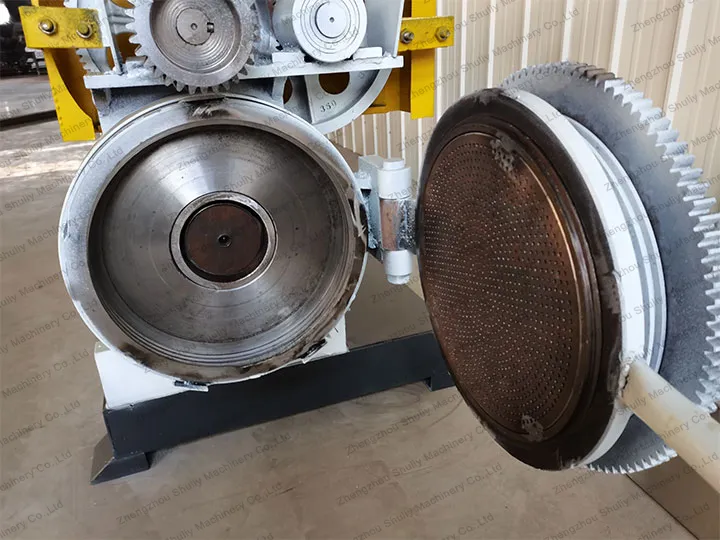

What should I do if there are black spots in the granulation of the extrusion pelletizing machine? It is a relatively common problem to encounter black spots on the granules produced by the plastic film granulator. How to solve this problem? Is this phenomenon caused by the plastic recycling pellet machine, the problem of the raw material, or other factors? Here is an analysis for you.

Why is there a black spot?

Due to the different sources of waste plastics, impurities and additives of different compositions are often mixed in them. This leads to a lot of problems that often occur during the processing of extrusion pelletizing machines. The black spot problem is the most common problem in plastic recycling and granulation. For light-colored products, their use can be affected by the presence of black spots. The causes of black spots on products are not only the raw material itself but also the following reasons.

Partial overheating of the plastic film granulator screw

Partial overheating of the screw of the granulator will lead to localized high temperature of the material, which will lead to carbonization of the material. These carbides will be carried into the plastic lengths, thus forming black spots.

Plastic recycling pellet machine die head pressure is too high

Too much pressure in the head will lead to increased material reflux, which will seriously lead to the carbonization of the material in the head and the formation of black spots.

Extrusion pelletizing machine aging

As the plastic film granulator is used for a longer period of time, the gap between the screw and the barrel will increase. When a large amount of material is retained in the gap for a long time, it will lead to carbonization and the formation of black spots.

Dirt at the die head of the plastic granulator

Extrusion pelletizing machine outlets that are not smooth or have damaged original threaded sections can cause material buildup and carbonization to form black spots.

How to avoid black spots when working with extrusion pelletizing machine?

In order to quickly clean the carbide in the plastic recycling pellet machine, engineers have proposed a new method: cleaning with hard plastic or recycled material plus white mineral oil. At the same time, the temperature of the extrusion pelletizing machine is appropriately increased by 10~15℃. During the cleaning process, the plastic film granulator is repeatedly switched between low and high speeds to ensure the complete removal of carbides. If the carbide in the plastic recycling pellet machine is significantly reduced, the available plastic can continue to clean until clean. At this point, the extrusion pelletizing machine can be gradually adjusted to the appropriate temperature, you can normal production.

During the cleaning process, the extrusion pelletizing machine can be stopped and restarted several times. By adhering to this solution, many manufacturers have succeeded in reducing the black spot problem and improving plastic film granulator productivity and plastic pellet quality.

More information about extrusion pelletizing machines can be obtained by visiting our official website https://shuliypre.com/ Of course, you can also contact me directly!