How to utilize PET bottle washing plants to reduce plastic consumption has been a topic of constant discussion. What is a PET bottle scrap washing machine and what happens in the process of a PET bottle washing plant? Today, we’re going to share with you the process of a PET bottle recycling plant.

What is PET recycling?

PET, or polyethylene terephthalate, is a compound that makes up single-use plastics. Many of our household items are PET. Things we see in the supermarket such as water bottles, milk jugs, and detergent bottles all contain some amount of PET, and these can be recycled in PET bottle scrap washing machines.

PET bottle recycling lines are processes that extend the life of single-use plastic bottles. But we can’t recycle all plastics. Some plastic bottles change chemically over time. And bottles can leak chemicals or harbor bacteria that can make us sick.

Working process of PET bottle washing plant

Label removing

As we all know, PVC in waste recycled PET bottles mainly exists in the form of label paper. Since PVC and PET are the same as submerged material, it is necessary to remove PVC before crushing and processing in order to ensure the quality of recycled bottle flakes.

Crushing

Plastic crushers tear plastic bottles into pieces. This makes plastic bottles easier to wash and recycle.

Separate

Plastic bottle cap belongs to PP type and PE type material, which is different from PET bottle material. So it is necessary to separate the cap from the bottle.

Washing

The PET bottle washing plant has a lot of washing processes, which is to get clean and high-quality plastic bottle flakes. The crushed PET bottles go through hot water washing, friction washing, and rinsing process. During this process, they go to the deep cleaning stage. The goal is to remove all labels, all glue residues and to sterilize everything.

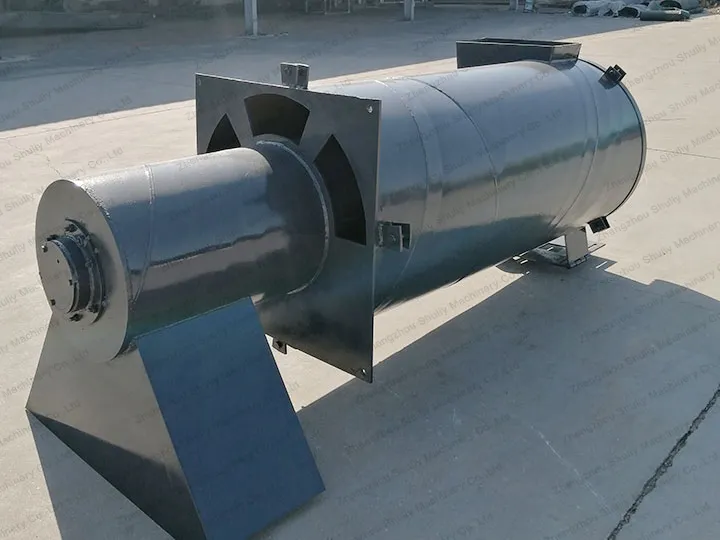

Drying

Moisture refers to the moisture content of PET bottle flakes, which is definitely the less moisture the better. Therefore, it is recommended that PET bottle washing plants purchase a plastic dryer to remove moisture from PET bottle flakes.

Inspection of PET flakes

Once all the bottles have been crushed and washed in a PET bottle scrap washing machine, the testing begins. Each batch of rPET is tested to see if they meet food-grade standards. If they pass, they can be used to make bottles or other types of food containers again. Sometimes they are also turned into straws or take-out food containers.

If the flakes don’t meet food-grade standards, the company sells them to factories in other countries. Once there, they are turned into everyday household items such as welcome mats, pillow stuffing, or clothing

If you want to know more about PET bottle washing plants, please contact us or visit our website to learn more.