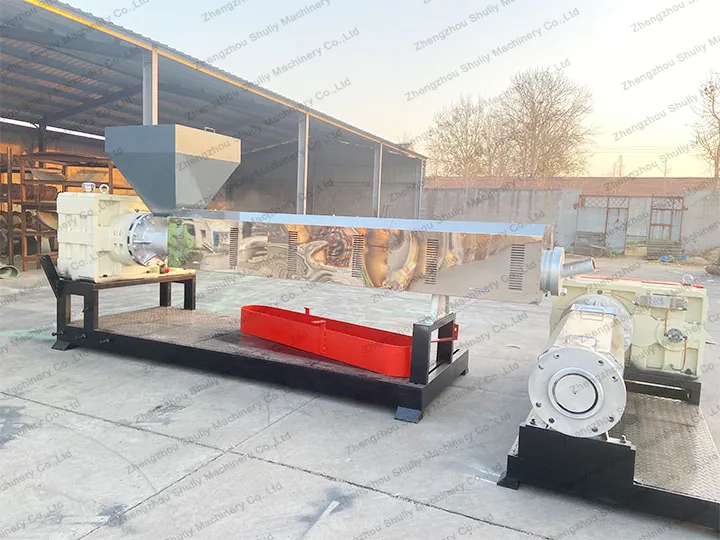

As an important processing component, the granulator machine screw plays an important role in the extrusion and pelletizing process. However, prolonged use and operation in high-temperature environments can lead to screw wear, affecting plastic recycling extruder machine performance and product quality. So how to improve the wear resistance of the waste plastic recycling pelletizing machine screw? Read on.

Granulator machine screw wear reasons

The main causes of granulator machine screw wear include feedstock characteristics, high temperature and pressure environments, screw material, and design. Certain raw materials contain hard particles or additives that can increase screw wear. At the same time, a high temperature and high-pressure environment will make the plastic recycling extruder machine screw subject to high friction and thermal expansion, accelerating wear. The material and design of the plastic recycling extruder machine screw will also affect its wear resistance and service life.

Dangers of plastic recycling extruder machine screw wear

Screw wear is harmful to the granulator machine in many ways. Firstly, screw wear will lead to lower extrusion efficiency of the waste plastic recycling pelletizing machine, affecting production efficiency. Secondly, the loss of smoothness of the screw surface may lead to a decrease in pelletizing quality, uneven particle size and irregular shape, and other problems. In addition, granulator machine screw wear will also increase energy consumption and maintenance costs, shortening the service life of the equipment.

Granulator machine screw wear solution

To improve the wear resistance of the granulator machine screw can choose high-quality alloy steel material to manufacture the screw and improve its anti-wear performance. Secondly, use a surface coating or a hard plating process to increase the hardness and wear resistance of the screw surface. Regular inspection and maintenance of the screw and timely detection and treatment of wear and tear is also effective way to delay the waste plastic recycling pelletizing machine screw wear.

For slight wear and tear, repair techniques, such as grinding and welding, can be used to restore the plastic recycling extruder machine screw to its normal shape. And for serious wear and damaged screw, it should be replaced with a brand new one in time to ensure the normal operation of the granulator machine.