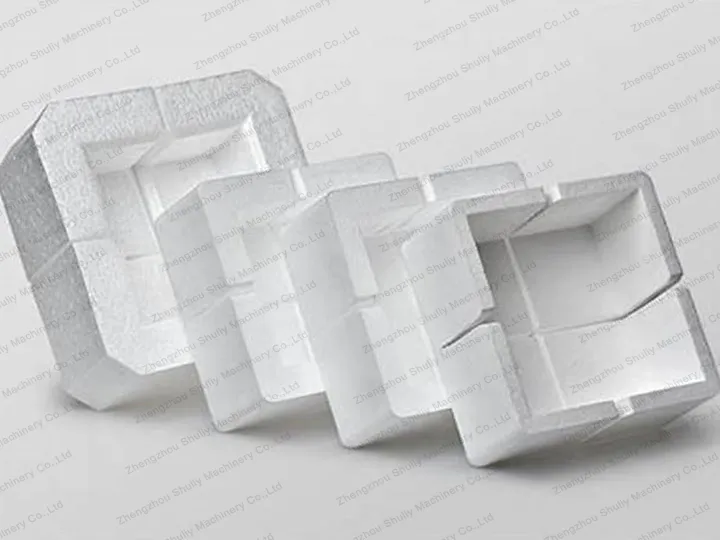

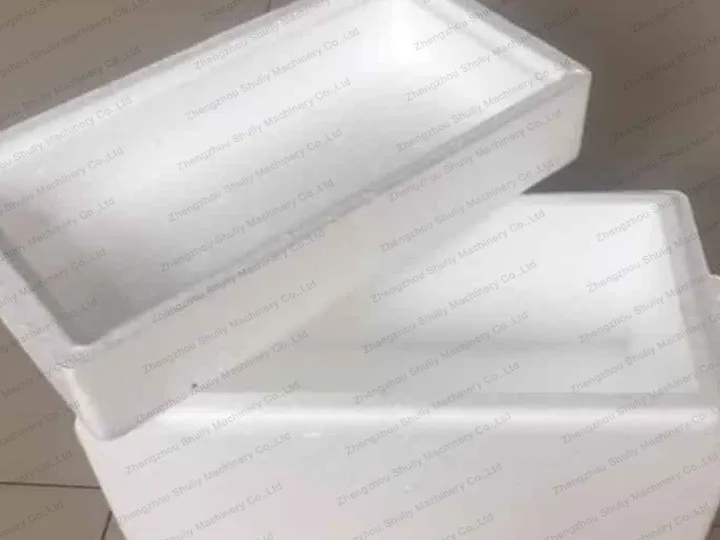

The EPS pelletizing machine is suitable for EPS and other foam regeneration granulation. It is mainly for the regeneration and granulation of foam boxes, foam boards, and foam corner protectors. This kind of recycled plastic granules can manufacture all kinds of stationery, toys, electrical appliance shells, etc.

Introduction of EPS pelletizing machine

The EPS pelletizing machine is a special machine for crushing and granulating waste foam and pearl cotton. The EPS granulator has a reasonable design, a high degree of automation, and advanced technology. The pellets produced are widely used and in short supply in the market, with users all over the world!

The EPS pelletizing machine recycles waste EPS into reusable pellets via crushing, melting, extrusion, and pelletizing. Featuring energy-efficient heating and durable screws, it suits various waste densities, supporting circular economy in packaging and construction.

Principle of EPS granulator

The principle of the EPS pelletizing machine is very simple. The foam granulator uses a motor to drive a reducer to push the material forward. The foam is melted under the action of an external heating device and then becomes recycled pellets through a series of processes. The EPS pelletizing machine is the most important in the plastic foam granulating line.

Parameters of EPS granulation machine

| Type | Capacity | Main Motor |

| 220 (double reducer) | 150-175kg/h | 15kw |

| 270 (double reducer) | 200-225kg/h | 18.5kw |

| 320 (double reducer) | 275-300kg/h | 18.5kw |

If you want to know more information, please leave us a message on the website, and we will contact you in time!

Main Parts of EPS Recycling Machine

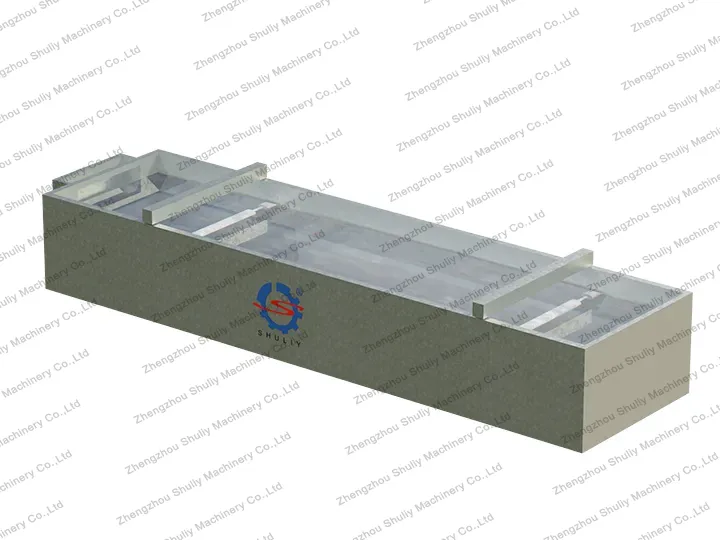

Feeding conveyor

It utilizes the synergy of mechanical transmission and material conveying to achieve directional material conveying by driving the reducer through the motor, which in turn drives the conveyor belt, screw, and other conveying parts to operate.

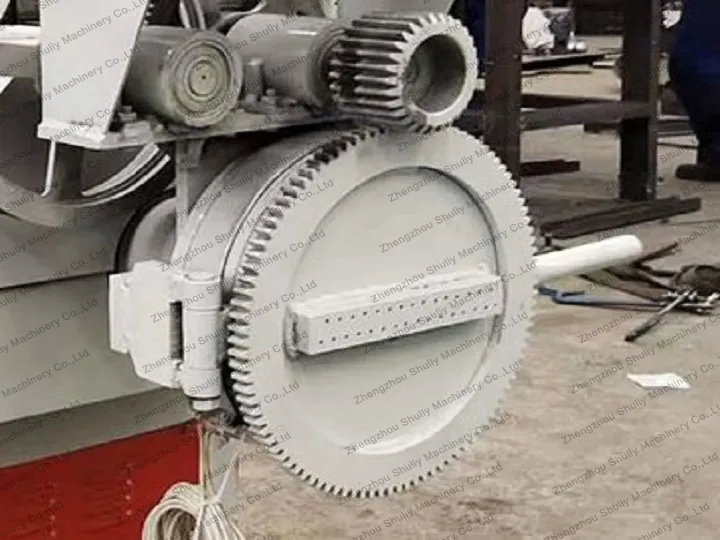

Die head

The internal shape of the die head allows the plastic in its molten state to pass uniformly through the die holes to form a specific-shaped stock strip.

Heating ring

Heating rings precisely convert electrical energy into thermal energy, providing stable temperature support for industrial equipment

Solution on Styrofoam Recycling Machine Line

In modern industrial production, the synergistic operation of an entire EPS pelletizing machine offers incomparable advantages. When the various parts of the EPS pelletizing production line, such as the crusher, melt extruder, pelletizer, etc., form an organic whole, the material from the waste foam input to the output of the finished pellets of the whole process realizes a seamless connection.

This EPS pelletizing machine not only increases production capacity by more than 30%, but also reduces labor input by nearly half through automated conveying and integrated operations, eliminating the need for workers to travel back and forth between multiple machines.

It rapidly reduces the temperature of molten plastic through cooling water to solidify and shape it, avoiding deformation, stringing, or dimensional deviation caused by excessive temperature.

Plastic Granule Cutter Machine

The Plastic pellet cutting machine cuts the long strip into small particles.

It is a key buffer unit in the plastics processing process, mainly used for the temporary storage of produced granules.

The specific configuration of the EPS foam granulating line can be adjusted according to your needs. If you have this need, please feel free to contact us!

Foam Granulator Features

- Adopting the main and secondary machines to support the production, the heating temperature is stable, which effectively improves the molecular structure of the material and enhances the air permeability, and the quality of the granules is improved!

- The EPS granulation machine unit is mainly composed of a crusher, main machine, and automatic traction cutting machine, and the main machine adopts an automatic net changing device.

- Main and secondary machine screw barrels are made of high-strength carbon structural steel.

- The foam granulator adopts a conical screw barrel, with fast feeding speed and high output.

How to Operate Plastic Foam Granulator?

There are two heating circles on the upper and lower screw of the foam granulator, and each heating circle has a switch, which can be opened and closed at will according to the temperature needed for processing.

When the EPS high-speed granulator is working, the upper and lower barrels are heated for 20-40 minutes, then take a piece of foam on the head and press it lightly. If the foam becomes soft and melts, it means that the barrel heating has

reached the working temperature (about 180 degrees) and the machine can be turned on.

In the foam granulator work, the lower screw head can add a layer or two layers of 20-80 mesh filters or another suitable number of filters as needed (the higher the mesh filter impurities, the cleaner the filter). There should be more than one strainer. If the work is not smooth, it means that the screen is clogged, and the screen should be replaced in time.

EPS Pelletizing Machine Exported to Malaysia

The EPS pelletizing machine exported to Malaysia this time has been carefully designed and strictly controlled, with high efficiency and stable performance.

The client in Malaysia has rich experience and clear needs in the field of plastic foam recycling, and our EPS pelletizing machine can efficiently convert the waste EPS foam into reusable granules, which greatly meets its business needs for resource recycling and reuse.

Previously, the sales team won the customer’s full trust by providing detailed pictures and videos of the equipment and answering questions promptly.

At present, the EPS pelletizing machine has been packed and shipped smoothly, and we look forward to its use in Malaysia to help the local plastics recycling industry reach new heights.

FAQs of EPS Foam Granulating Line

What if the temperature is too high or too low?

Too high causes carbonization; too low leads to poor forming or blockage.

Common reasons for extruder blockage?

Impurities, improper temperature control, or worn screw.

What happens if cooling water is insufficient?

Poor pellet formation, potential sticking, or deformation.