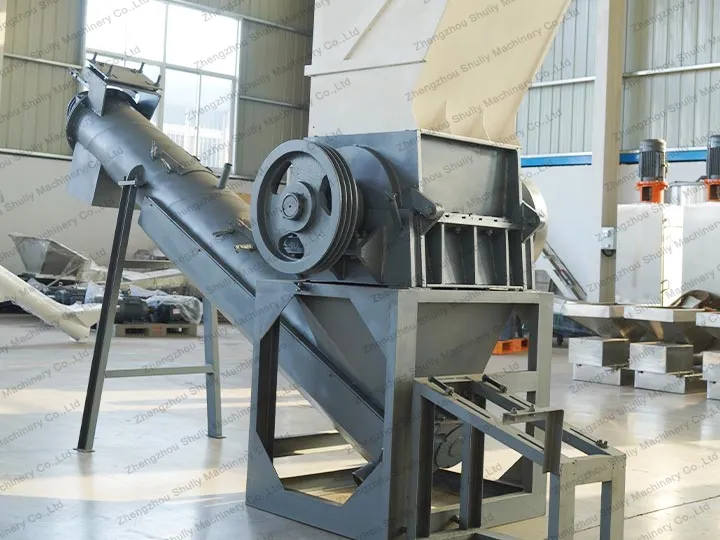

Plastic industrial shredder is a kind of high-speed extrusion cutting type crushing equipment, through the crushing chamber of the moving knife and the fixed knife with the mutual shear force between the plastic to be crushed and cut. Adding too much material at one time may lead to plastic industrial shredder jamming, adding too little material will lead to a decline in efficiency. Therefore, we should learn to add material reasonably, so as to ensure production efficiency.

Judging by the sound of plastic industrial shredder

Add material should be an appropriate amount, and learn to judge by the sound of the plastic recycling shredder machine. The production capacity of different models of plastic shredder machine industrial is also very different. For those who do not understand how much should be put, you can test the machine after buying it back, from less to more to test the crushing capacity of the plastic industrial shredder.

Another method is to identify through the sound, if the crushing sound is bigger, it means that there are more materials inside. At this time, if you continue to add material is not allowed, you should wait until the sound is smaller that is less material inside the crushing chamber, and then add material.

Reference plastic recycling shredder machine power feeding

Selective dosing according to power. Some manufacturers will buy conventional plastic industrial shredders to crush large pieces of plastic in order to save costs. Although the conventional plastic recycling shredder machine can meet most of the crushing requirements, occasionally large pieces of plastic should be cut into small pieces and put into the plastic industrial shredder to avoid jamming due to lack of power. If the plastic recycling shredder machine is jammed, it should stop working immediately, and then take out the large pieces of material cut them small, and put them into the plastic shredder machine industrial.