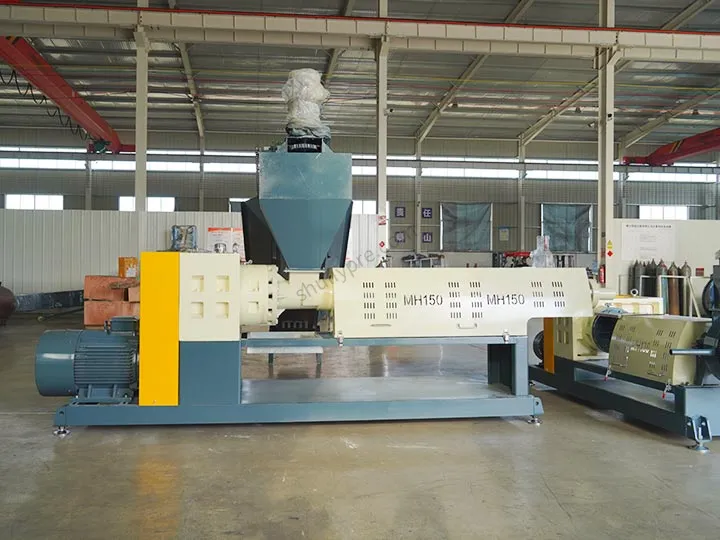

Shuliy woven bag granulator machine, also known as PP pelletizing machine, is a kind of equipment specialized in converting waste woven bags into plastic pellets. Woven bag granulators can be used to recycle discarded plastic bags such as snakeskin bags, tonnage bags, PP raffia bags, cement bags, and so on.

Introduction of Plastic Pelleting Machine

The woven bag granulator machine is specialized equipment for pelleting woven bags, raffia bags, and cement bags.

After the pieces are crushed, the machine heats and plasticizes these plastic bag materials, and then extrudes and cuts them into uniform pellets through the die.

These granules can be used in industries like packaging, handicrafts, and biodegradable materials. It helps convert plastic waste into valuable resources, promoting sustainable utilization of natural materials.

Video of Recycling Granulator Machine

This video is about a plastic granule machine in action, showing how woven bag is processed into plastic pellets.

Working principle of Woven Bag Granulator Machine

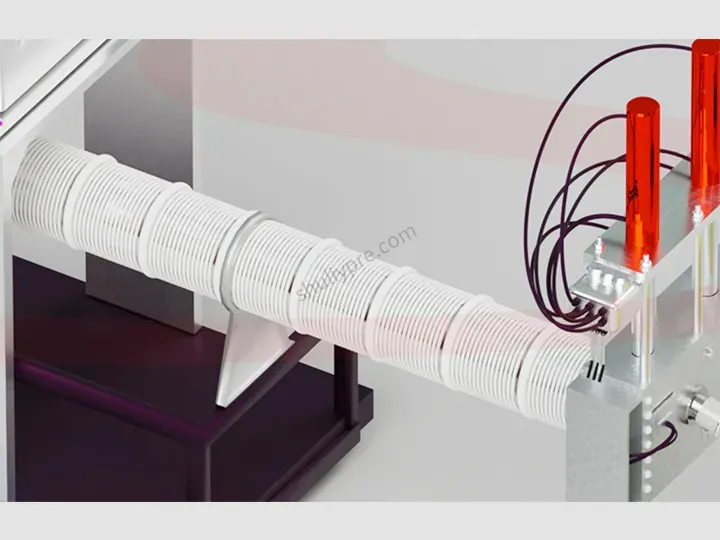

The working principle of the woven bag granulator machine mainly includes the steps of woven bag crushing, melting, extruding, and granulation.

First, the waste woven bags are fed into the crusher, which crushes them into small pieces.

Then, these fragments are fed into the woven bag granulating machine, which converts the waste woven bags into a molten state through the process of heating and melting.z

Finally, the molten plastic is extruded through the shape of the die or the extruder outlet of the woven bag recycling machine and formed into a granular material after cooling.

Woven Bag Recycling Raw Materials Show

The woven bag granulator machine is used for PP, PE woven bags, raffia bags, jumbo bags, plastic bags, cement bags, snake bags, etc.

Working Process of PP Pelletizing Machine

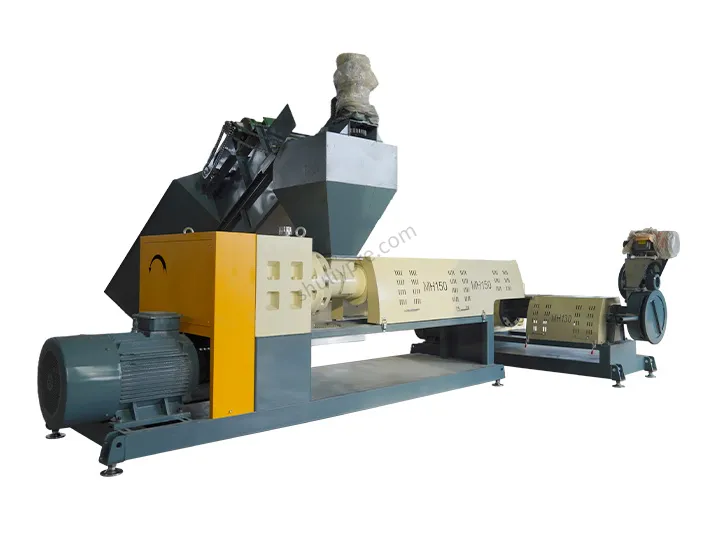

Feeding: the screw in the feeding conveyor sends plastic pieces to granulate continuously and evenly, which ensures the stability of discharging. Also, the machine replaces manual operation and improves output.

Heating: The electromagnetic heating of this recycling granulator machine melts the waste pieces into a paste.

Extruding: This automatic hydraulic die extrudes the paste into stripes for subsequent cutting.

Woven bag pelletizer machine configuration recommendations

Selecting the right woven bag granulating machine requires consideration of the degree of cleanliness of the woven bag and the desired pelletizing effect. The cleanliness of the raw material may influence the choice of type and configuration of the woven bag granulating machine. Here are some suggestions for selecting the right woven bag granulator machine.

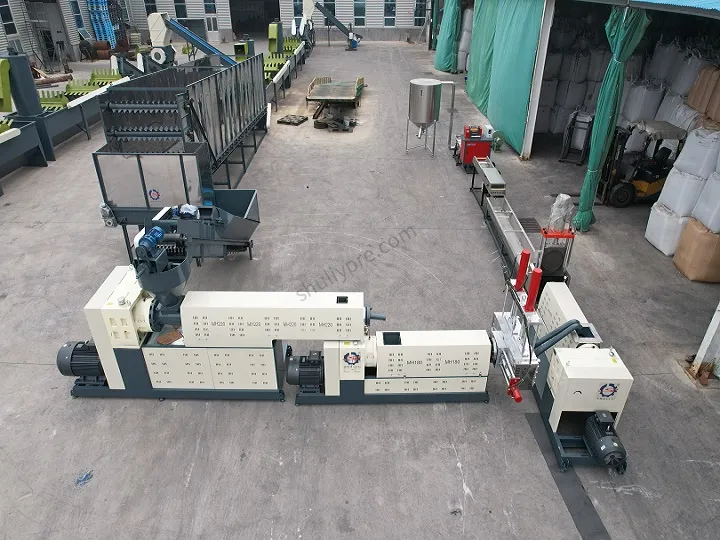

Crushing

If the woven bag contains more impurities or pollutants, it is recommended to choose a woven bag granulator machine with a powerful crushing system. A double-shaft plastic shredder is recommended so that the woven bags do not get tangled in the plastic crusher machine shaft. In addition, soft plastics such as woven bags are generally selected with an automatic feeder, a woven bag pelletizer machine.

Washing

The cleanliness of woven bags can be categorized into two situations: clean woven bags and woven bags with contaminants. Clean woven bags are usually free of obvious contaminants and foreign objects, while woven bags with contaminants may contain impurities, oil, etc. Manufacturers with high-quality requirements for finished products are recommended to configure a plastic washing machine. The cleanliness of the raw material has a greater impact on the plastic pellets.

In addition, Shuliy can customize different recycling solutions according to diverse requirements and meet personalized needs.

The woven bag granulator machine is the main part of the plastic recycling production line. If it is used in conjunction with other machines to form a complete plastic recycling granulating line, the utilization rate of the equipment can be maximized.

If you have any needs in this regard, feel free to contact us.

PP Recycling Granulating Machine Advantages

Efficient and time-saving: The hydraulic die head of this machine does not need to be stopped to change, which saves more time compared with the traditional gear magic head.

Energy-saving and durable: The heating device adopts electromagnetic heating instead of the traditional method of ceramic sheet heating, which is not only energy-saving but also has a longer service life.

Global cases of Recycling Granulator Machine

Shuliy woven bag granulator machine for sale to Saudi Arabia, and our engineers will go to the site to help customers install.

FAQs of Woven Bag Granulator Machine

What is the final product of this line, and what fields can this product be used in?

The final product is plastic pellets. These granules find wide applications across multiple fields. For example, in the packaging industry, the granules are used for producing plastic films and raffia bags; in agriculture, for manufacturing agricultural films and pipes; in daily utilities for processing toys and furniture.

What are the ways to recycle waste woven bags?

If you want to start a pelletizing business from waste woven bags, you can consider the following ways to find waste woven bags:

Waste recycling stations and garbage collection points: Work with your local waste recycling stations, garbage collection points, or garbage disposal centers to obtain waste woven bags.

Supermarkets and retailers: Work with supermarkets, shopping malls, or retailers who usually have large quantities of waste woven bags.

Construction sites and industrial areas: Construction sites and industrial areas often use woven bags to transport building materials or items.

Can the parts of this machine be customized?

Parts of the woven bag granulator machine can be tailored such as the size of the pelletizer, the pellets, the stripes, and the automatic hydraulic die as well as the length of screw in the feeding conveyor.

If you can to know more detailed or other information, pleasse feel free to contact us so that you can get your personalized solutions.