The plastic granulating process is sometimes accompanied by odors that come from a variety of sources. In this article, we’ll take a closer look at the causes of these odors and how to manage them effectively.

Possible sources of odor

The odor of raw materials

Plastic waste may carry a variety of odors when it enters the plastic granulating machine as a raw material. These odors may come from the waste materials themselves, such as food packaging, cosmetic containers, etc., which have absorbed the odors of various substances during their use. In addition, there may be chemicals or impurities remaining in the raw material, which may also emit odors.

Heating and melting process

Plastic granulating machines typically require raw materials to be heated to high temperatures in order to melt them and extrude them into pellets. During this process, some plastics may decompose, producing gases that can cause odors. In addition, some plastics may release specific odors at high temperatures, such as the odor of caramel compounds.

Incomplete cleaning

If a plastic granulating machine is not thoroughly cleaned and maintained, residual plastic pellets or scrap may pyrolyze or chemically react in the next production run, creating an odor.

How to manage odors in plastic granulating?

- Handling of raw materials: Use clean, deodorized raw materials and ensure the quality of the raw materials.

- Controlling the heating process: Ensure that the heating and melting process is at the right temperature to reduce decomposition and odor generation.

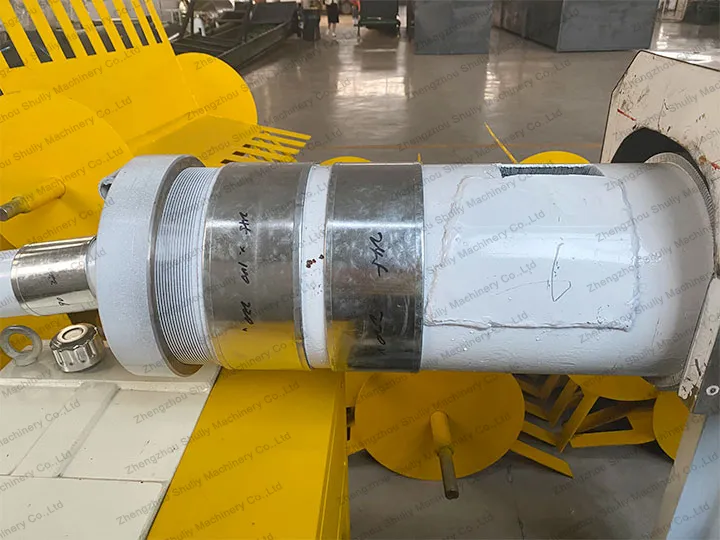

- Maintain Equipment: Regularly maintain and replace worn parts to ensure equipment is in good working order.

- Clean and Ventilate: Clean and ventilate work areas regularly to eliminate odors.

- Use of absorbents: Consider using absorbents to capture odors during the manufacturing process.

By doing so, it is possible to reduce the generation of odors in the plastic granulating process and ensure that the final product is of high quality and environmentally friendly. Effective management of odors not only helps to improve the production environment but also helps to meet environmental regulations and customer needs.