The automatic feeding machine, also known as a forced feeder, is a common plastic granulator auxiliary equipment, which is usually used with soft material plastic granulators. Its main function is to feed the raw materials into the inlet of the plastic pelletizer automatically in order to realize a continuous and stable production process.

Automatic Feeding Machine Introduction

The forced feeder is an essential piece of equipment designed to improve the efficiency and accuracy of material handling in industrial production lines. It integrates a reinforced steel hopper, a chain-driven conveyor, and a precision gearbox-motor system to ensure continuous, stable feeding of bulk, irregular, or heavy materials. The machine is widely used in industries such as plastics recycling, metal processing, and automated assembly, helping manufacturers reduce manual labor and enhance production consistency.

Our automatic feeder system features a compact, durable design with modular options for easy integration into various production environments. Equipped with sensors and PLC control, it offers intelligent feeding cycles, jam detection, and auto-stop functions for safety and efficiency. This smart feeding solution not only optimizes workflow but also supports green manufacturing by minimizing waste and energy consumption.

Automatic feeding machine working principle

The working principle of the automatic feeding machine is to automatically feed the pre-stored raw materials in the silo into the inlet of the plastic granulator through mechanical transmission and control system. This enables a continuous and stable supply of raw materials, thus improving production efficiency and quality. Different types of forced feeders may differ in specific transmission methods, control systems, and other aspects, but the core principle is similar.

Main Components of the Automatic Feeding Machine

Our automatic feeding equipment consists of several key components that work together to ensure reliable and efficient feeding performance:

| Structures of forced feeder | Function |

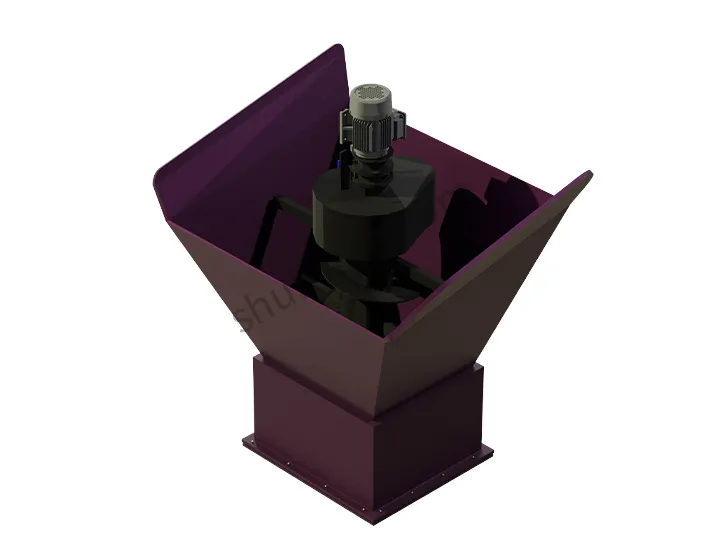

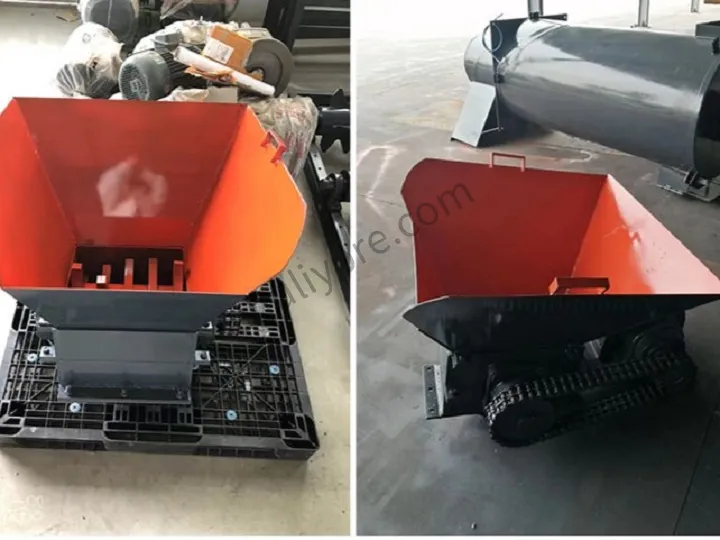

| Reinforced Feeding Hopper | The large-capacity hopper is fabricated from thick steel plates with reinforced edges. Its steep angles ensure smooth material flow, preventing bridging or blockages. |

| Heavy-Duty Chain Conveyor Mechanism | With a rugged chain drive system, visible on the side, the chains and sprockets are made from hardened steel, ensuring durability and resistance to high loads. |

| Gearbox and Drive Motor | The forced feeder is equipped with an industrial-grade motor coupled with a gearbox to control speed and torque precisely. This ensures consistent feeding even under varying material loads. |

How the Forced Feeder Works

- Material Loading into Hopper: Raw materials are loaded into the hopper, which serves as a temporary storage and feeding reservoir.

- Material Conveying by Screw: The motor drives the feeding screw to move materials forward continuously and evenly.

- Material Discharge to Next Stage: Materials are pushed out of the feeder into the downstream equipment for further processing

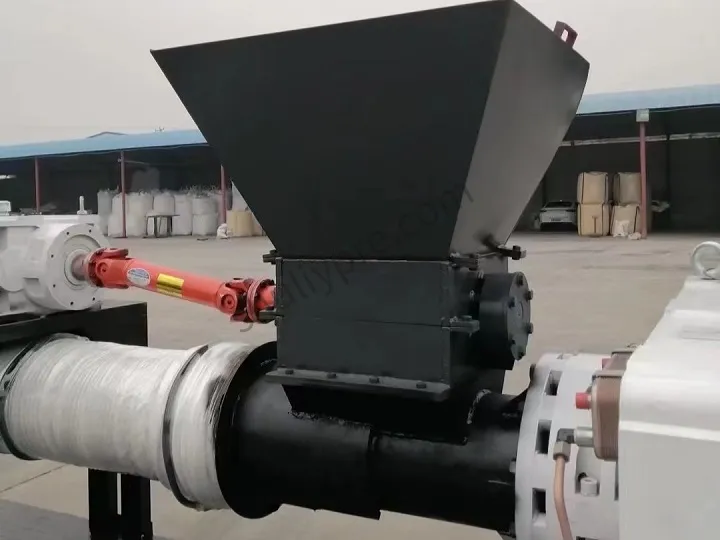

- Model: SL-150

- Power: 5.5KW

- With a reducer, a control cabinet, and a drive shaft

Forced Feeder: A Vital Component of the Granulating System

The automatic feeding machine plays a crucial role in the granulating line by ensuring a consistent and controlled supply of raw material into the granulator. Without a reliable forced feeder, the entire production process can be disrupted, affecting product quality and efficiency.

In a typical granulating system, the forced feeder works in coordination with:

Woven Bag Granulator Machine

The plastic film recycling machine heats and plasticizes these plastic bag materials, and then extrudes and cuts them into uniform pellets through the die.

Cooling Tank

The plastic cooling machine is used to cool the soft plastic long strips extruded by the pelletizer auxiliary machine for easy cutting by the plastic pellet cutting machine.

Plastic Pellet Cutting Machine

The plastic granule cutter cuts and melts raw plastic materials into uniform pellets.

Why do you need a forced feeder?

The characteristics of lightweight and soft materials, such as plastic films, make them prone to flying apart, have uneven build-up, and are even difficult to accurately feed into the pelletizer when manually feeding. In this case, an automatic feeding machine can solve many of the problems associated with manual feeding, improve production efficiency, and ensure the stability and quality of the pelletizing process.

Advantages of a forced feeder

- Prevention of fly-away and build-up: Lightweight materials such as plastic film tend to fly apart when fed manually. Forced feeders reduce scattering and buildup by controlling the speed and manner of feeding.

- Uniform feeding: The automatic feeding machine ensures that plastic film and other materials enter the feed inlet of the granulator uniformly, avoiding the problem of uneven feeding by hand.

- Accurate control: The forced feeder is equipped with a precise control system that adjusts the feeding speed and volume as needed for accurate feeding control.

- Increased productivity: Automatic feeding machines increase productivity by providing a continuous, consistent supply of material and reducing downtime due to manual feeding.

FAQs of the forced feeder

How to prevent forced feeder jamming?

Keep material dry, adjust feeder speed properly, and ensure uniform particle size.

What is the difference between a forced feeder and a gravity feeder?

Forced feeders use mechanical force to push materials, while gravity feeders rely on gravity flow.

Is pre-treatment needed before feeding materials?

Depending on the material, drying, size reduction, or sieving may be needed to ensure smooth feeding.