Plastic extrusion equipment screw breakage is a frequently encountered problem in plastic processing, which will lead to production interruption and equipment damage. In this paper, we will analyze the causes of extruders for plastic recycling screw breakage from three aspects: screw manufacturing materials, screw jammed by foreign objects, screw temperature, and provide corresponding preventive measures.

Plastic extrusion equipment screw material

Screws in the extruder for plastic recycling withstand high temperatures and high pressure, so its manufacturing materials must have high strength and wear resistance. If the plastic recycling pelletizing machine screw manufacturing material quality is not up to standard, it is easy to lead to screw fracture phenomenon under long time high-load work.

Preventive measures: Choose high-quality alloy steel materials to manufacture screws, and carry out strict quality testing and wear-resistant treatment of screws to ensure their durability and stability.

Foreign matter in plastic recycling pelletizing machine screw

During plastics processing, sometimes recycled plastics may be mixed with foreign materials, such as metal impurities and hard particles. When the plastic extrusion equipment screw encounters these foreign materials, it may be stuck, resulting in screw breakage.

Preventive measures: Screen and clean the raw materials before adding materials to ensure that the plastic does not contain foreign materials and reduce the possibility of damage to the extruder for plastic recycling screws.

Plastic extrusion equipment screw temperature

Plastic extrusion equipment needs to be preheated before working to ensure that the temperature of the screw and barrel reaches the working temperature required for plastic processing. If the motor is started forcibly when the temperature is not in place, the plastic may stick to the screw and barrel, resulting in the breakage of the screw due to excessive force.

Preventive measures: Strictly follow the operating procedures for preheating to ensure that the plastic recycling pelletizing machine screw and barrel reach the appropriate working temperature before starting the motor.

Summary

Screw breakage is one of the common failures of extruders for plastic recycling in production, but we can reduce the probability of its occurrence by taking appropriate preventive measures. Choosing high-quality screw manufacturing materials, screening and cleaning the screw regularly, and preheating in strict accordance with operating procedures are all keys to reducing the risk of screw breakage. Only by strengthening maintenance and management can we ensure the efficient and stable operation of Plastic extrusion equipment.

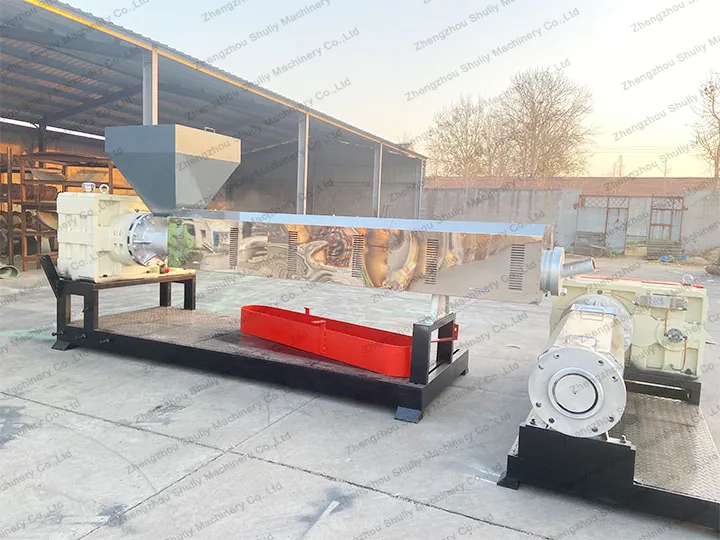

Video of plastic extrusion equipment