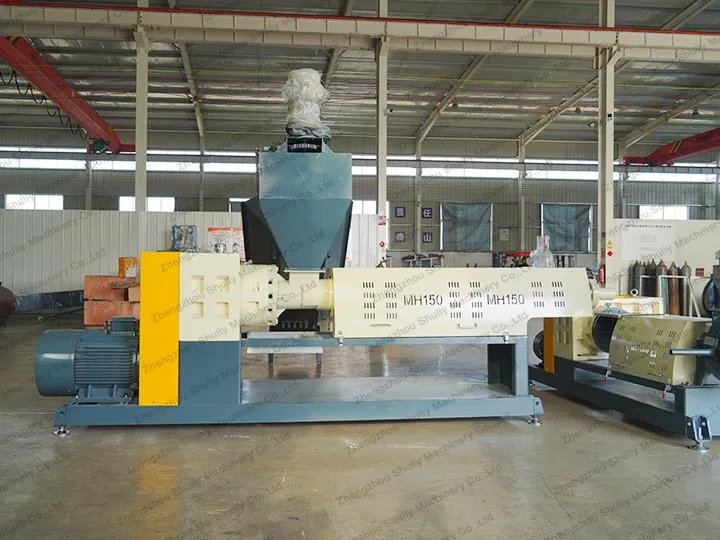

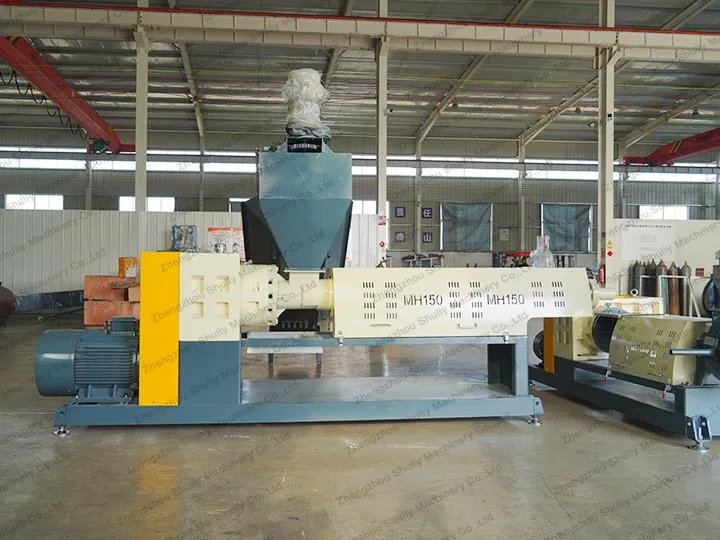

The plastic strand pelletizer is a popular recycling machine designed to recycle rigid plastics such as HDPE, PS, ABS, PE PVC. The output of our PVC granules making machine is 200-300kg/h, 500kg/h, and 1000kg/h.

We can customize machines for other outputs. Welcome to inquire!

Introduction of Plastic Strand Pelletizer

The strand pelletizer machine is a highly efficient plastic waste processing equipment specially designed for converting hard plastic waste into high-quality recycled plastic pellets.

Hard plastic recycled pellets can be widely used in the manufacture of household appliance shells, pipes, components, plastic sheets, etc. It provides reliable, high-quality recycled raw materials for the production of environmentally friendly plastic products.

Working Principle of Plastic Granulator

Feeding conveyor

After being crushed and cleaned, the waste plastics are fed into the feed inlet of the screw extruder by the automatic feeding system. Some of the machines are equipped with forced feeding device to ensure that the fluffy materials enter the screw chamber evenly.

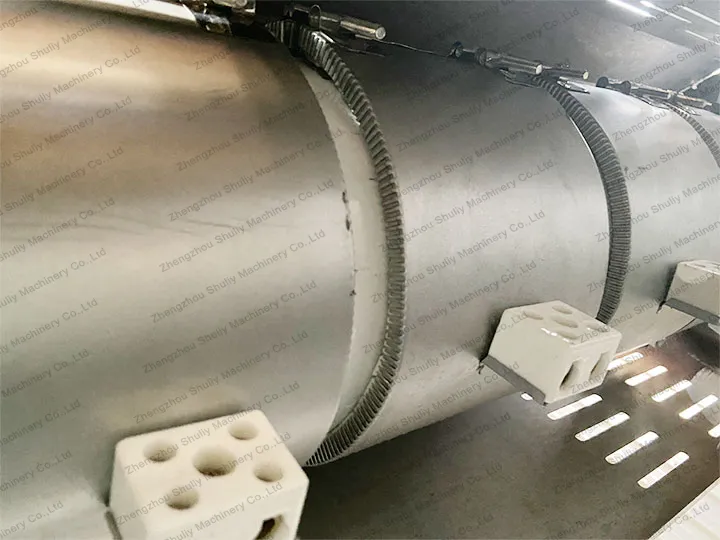

Heating ring

The screw rotates under the motor’s drive, and through the synergistic action of the threaded groove’s push and the barrel’s heating ring, the solid plastic is gradually extruded, frictionally heated, and melted into a viscous fluid.

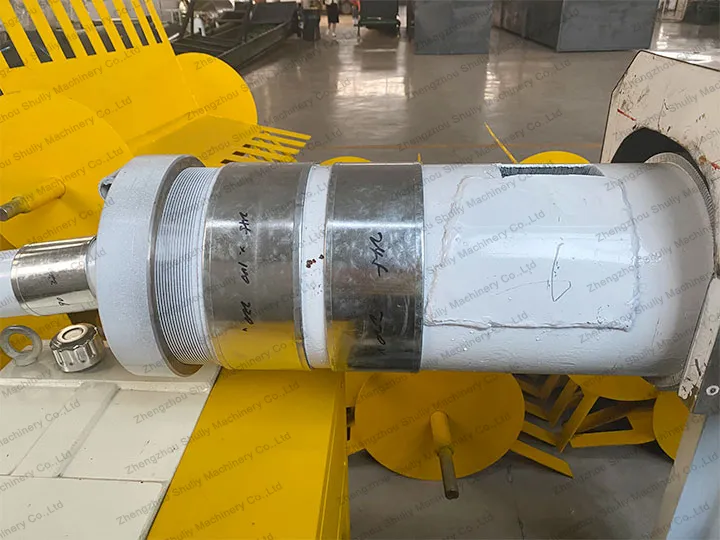

Die head

Molten plastic enters the die head from the front end of the screw and is extruded through a specific shaped die hole to form a continuous thin strip of plastic.

Precise Plastic Strand Pelletizer Temperature Control System

Shuliy PVC granules making machine is equipped with an advanced temperature regulation system to ensure that the plastic material is heated to the proper processing temperature range.

The heating temperature of the strand pelletizer machine can be adjusted according to the different raw materials to achieve the perfect granulation effect. Shuliy plastic strand pelletizer has electromagnetic heating, ceramic heating, electric heating, and other heating methods to choose from.

If you don’t know which heating method is most suitable for your raw material, please get in touch with us to help you.

Strand Pelletizer Machine Hot-selling Model

| Name | Plastic strand pelletizer |

| Model | SL-180 |

| Screw diameter | 180mm |

| Mail shaft speed | 40-50min |

| Main motor | 45kw |

| Capacity | 7t/day/24h |

Of course, we have more than one type of machine. If you want to know more about machine types. You can leave a message on the website, and we will contact you in time.

Plastic Strand Pelletizing Production Line

Integration of the pelletizer into a whole production line provides significant efficiency gains, and this integrated design reduces material transit losses and waiting times by seamlessly integrating the raw material pretreatment, melt extrusion, and cooling and pelletizing processes.

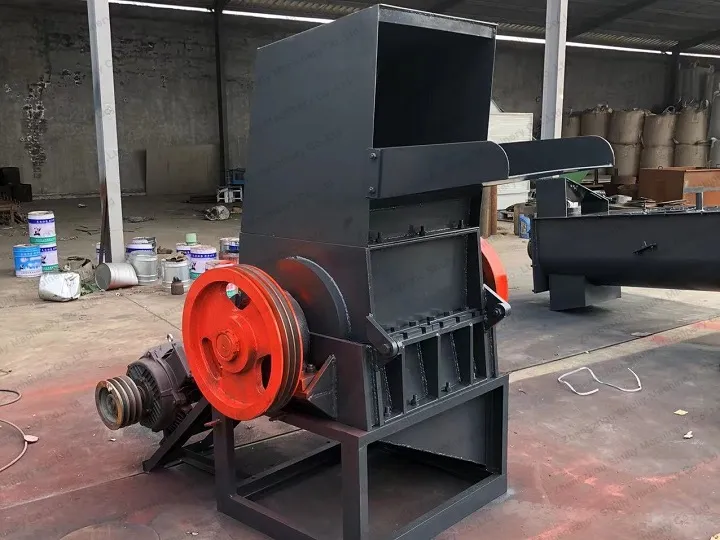

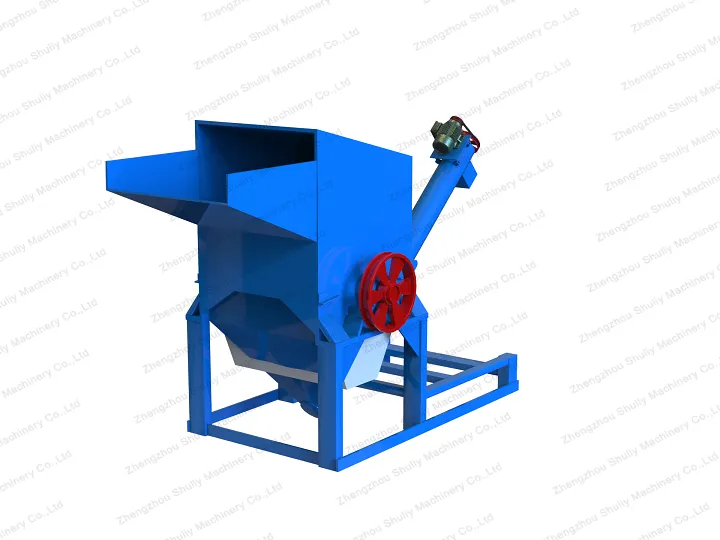

Plastic crusher machine

The crusher is designed for making the plastic waste into pieces.

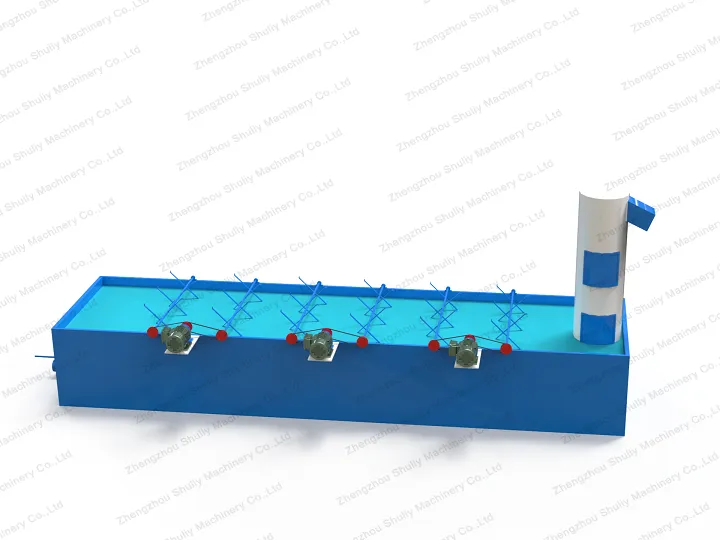

Plastic recycling washing machine

The material includes dirt and dust, and leftover waste, so the waste should be washed to maintain cleanliness.

Plastic granule cutter

The plastic pellet cutting machine is used to cut the plastic strips into homogeneous pellets.

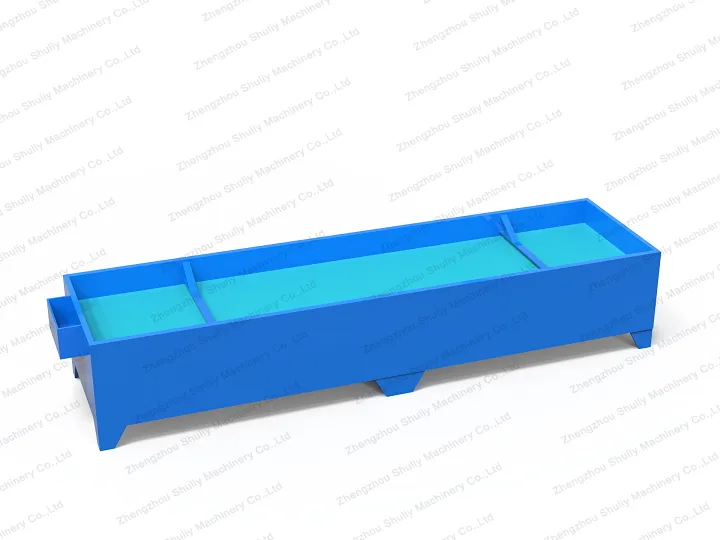

Cooling tank

The strips coming out of the granulator are hot, so they need the cooling tank for cooling and molding.

If you are interested or you would like more detailed information, please feel free to contact us.

Raw Materials of Strand Pelletizer Machine

This plastic strand pelletizer is suitable for a wide range of hard plastic raw materials, including ABS, PS, PVC, HDPE, and other plastics.

Shuliy can customize the right strand pelletizer machine for different types of hard plastic raw materials. Welcome to leave a message to consult. Some of the common raw materials are listed below:

PVC (Polyvinyl Chloride): PVC is widely used in the manufacture of water supply pipes, drainage pipes, cable protection pipes, PVC window frames, door frames, etc.

HDPE (High-Density Polyethylene): HDPE is used to make milk bottles, shampoo bottles, detergent bottles, etc.

PS (Polystyrene): PS plastic is also used in the manufacture of optical disk (CD, DVD) cases, lunch boxes, cups, etc.

ABS (Acrylonitrile Butadiene Styrene Copolymer): ABS is widely used in the manufacture of toys, and housings for household appliances such as hairdryers, telephones, etc.

Successful Cases of PVC Strand Pelletizing Machine

Since our plastic strand pelletizer has been put into the market, it has been successfully exported to many countries, which has brought great success and considerable profit for customers all over the world to carry out plastic pelletizing business.

According to the feedback from users, the Strand Pelletizer shipped to Nigeria has been installed. At present, the machine is running well.

Plastic Strand Pelletizer for Sale

The details of the Shuliy strand pelletizer machine are reflected in its stable structure, wear-resistant parts, and easy operation. Our plastic strand pelletizers are equipped with some advanced technologies, such as intelligent temperature control and efficient cooling systems, which ensure the stability of the processing and the reliability of the granule quality.

Choosing the Shuliy PVC granules making machine for your plastic recycling business is a wise choice.

FAQs of Plastic Granulation Machine

Can soft and hard plastics be pelletized at the same time?

No, soft and hard plastics can’t be pelletized together. Their melting temperatures and flow behaviors differ, risking poor quality or equipment damage. Separate processing is a must.

What is the size of the cut-out pellets? Can it be customized?

Length around 3mm. Can also be customized