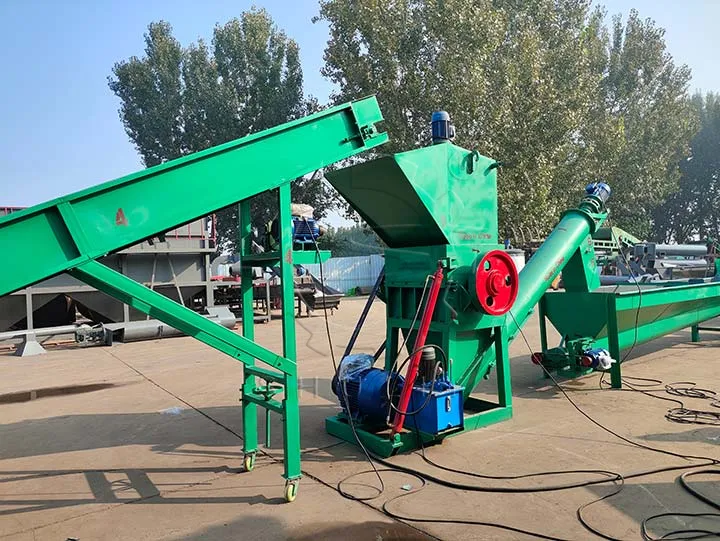

The usefulness of the HDPE shredder machine is gradually expanding. As customers often neglect the maintenance of bearings resulting in machine failure and inability to operate normally. This blog provides you with some tips to extend the life of plastic lumps shredder machine bearings for reference.

Checking HDPE shredder machine parts

Before installing the large plastic shredder, carefully count the number of parts and check the threads of each part for damage. Carefully remove any damage caused during loading and unloading handling.

Proper use of lubricants

After the plastic lumps shredder machine bearings are installed, be sure to coat the bearings with lubricant to cover all roller surfaces. Normally cover the large plastic shredder with plastic film to protect it from dust.

Cleaning and lubrication of bearings

Clean the HDPE shredder machine bearings regularly in daily use. Put the bearings into oil and remove the dirt on the bearing surface with a brush. For the ball and loophole inside the plastic lumps shredder machine, the bearing should be cleaned in detail.