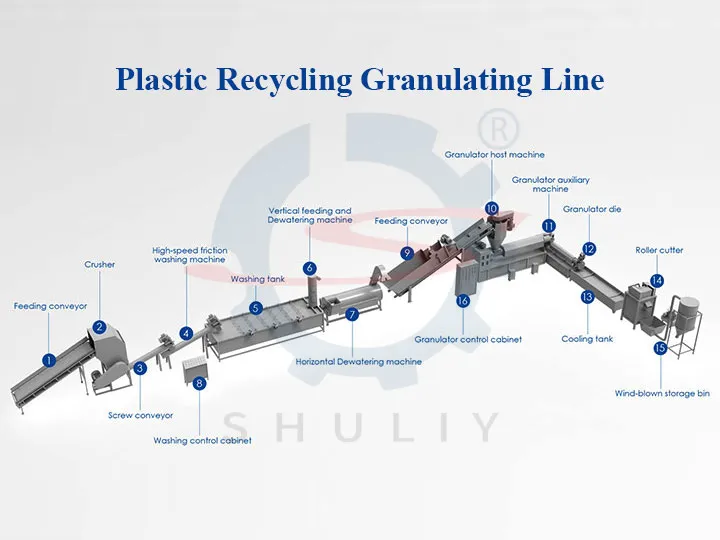

The plastic recycling granulating line mainly consists of a plastic crusher machine, a plastic rinsing tank, a plastic pellet making machine, a cooling tank, and a plastic granule cutter. The PP PE flake recycling line realizes highly automatic production, which can turn hard plastics into recycled plastic pellets and save labor.

Shuliy Machinery has focused on plastic recycling granulating lines for more than ten years and has rich experience in manufacturing plastic recycling machinery. Very welcome to visit our factory.

Plastic Recycling Pelletizing Machine Process

Crushing – Cleaning – Drying – Melting – Extrusion Granulation – Pelletizing Cutting

- Firstly, the hard plastic materials, such as waste plastic basins, buckets, and toys, are broken down into pieces and flakes through a plastic shredder machine.

- Secondly, a plastic washing machine will clear the impurities such as dust and dirt.

- Thirdly, a horizontal dewatering machine is used for dehydrating and drying plastic chips after cleaning.

- Then, the flakes firstly enter into feeding conveyor and then they are melted with electromagnetic heating to transform pieces from a solid to a molten state.

- After that, the screw inside the plastic recycling granulator is used to apply pressure to the paste, pushing it through the head die to be extruded into strips.

- Lastly, the extruded plastic is rapidly cooled down and cured through a cooling device, such as a cooling water tank or an air-cooling system, and then cut into homogeneous pellets by a pelletizing device according to a preset size.

Working Video of Plastic Recycling Granulating Line in Action

Application of Plastic Recycling Granulating Machine

Plastic recycling granulating line is a solution designed for recycling hard plastics such as plastic drums, plastic pots, plastic chairs, plastic pallets, fruit baskets, plastic containers, etc. Plastic recycling granulating line can turn hard plastics directly into recycled plastic pellets to achieve plastic recycling.

If your raw material is not covered above, or you would like to confirm its suitability for this PP and PE plastic flakes pelletizing line, please feel free to leave a message via the website. We will contact you in time.

Working Principle of Plastic Recycling Granulating Line

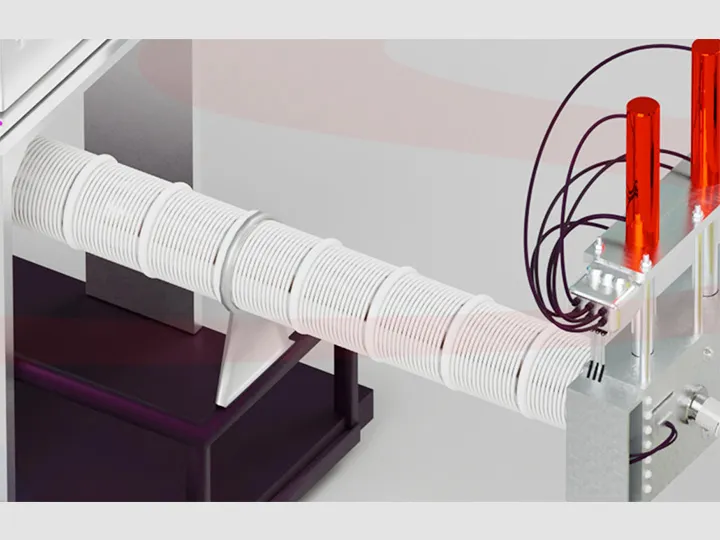

The core principle of thermoplastic molding of plastic recycling granulating line is the reversible physical properties of heating and melting and cooling and solidification with the help of plastic materials. When the waste plastic enters the granulator, the heating system warms it up to above the melting point.

After that, it is transformed from solid state to viscous fluid melt, and then the screw rotates and pushes the pressure, so that the melt is uniformly plasticized and extruded through the die。

Finally, it is rapidly cured in the cooling system, and finally cut into pellets according to the specifications by the plastic strip cutting machine.

The whole process of the plastic recycling granulating line is only a physical phase transition without chemical structure destruction, thus realizing the recycling of waste plastics.

Main Machine of Plastic Waste Recycling Plant

Step 1: Plastic shredder machine

The plastic shredder machine can easily crush hard plastics into small-sized materials, thus reducing transportation costs and facilitating subsequent plastic pelletizing.

Step 2: Plastic washing machine

The plastic washing machine is used to rinse the crushed materials with the spiral device at the bottom to remove the sediment and other impurities and further ensure the cleanliness of plastic chips and improve the quality of recycled pellets.

Step 3: Horizontal dewatering machine

The horizontal dewatering machine is used to dry the cleaned materials. Because the moisture on the material will lead to bubbles in the melt and affect the quality of granulation, the waste must be dried before processing.

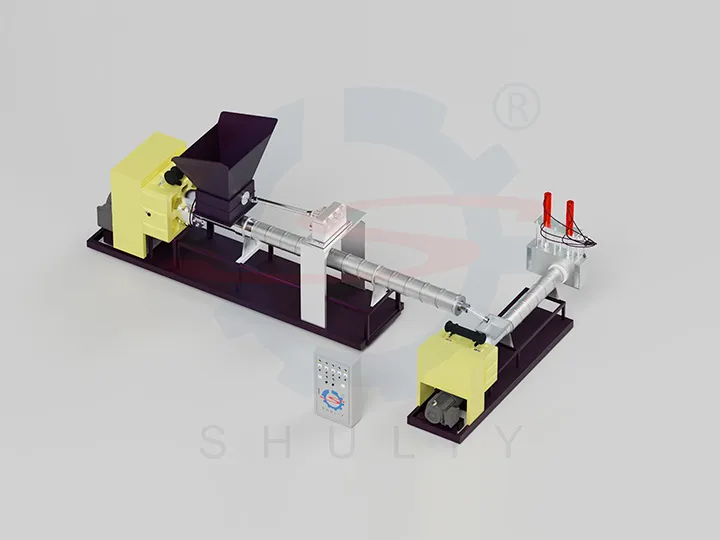

Step 4: Plastic pelletizing machine

The crushed and dried material is melted in the plastic pelletizing machine and extruded into long strips through the die head. The plastic pelletizer machine is the most important equipment in the plastic recycling pelletizing line.

Step 5: Plastic Strip Cutting Machine

The plastic strip cutting machine cuts long strips of cooled plastic into small, uniform pellets. Various machine models are available to meet different output requirements.

The exact configuration of the machine can be adapted to your needs. You are welcome to contact us for specific questions about the plastic recycling granulating line.

Why Buy Our Plastic Recycling Pelletizing Machine?

- Plastic pellets produced in plastic recycling pelletizing machines are of high quality, have no air bubbles, are full and round, and the size and thickness of the pellets cut out by the plastic pellet cutting machine can be adjusted.

- The crushing system adopts a wear-resistant design to ensure the long-term, continuous, and stable operation of the system

- High-speed centrifugal cleaning system with a suitable rotating speed for different materials to apply the corresponding blade hitting strength, good cleaning effect

- The plastic recycling pelletizing machine is controlled automatically and is a fully automatic assembly line, which realizes the direct transformation from waste plastic to finished pellets.

- About the screw barrel, it is made of imported high-strength carbon structural steel, which has the feature of durability.

- The appearance of the machine is beautiful and elegant, and it can be painted according to the customer’s requirements.

FAQ of plastic flake pelletizing line

What is the difference between PP and PE plastic?

First of all, the composition of the two is different; the main component of PP plastic is polypropylene, and PE plastic is the main component of PE plastic is polyethylene.

Secondly, the characteristics of PP and PE plastic are different. PP plastic strength, stiffness, and hardness heat resistance are better than PE and can be used at about 100 ℃. Has good dielectric properties and high-frequency insulation and is not affected by humidity, but at low temperatures becomes brittle, not wear-resistant, and easy to age. PE plastic extensibility, tear-resistance and impact resistance, high transparency, heat sealing, and processing performance.

What is the function of a horizontal dewatering machine?

Because if water is left on the surface of the plastic pieces, the water will be vaporized into bubbles by heat, resulting in the production of pellets with bubbles, voids and other defects, seriously affecting the quality of the pellets.

Can the plastic recycling granulating line produce granules of different sizes?

We can provide you with different models of machines according to your actual production needs, so that you can produce plastic pellets of the size you need.

Inquiry about Plastic Pelletizing Line

We have specialized plastic recycling equipment for sale, all at wholesale prices. If you want to set up a plastic waste recycling plant, please leave a message on the website. We can help you.

Shuliy PP PE Flake Recycling Line Factory Show

Cases of PE Plastic Flakes Pelletizing Line Exports

A 1 ton/hour capacity plastic pelletizing line from Shuliy Group has been successfully installed in Saudi Arabia.

The plastic recycling granulating line can process raw materials such as plastic film to produce recycled plastic pellets. The main equipment includes a crusher, a granulator, etc., which was installed by Schulich engineers on site.

Shuliy provided customized capacity, machine color, and a one-year warranty, and also supported the project with transportation protection and on-site technical guidance to meet the customer’s high output requirements with the plastic recycling granulating line.