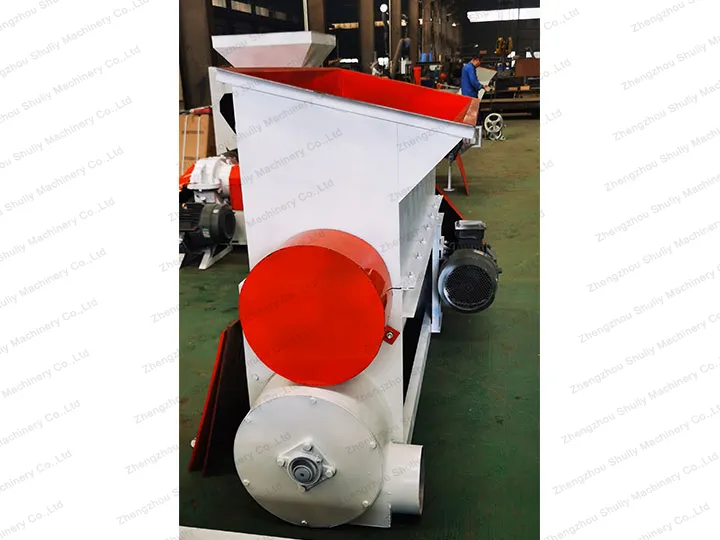

Plastic foam crushers offer the potential to produce a variety of products from recycled foam. The flexibility of this shredder allows for the development of new reuse methods. The Shuliy EPS foam crushing machine tears bulk-expanded polystyrene and many other foams into smaller pieces. These foams come out through a screen before being collected. We offer different screen components. The screen inserts you choose determine the size of foam that can leave the foam shredder machine and continue to be collected.

Introduction of Plastic Foam Crusher

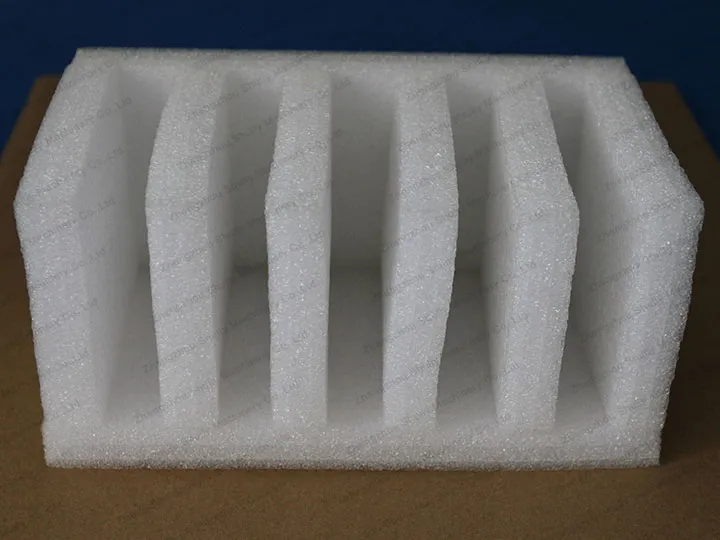

A plastic foam crusher or EPS foam crushing machine is a recycling machine that makes EPS EPE foam blocks into shredded pieces for further recycling, such as extrusion pelletizing. The machine also reduces the volume of the foam for easy transportation.

Shuliy also offers a range of EPS foam crushing machines for the recycling of various scrap materials. Our products include single-shaft shredders, two-shaft shredders, and four-shaft shredders. They are ideal machines for shredding plastic bottles, plastic tapes, plastic drums, and various plastic products. We can customize the foam shredder machine according to the customer’s requirements.

Working Principle of Plastic Foam Crusher

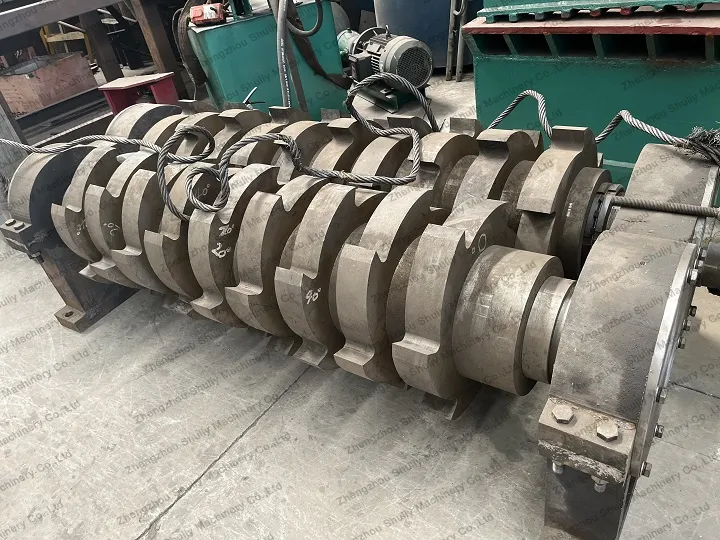

The working principle of the plastic foam crusher is to shear, tear, and extrude the foam material through the high-speed rotating blade or roller to crush the large pieces of EPS, EPE, EPP, and other foams into small particles or fragments, to facilitate the subsequent compression, granulation, or recycling process.

- Feeding: The operator puts large pieces of foam into the machine through the inlet.

- Pre-compression: Foam is fed into the crushing chamber by gravity or screw propeller.

- Crushing: Multiple sets of blades mounted on the spindle rotate at high speeds to quickly cut and tear the foam.

- Screen to control the discharge size: The crushed foam particles are discharged through a screen with an adjustable aperture to control the final discharge size.

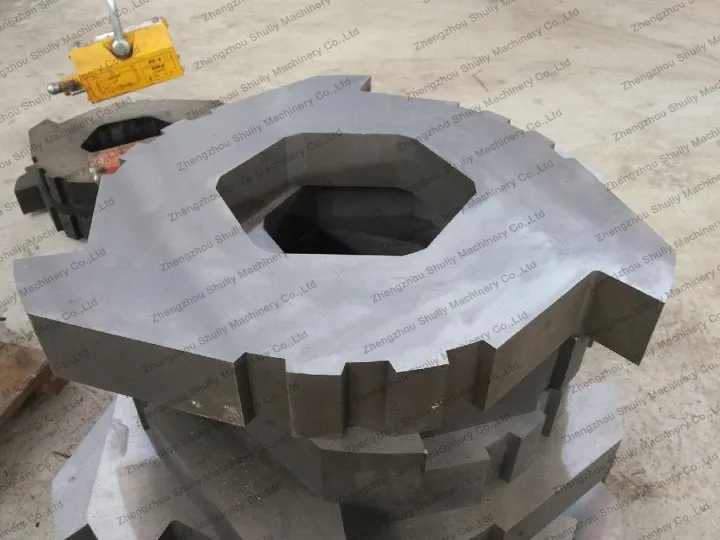

Core Structure and Detailed Design of Styrofoam Shredder

The core structure of the plastic foam crusher includes a reinforced steel frame, a high-torque motor, a rotor system that drives the knife and stator knife, and a replaceable screen unit. These components work together to efficiently crush bulky foam into uniform particles.

High-speed rotary blades

- The tool material is spring steel, high hardness, good wear resistance, and long life.

- The tool supports disassembly and multiple grinding, easy maintenance, and low cost.

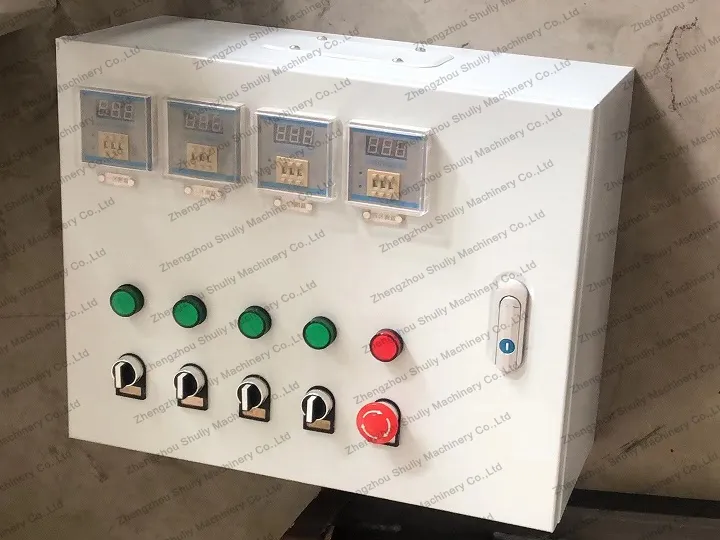

Industrial Control Panels

- The equipment is equipped with a special control box containing digital display instruments, independent control buttons, and an emergency stop system.

- Real-time monitoring of motor status, current and voltage, and running load.

Adjustable screen device

- Use: Control the particle size of foam discharge

- Common aperture: 10 mm- 50 mm (can be customized)

- Material: stainless steel or wear-resistant steel

These parts are the core components of the plastic foam crusher. If you want to know more about the information, please feel free to contact us.

Parameters of EPS Foam Crusher

| Model | Power | Capacity |

| SL-800 | 5.5kw | 150-250kg/h |

| SL-1000 | 5.5kw | 280-350kg/h |

| SL-1500 | 7.5kw | 450-500kg/h |

Optional Configuration of Styrofoam Crusher

| Mahcines | Functions |

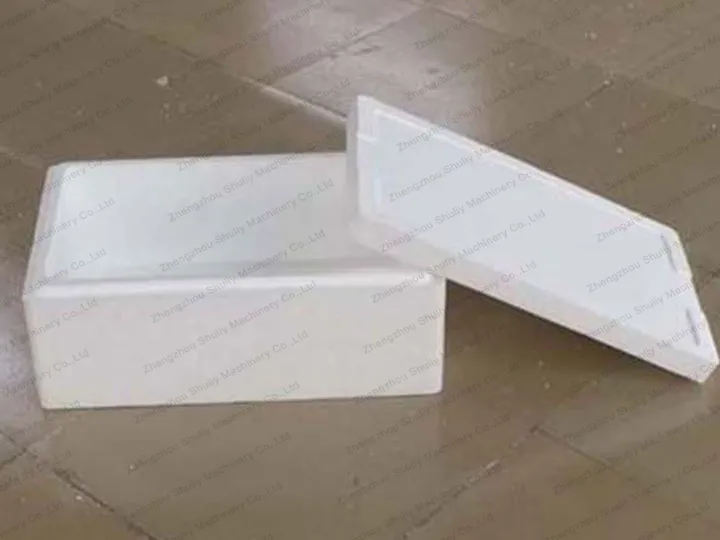

| Foam compactor machine | Styrofoam compactors compress bulky foam waste (e.g., EPS, EPE) into high-density blocks to reduce volume for storage, transportation, or subsequent recycling. |

| Plastic foam extruder | Plastic granulator is used to process waste plastics into reusable plastic pellets for re-production through melting, filtering, drawing, and other processes. |

| Cooling tank | Cooling tanks are used to rapidly cool the extruded plastic strips during the plastic pelletizing process to ensure that they are hardened and molded for easy pelletizing. |

| Plastic granule cutter | A plastic pellet cutter is used to cut cooled plastic strips into uniform granules for subsequent storage, transportation, and reprocessing. |

Raw material of EPS Foam Crushing Machine

Shuliy EPS foam crushing machine can shred EPS, EPE, polyethylene foam, polyurethane foam, memory foam, and most types of foam into smaller pieces. And there is no need to compact the foam like other shredders. The shredder is designed for foam, so it can run continuously without the problems encountered with other methods.

Features of polystyrene shredding machines

| Features of EPS foam shredder | Details of styrofoam crusher |

| Robust tool construction | 1. Equipped with 4 fixed knives and 6 movable knives, it has strong cutting ability for dense or elastic foam materials. 2. The blade material is made of 60Si2Mn high-quality spring steel with excellent wear resistance and toughness. |

| Thickened carbon steel structure body | 1. The fuselage is welded by a 20 mm-thick A3 carbon steel plate, which is durable and not easy to be deformed. 2. Suitable for high-intensity continuous operation to meet the needs of harsh working conditions. |

| Optimized feeding and discharging control | 1. Large size feeding opening (600×500mm), suitable for large foam feeding. 2. Equipped with a 24mm screen (customizable) to control the size of crushed particles. 110mm spindle diameter ensures stable torque and smooth operation. |

| Industrial Grade Performance | 1. 22 kW motor provides continuous power for high-load lines. 2. Capacity up to 800 kg/h for foam granulation or compression lines. |

Styrofoam Shredder Fan

The Shuliy EPS foam crushing machine is equipped with an exhaust blower that conveys the material through the shredder and into a collection bag. This method runs cleanly and bales the shredded foam in one step.

FAQs of Plastic Foam crusher for sale

What is the typical size of crushed foam particles?

The general particle size of the discharged material is 10-50 mm, which can be adjusted by replacing the screen mesh.

Are the blades of the EPS foam shredder easy to replace or sharpen?

Yes, the blades in the styrofoam shredder are removable and support multiple sharpenings and reuse.

Can a styrofoam shredder be connected to a pelletizing line or compression plant?

Yes, the equipment supports linkage with back-end pelletizing lines or compression systems for automated recycling.