Plastic film pelletizing machine is a kind of plastic recycling equipment, which converts plastics into granular materials by heating, compressing, and extruding them.

Plastic granulator is suitable for all kinds of plastic raw materials, including PP, PE, HDPE, LDPE, PVC, PS, etc. The final product is recycled plastic pellets.

Shuliy plastic film recycling machine has a wide range of output, from small 150 kg/h to large 1000 kg/h.

Introduction of Plastic Film Recycling Machine

Shuliy’s plastic film pelletizing machine features a special double-step screw design, suitable for producing pellets from PP, PE, ABS, PVC, PC, PET, and other plastics through recycling.

The screw and barrel are specially hardened to provide wear resistance, good mixing performance, and high output.

Working Video of PE PP Plastic Film Recycling Line

How Does Plastic Become Plastic Pellets through Woven Bag Recycling Machine?

The plastic film pelletizing machine is equipment used to process plastic waste or raw materials into granules. The following is the basic process by which plastic is processed into plastic pellets by a plastic film granulator.

- Feeding: First of all, the plastic waste or raw material will be fed into the feeding port of the plastic film pelletizing machine. Film-type soft plastics need to be fed with the aid of an automatic feeder.

- Melting and Plasticizing: Through the electric heater or other heating methods, the plastic material inside the barrel will be subjected to high temperature, and gradually soften and melt.

- Extrusion: Once the plastic has reached a sufficient level of plasticization, it is pushed into the extrusion screw inside the barrel.

- Cooling and Curing: The newly formed plastic pellets are passed through a cooling system, usually water, to rapidly cool and cure the pellets.

- Cutting: After the pellets are formed and cured, they are cut by a plastic pellet cutter machine.

Parameters of Plastic Film Pelletizing Machine

| Model | 150 | 180 | 200 | 220 |

| Screw diameter | 150mm | 180mm | 200mm | 220mm |

| Spindle speed | 40-50/min | 40-50/min | 40-50/min | 40-50/min |

| Main motor power | 37kw | 55kw | 75kw | 90kw |

| Reducer | 250 | 280 | 315 | 330 |

| Output | 300kg/h | 350kg/h | 380kg/h | 420kg/h |

These types of outputs can meet most people’s production needs. Of course, we can also provide plastic film pelletizing machines with larger or smaller outputs.

If you need a plastic film recycling machine with other capacities, please feel free to leave your contact information on our website. We will contact you immediately to customize a plastic solution for you.

Plastic Film Recycling Machine Line Solution

A plastic film recycling machine is usually combined with a waste plastic crusher, a plastic washing machine, a cooling tank, and a pelletizer to form a production line for processing waste film materials.

The stretch film recycling line, combining recycling machines, shredders, washers, cooling tanks, and a cutting machine, achieves 300% higher processing efficiency than standalone equipment. For example, automated cutting reduces manual preprocessing time by 70%, while continuous washing-extrusion-pelletizing cycles eliminate material downtime. This streamlined workflow enables industrial lines to convert 1 ton of waste film into marketable pellets within 4 hours, critical for meeting high-volume recycling demands in e-commerce and agricultural sectors.

If you’re interested, please feel free to contact us. We will recommend the most suitable plastic pelletizing solution for you! Please feel free to contact us!

3 Types of Die Heads for Plastic Granulators

There are three common types of plastic pelletizer die heads: electric gear die heads, hydraulic die heads, and automatic slag filter die heads.

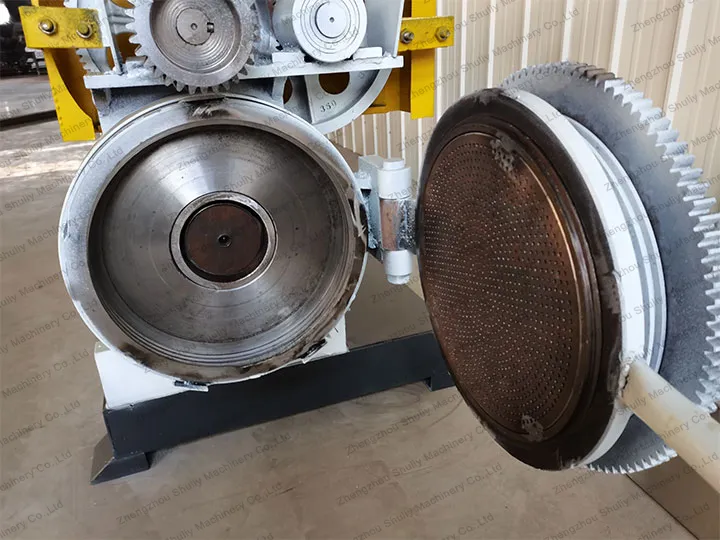

Electric gear die head

An electric gear die head is a type of die head commonly used in plastic pelletizing machines. It transmits rotational power to the screw using an electric motor-driven gear transmission system, which pushes the plastic material into the extrusion screw for the plasticizing and extrusion process.

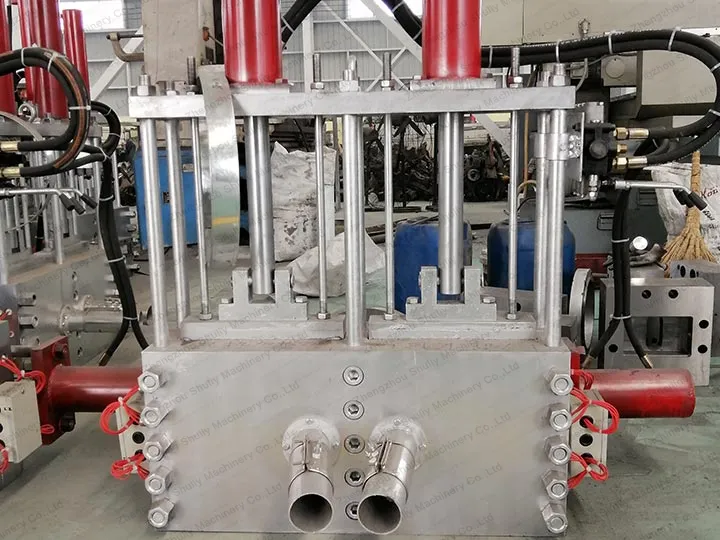

Hydraulic die head

The hydraulic die head in plastic pelletizing line realizes the plasticizing and extruding process of plastic by pushing the plastic material into the screw of the extruder with the force provided by the hydraulic system.

This type of die head is suitable for handling high-viscosity and high-hardness plastic material with strong adaptability and stability.

Automatic slag filter die head

The automatic slag filter die head is a specially designed die head for plastic film granulators. Through the special structure of the screw and the slag discharge port, the plasticized plastic material is discharged from the die head without the need for an additional strainer.

The automatic slag filter die head effectively avoids the clogging of the mesh, which may affect the production efficiency, and simplifies the cleaning and maintenance process.

Raw material of Plastic Film Pelletizing Machine

Shuliy plastic film granulators can process different types of plastics such as plastic film, agricultural film, woven bags, HDPE bottles, raffia bags, and so on.

Here we only list some of the raw materials. If you are not sure which plastic granulator is suitable for your raw material, please feel free to contact us to ask.

Plastic Pelletizing Machine Price

Shuliy plastic film granulator prices range from a few thousand dollars to tens of thousands of dollars. Prices vary for different models and outputs of granulators. Please contact us via WhatsApp or message us directly on the website for a specific quote.

Features of Our Plastic Granulators

- Customization: the machine offers a wide range of models and specifications with output capacity ranging from 300-420 kg/h, which can be customized according to users’ requirements.

- Reinforced wear-resistant parts: screw and barrel are treated with special hardening treatment to resist abrasion and guarantee long-term high-load production.

- Safe power distribution design: Split automatic power distribution system guarantees the safe operation of the motor and reduces the risk of failure.

Precautions for Plastic Film Pelletizing Machine

- The gear oil of the new machine of the plastic film pelletizing machine should be replaced at least once every six months, and the active parts should be lubricated at least once a week

- The temperature of plastic granulator must reach the set temperature before pouring in the cleaning material or raw material to clean the residue in the screw until the new material is extruded, then suspend the extrusion and install the filter plate and die head quickly in place

- After closing the die head, turn on the main screw motor of the plastic pelletizer, the operator is away from the die head at this time to prevent the die head from being blocked by hard material and bursting and injuring people.

Successful cases of Agricultural Film Recycling Machine

We are proud to announce that our plastic film recycling machine has been successfully exported to many countries such as Mozambique, Saudi Arabia, Cote d’Ivoire, etc. We have introduced the granulation business of these customers in our previous cases. These customers have made considerable profits by utilizing our plastic film granulators.

Plastic granules making machine ready for shipping

FAQs of Plastic Film Pelletizing Machine

What causes particle sticking after cooling?

Causes: Inadequate cooling or mismatched pelletizing speed.

Solutions: Increase cooling air/water flow, add antisticking agents (e.g., talcum powder), and coordinate pelletizing and extrusion speeds to prevent melt accumulation.

How to troubleshoot abnormal noise during equipment operation?

If unusual noise occurs in the screw or gearbox, check the gap between the screw and barrel for metallic foreign objects, replace gearbox lubricant, inspect bearing wear, and adjust the concentricity of the transmission system to reduce vibration.