The plastic bottle recycling line is a complete set of equipment for converting waste plastic bottles into high-quality PET bottle flakes, which can effectively realize the recycling of waste plastic bottles.

Shuliy Machinery is a professional supplier of plastic recycling machinery, and we can customize it according to your needs. Welcome to contact us.

Introduction to PET Bottle Recycling Line

Our PET bottle recycling line converts waste plastic bottles into PET flakes through a label removing machine, a crusher, a hot washing tank, a frictional washing tank, and a drying machine. This line plays a crucial role in promoting environmental sustainability by reducing plastic waste and conserving resources.

Shuliy Machinery has various types of PET bottle crushing and washing machines, and the whole line can be customized. Welcome to visit our factory.

Working Video of Plastic Bottle Recycling Machine

This video is about this PET bottle recycling line in action, showing how waste bottles are processed into plastic flakes.

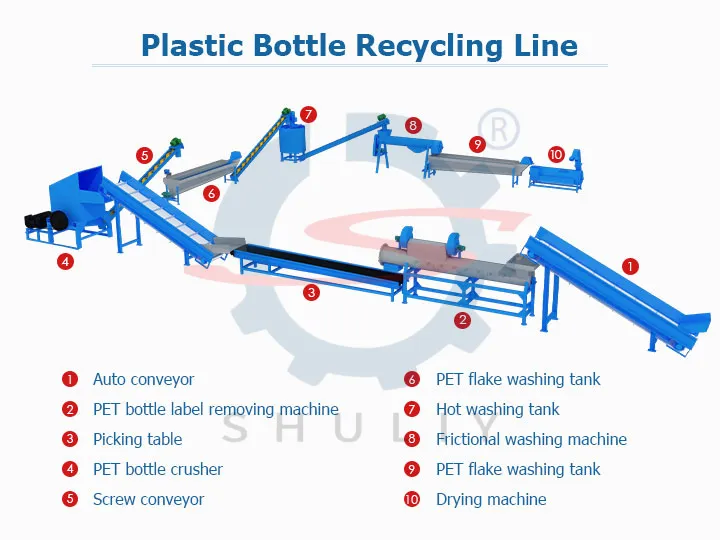

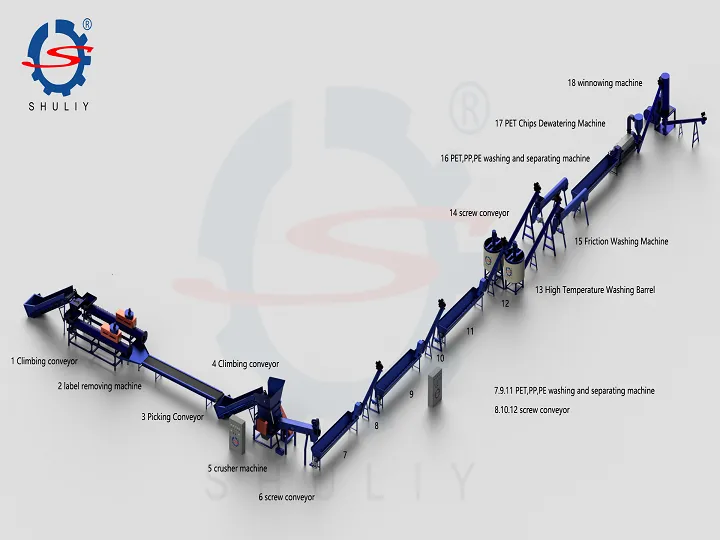

Process Flow of Plastic Bottle Recycling Line

Label removing – crushing – separating bottle caps – washing – drying – storage

- Firstly, if raw material is packed as a bottle package, a plastic baler will set the bottles off and then send them to a plastic bottle label removing machine through a belt conveyor.

- Secondly, manual selection in the PET bottle recycling line is an important step for selecting bottles of other colors and bottles still with labels to maintain the purity of the finished product.

- After that, the crusher will shred these PET bottles into flakes, and then they will be sent to the PET flake washing tank to remove the impurities and caps from the pieces.

- Next, the hot water tank and frictional washing tank are there to clean the flakes further.

- If you have higher requirements for the quality of the final product, you can decide the quantities of these washing tanks.

- The last step of the plastic bottle recycling line is that the drying machine dewatered these PET flakes.

Video of Plastic Bottle Recycling Machine in Live Operation

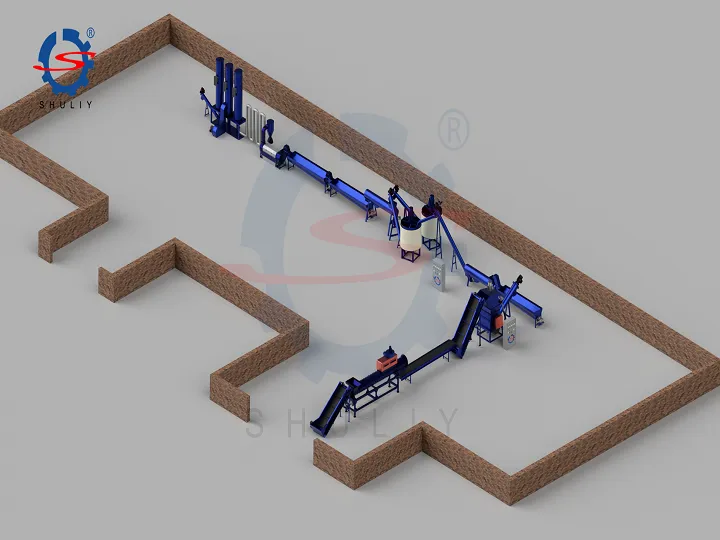

PET bottle crushing washing machine can be adapted to suit your budget and plant size, so feel free to contact us. We can recommend the right plastic bottle recycling line for you.

Raw Materials and Finished Products of rPET Flakes Production Line

Raw Materials

The core raw materials of a rPET flakes production line are used PET bottles, typically purchased in compacted bales. These bottles come from diverse sources, including beverage containers, mineral water bottles, carbonated drink bottles, cooking oil bottles, condiment bottles, and other waste packaging containers made of PET. They often retain labels, caps, and may have residual liquids or stains.

The materials above are not all the raw materials that can be used in the PET bottle recycling plant. If you want to inquire about the materials you have, you can leave a message for us.

Finished Products

The primary finished product of the PET bottle recycling line is PET flakes, which serve as a key raw material for producing recycled PET products. These flakes can be directly used to manufacture polyester staple fibers for textiles like clothing, carpets, and padding materials. They also enable the production of PET sheets for packaging boxes and blister products, and can be re-blown into new PET bottles to achieve circular reuse of beverage packaging.

Main Machines for Plastic Bottle Recycling Line

Plastic Bale Opener for PET Bottle

Unpack and loosen tightly compressed bales of used PET bottles.

The machine uses rotating blades to break apart the bale’s strapping and separate the bundled bottles, converting them into loose individuals for subsequent processing.

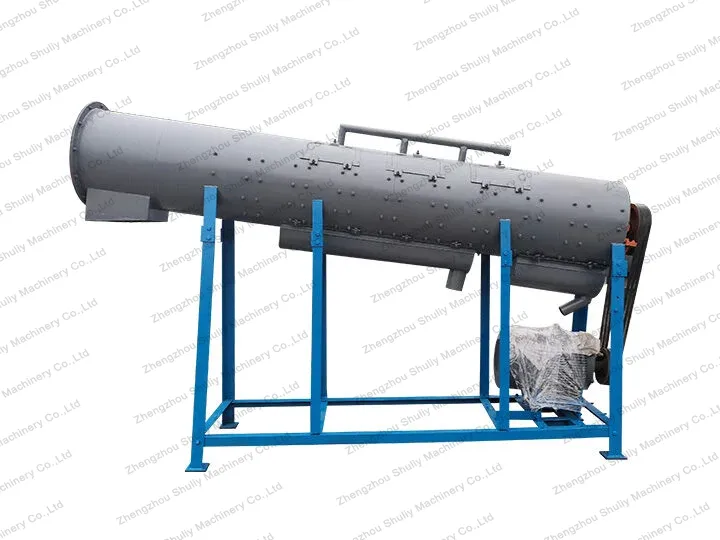

Tumbler Screen for PET Bottle Recycling

The tumbler screen for the PET bottle recycling line serves to screen out fine impurities from PET bottle fragments.

It utilizes a rotating drum with meshed screens to separate tiny contaminants like sand, paper scraps, and cap debris from crushed PET flakes.

Plastic Bottle Label Removing Machine

The machine is usually equipped with an adjustable blade device and can handle different bottle types, such as mineral water bottles and beverage bottles, as well as a wide range of materials, such as paper labels and PVC/PE film labels.

The machine in the PET bottle washing line operates stably and has a 98% de-labeling rate, saving labor.

PET Bottle Crushing Machine

The system is designed to crush recycled plastic bottles into small pieces. The PET bottle crusher is an important piece of equipment in the plastic bottle recycling line.

PP PE Separating Tank

Used to separate PP or PE bottle caps from PET flakes. This process results in pure PET bottle flakes for subsequent recycling.

Hot Washing Tank

This is achieved by adding industrial alkali to hot wash in high-temperature water, thus removing grease from the surface of PET bottle flakes and making them cleaner and more transparent.

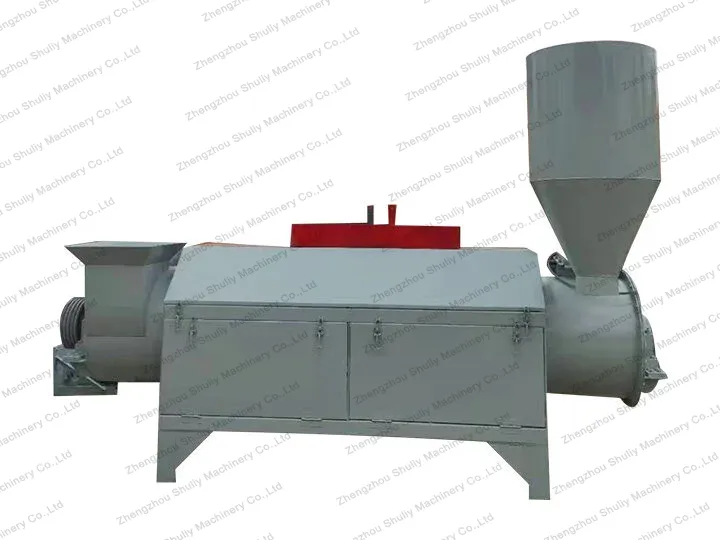

Frictional Washing Machine

The bottles are rubbed and cleaned to dispose of any residual grit, glass, metal, paper dust, or the like on the surface of the bottle.

PET Bottle Washing Machine

A multi-stage cold water rinse removes the industrial alkaline water and impurities from the surface of the bottle flakes, making them cleaner and more contamination-free.

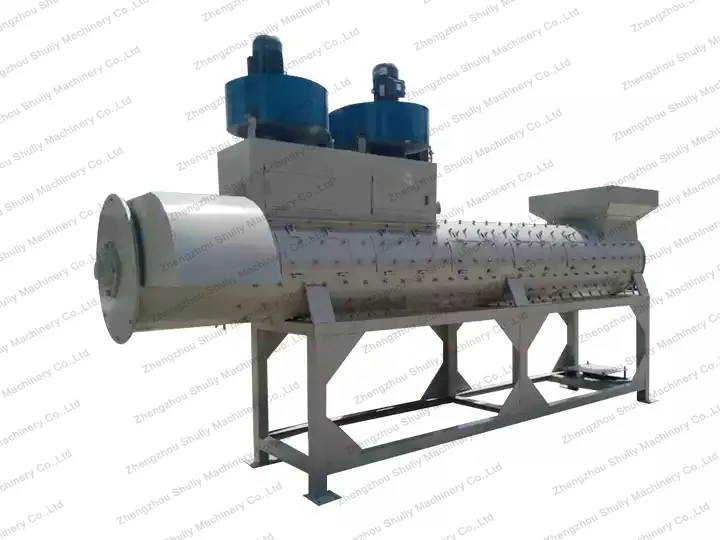

Plastic Dryer Machine

The high-speed rotation of the machine removes the water from the bottle flakes, resulting in dry and clean flakes that can be stored directly in bags.

The final PET bottle washing line can be flexibly adjusted according to the quality requirements, so please feel free to contact us with your ideas and requirements so that we can design a recycling line benefiting your PET bottle recycling plant.

PET Bottle Recycling Machine Parameter

| Item | Details |

| Tumbler Screen for PET Bottle Recycling | Length: 4.5 m Width: 1.5 m Motor power: 7.5 kW Outer wall thickness: 8 mm Blade: 10 mm |

| Plastic Bale Opener for PET Bottle | Length: 4.0 m Width: 1.5 m Height: 2.8 m Motor power: 7.5 + 2.2 kw |

| Plastic Bottle Label Removing Machine | Model: SL-600 Power: 11KW+3KW Capacity: 1-1.2t/h Size: 4000*1800*1600mm Weight: 1500kg |

The parameters above are for example only, we offer different sizes of machines. If you want to know more detailed information, please leave a message on our website, and we will contact you in time.

Advantages of Plastic Bottle Recycling Line

- Automation and continuous operation: from bottle package disassembly to label removal, crushing, washing, and drying, the whole process is linked by conveyor belts and other equipment to minimize manual intervention and enhance processing efficiency.

- High-quality product: Label removal machine combined with manual color selection, effectively eliminating label residue and foreign color bottles, and with multiple cleaning processes to ensure the purity of finished products.

- Customization and flexibility: The number of cleaning tanks in the PET bottle washing line can be increased or decreased independently for different purity requirements. The machine’s color can also be customized according to customer requirements.

FAQs of PET Bottle Washing Line

Is the PET Bottle Washing Plant Business Profitable?

According to statistics, plastic bottles can be sold for over $500 a tonne after a simple process, at a cost of over $200. Therefore, the plastic bottle recycling business is very profitable.

Shuliy Machinery has a complete PET bottle washing plant to help you launch your own business. The investment is not very large. The operation is relatively simple, and the profits are considerable when materials are plentiful.

Output of PET Bottle Crushing Washing Machine

We can supply PET bottle crushing washing machines with outputs ranging from 500 kg/h to 3000 kg/h.

For larger or smaller capacity plastic bottle recycling lines, please contact us for customization.

How many workers do I need to operate the rPET flakes production line, and what level of skill is required?

Labor is a key operational cost. For a standard 1,000 kg/h rPET flakes production line, you will typically need 3-5 workers: one for feeding material, 2-3 for manual sorting, and one to supervise the back-end and packing. The control system is centralized and user-friendly. Our engineers provide 1-2 days of on-site, hands-on training, ensuring your team can operate the entire rPET flakes production line competently.

What are the main wear parts, what is their lifespan, and are they easy and affordable to replace?

The primary wear parts are the crusher blades and label remover knives. Their lifespan depends on the cleanliness of your input material but typically lasts for several months. Our crusher is designed for quick blade changes, and we can supply a professional knife sharpening machine so you can re-sharpen them yourself, drastically reducing replacement costs. We guarantee a long-term supply of all original spare parts at fair prices.

What is the total lead time from placing an order to having the plant operational at my factory?

The total project timeline consists of three main phases:

1. Manufacturing: Typically 45-90 days, depending on the complexity of the line.

2. Ocean Freight: Dependent on your geographical location.

3. On-site Installation & Commissioning: Usually takes 15-30 days.

We will provide a detailed project Gantt chart so you have a clear timeline for every stage.

Do you provide installation and training? My workers have no prior experience.

Yes, this is a core part of our service and a key advantage. We dispatch experienced engineers to your site to supervise the complete PET recycling plant installation, commission the equipment, and provide comprehensive, hands-on training for your operators and maintenance staff. We continue until the PET recycling plant is running smoothly and producing qualified products. We deliver a fully operational system, not just a set of machines.

What is the warranty period, and what happens if a machine fails after the warranty expires?

We provide a standard one-year warranty on all parts against manufacturing defects, effective from the date of final acceptance. More importantly, we offer lifelong technical support. Even after the warranty period, you can contact us anytime for remote troubleshooting via video call. If on-site service is needed, we can dispatch an engineer (at cost), and we guarantee a long-term supply of all spare parts. Our goal is to be your long-term partner in success.