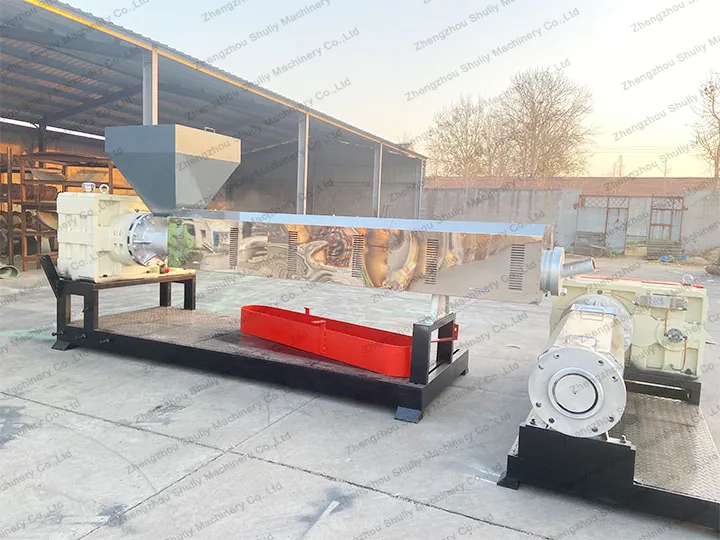

The Pelletizer machine is an important piece of equipment in a plastic recycling production line. Reasonable shutdown procedures are very important to ensure the safe operation of the waste plastic granulator machine and extend its service life. Do you know how to turn off the pellet extruder machine correctly when the plastic recycling line stops? Read on!

Stop pelletizer machine feeding

When trying to get the pelletizer machine to shut down, you first need to stop the feed system of the waste plastic granulator machine. Shutting down the feed system is to ensure that the pellet extruder machine is no longer receiving new material.

Stop heating waste plastic granulator machine

Depending on how the pellet extruder machine is heated, stopping the heating system is designed to allow the equipment to cool down gradually. In this way, the heating elements are protected from overheating and damage.

Cleaning the inside of the pelletizer machine

After shutdown, clean the remaining raw material and recycled pellets from inside the pellet extruder machine. This prevents material buildup and clogging and keeps the equipment clean. Thorough cleaning and maintenance of your pelletizer machine is very important. Keeping the waste plastic granulator machine clean will help improve its operating efficiency and production quality.

Inspection of pellet extruder machine components

After stopping the machine, check the key parts of the pelletizer machine. Ensure that they are intact, and if abnormalities are found or there are parts that need to be replaced, repair and replace them in time. It is recommended to record the data related to the operation of the equipment, such as output, temperature, pressure, and so on. These data help subsequent production management and analysis. When stopping the machine, it is also necessary to turn off the auxiliary equipment connected to the pellet extruder machine, such as plastic dryers, conveyors, etc. Make sure that all related equipment has stopped running.